335345435

Sep . 29, 2024 01:17 Back to list

OEM One Fiber Braid Hydraulic Hose Suppliers for Durable and Reliable Performance

The Rise of OEM One Fiber Braid Hydraulic Hose Manufacturers

In the dynamic world of hydraulic systems, the importance of reliable and high-performance hoses cannot be overstated. Among the various types of hydraulic hoses available, the OEM one fiber braid hydraulic hose has gained significant attention for its robustness and versatility. This article explores the rise of manufacturers specializing in these hoses, their advantages, and the impact they are having on various industries.

What is an OEM One Fiber Braid Hydraulic Hose?

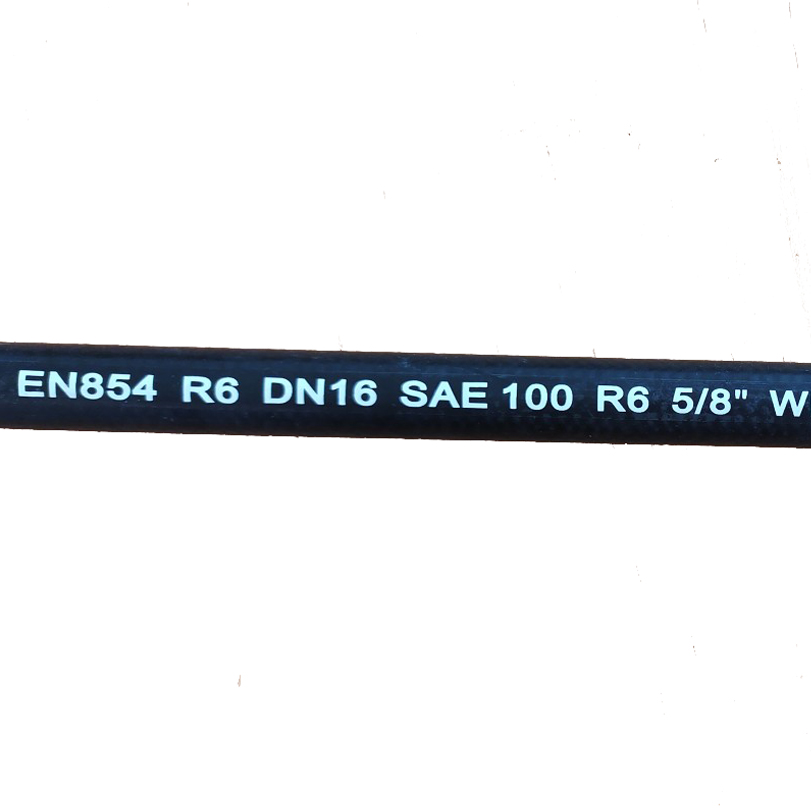

OEM stands for Original Equipment Manufacturer, a term used to describe companies that produce parts or equipment that may be marketed by another manufacturer. When it comes to hydraulic hoses, OEM one fiber braid refers to hoses constructed with a single braid of fiber material, which is then typically surrounded by a rubber or synthetic outer layer. This unique design offers several benefits, making it a popular choice across various applications.

Advantages of OEM One Fiber Braid Hydraulic Hoses

1. High Strength and Durability The one fiber braid design provides exceptional tensile strength, enabling these hoses to withstand high pressures without failure. This characteristic is crucial in hydraulic systems where pressure ratings can exceed several thousand psi.

2. Flexibility One fiber braid hydraulic hoses are remarkably flexible, allowing for easy maneuverability within complex hydraulic systems. This flexibility reduces the risk of kinking or damaging the hose during installation or operation.

3. Lightweight Compared to other braided hoses that utilize multiple layers of materials, the one fiber braid design offers a lightweight alternative. This feature is especially beneficial in mobile machinery where reduced weight can enhance overall efficiency.

4. Corrosion Resistance Many suppliers offer hydraulic hoses treated with anti-corrosion properties, ensuring longevity even in the harshest environments. This resistance to wear and tear is a critical factor for industries such as construction, agriculture, and manufacturing.

5. Cost-Effectiveness With advancements in manufacturing technologies, OEM one fiber braid hydraulic hoses are increasingly produced at competitive prices. This economic benefit makes them an attractive option for businesses looking to optimize their operational costs.

The Manufacturing Landscape

oem one fiber braid hydraulic hose manufacturers

The demand for OEM one fiber braid hydraulic hoses has led to a burgeoning market of specialized manufacturers. Companies have recognized the necessity for high-quality hydraulic hoses that meet strict industry standards. These manufacturers often invest in cutting-edge technologies and quality control processes to ensure their products perform reliably in the field.

Furthermore, many of these manufacturers have adopted sustainable practices, using eco-friendly materials and reducing waste in their production processes. This commitment to environmental responsibility not only enhances their reputation but also aligns with the growing global emphasis on sustainability.

Industry Applications

OEM one fiber braid hydraulic hoses are utilized across a myriad of industries, reflecting their versatility and performance capabilities. Some common applications include

- Construction Equipment From excavators to bulldozers, hydraulic hoses are vital for various machinery operations. The durability and flexibility of one fiber braid hoses make them ideal for the demanding conditions faced on construction sites.

- Agricultural Machinery In agriculture, hydraulic hoses are crucial for tractors, harvesters, and irrigation systems. Their ability to withstand high pressures and resist corrosion makes them suitable for outdoor use.

- Automotive Sector Many hydraulic systems in modern vehicles rely on these hoses, particularly in braking systems and power steering mechanisms where reliability is paramount.

- Manufacturing and Processing In factories and processing plants, these hoses are used in hydraulic presses, conveyors, and processing equipment, underscoring their versatility and essential role in production.

Conclusion

The rise of OEM one fiber braid hydraulic hose manufacturers illustrates the growing need for high-performance hydraulic solutions in various sectors. With their unique advantages, such as strength, flexibility, and cost-effectiveness, these hoses are becoming increasingly integral to modern machinery and equipment. As technology continues to advance and sustainability becomes a focal point, the manufacturers in this sector are well-positioned to meet the evolving demands of the industry. As we move forward, one can expect continued innovation and improvement in hydraulic hose design, contributing to safer and more efficient hydraulic systems worldwide.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025