335345435

Nov . 08, 2024 14:04 Back to list

OEM LPG Hose Supplier Manufacturing High-Quality Flexible Solutions for Your Needs

Exploring the Role of OEM LPG Hose Suppliers and Factories

In the industrial landscape, the demand for specialized equipment and components continues to grow, particularly in sectors that rely on gas distribution, such as liquefied petroleum gas (LPG). One key component within this industry is the LPG hose, which must meet stringent safety and performance standards. Original Equipment Manufacturers (OEM) of LPG hoses play a crucial role in ensuring that these components are produced at the highest quality levels. This article will delve into the significance of OEM LPG hose suppliers and their factories, highlighting the complexities of production, regulatory standards, and the benefits of choosing OEM products.

Understanding LPG Hoses

LPG hoses are essential for transporting gas from one point to another, whether in residential settings, commercial industries, or agricultural applications. These hoses are designed to handle high pressures and must be resilient against various environmental conditions. The materials used in manufacturing LPG hoses, such as rubber and thermoplastics, are selected for their ability to withstand the chemical properties of LPG without degrading over time.

The Role of OEM Suppliers

OEM LPG hose suppliers are dedicated manufacturers that specialize in producing hoses that meet the specifications of various industries. These suppliers work closely with their clients to ensure that the hoses not only comply with relevant safety standards but also align with the specific requirements of their applications. This collaboration allows for tailored solutions that enhance performance and reliability.

One of the advantages of sourcing LPG hoses from OEM suppliers is that they adhere to rigorous quality control processes. From the procurement of raw materials to the final product's testing, OEM manufacturers maintain industry standards to guarantee that their hoses are safe and efficient. This commitment to quality is particularly crucial in the LPG sector, where safety is paramount.

Manufacturing Processes in Factories

The manufacturing processes involved in producing LPG hoses are intricate and involve several steps. Factories utilize state-of-the-art machinery and technology to ensure precision and consistency throughout production. Key stages include

1. Material Selection The selection of high-quality materials is fundamental. Factors such as temperature resistance, flexibility, and chemical compatibility are considered.

2. Extrusion This process involves shaping the selected materials into hose tubes through a technique called extrusion. The exact specifications are critical as they determine the hose’s durability and pressure ratings.

oem lpg hose supplier factory

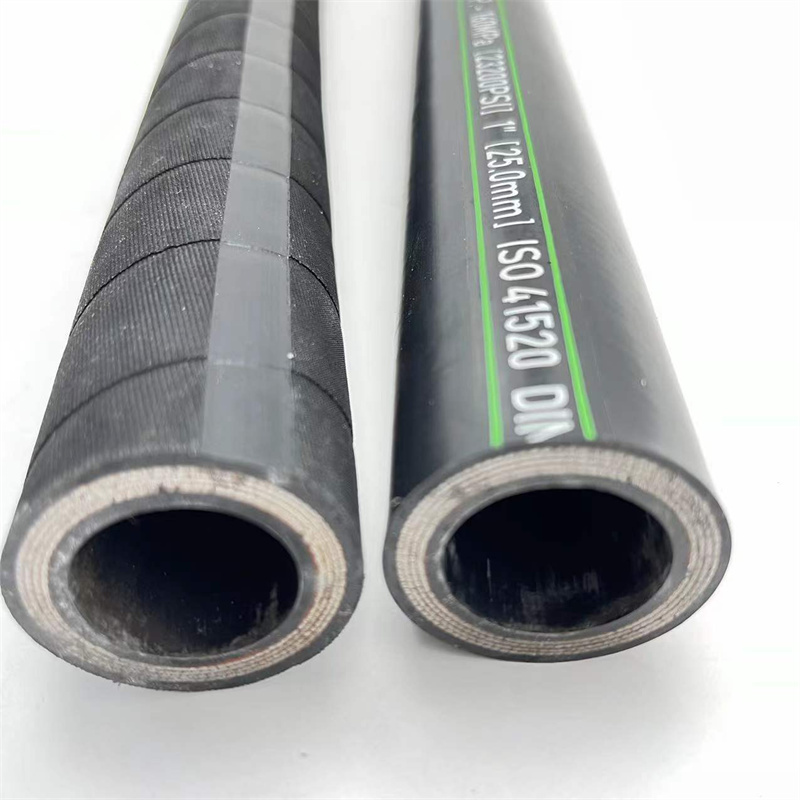

3. Reinforcement To enhance the strength of the hoses, manufacturers often incorporate reinforcement layers. This reinforcement is necessary to prevent bursts and ensure longevity, especially in high-pressure applications.

4. Testing and Quality Assurance After production, hoses undergo rigorous testing to check for leaks, pressure resistance, and overall durability. Compliance with international standards such as ISO and BS regulations is assessed.

5. Customizations Many OEM suppliers offer customization options, allowing businesses to specify length, diameter, fittings, and colors that suit their unique needs.

Benefits of Choosing OEM LPG Hoses

1. Reliability OEM products are synonymous with reliability due to their adherence to quality standards. This reliability is crucial in preventing leaks and ensuring safe operation.

2. Expertise OEM suppliers often have extensive knowledge and experience in the LPG sector, positioning them as trusted advisers to their clients. Their expertise extends to understanding local regulations and industry trends, which can significantly benefit customers.

3. Inventory and Supply Chain Management OEM suppliers maintain efficient inventory systems, ensuring timely delivery of hoses. Their established supply chains also facilitate quick responses to high-demand situations.

4. Support and Service Many OEM manufacturers provide ongoing support, helping customers troubleshoot issues and maintain their hoses effectively over time.

Conclusion

OEM LPG hose suppliers and their manufacturing factories play an essential role in the safety and efficiency of gas distribution systems. By committing to high-quality production processes and understanding the unique needs of their clients, these suppliers ensure that their hoses are reliable and compliant with industry standards. For businesses in need of LPG hoses, selecting an OEM supplier is not just a choice; it is a critical step towards ensuring safety, performance, and peace of mind in their operations. As the LPG industry continues to evolve, the importance of quality and reliable OEM partnerships will only become more significant, paving the way for safer energy solutions globally.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025