335345435

Oct . 22, 2024 01:21 Back to list

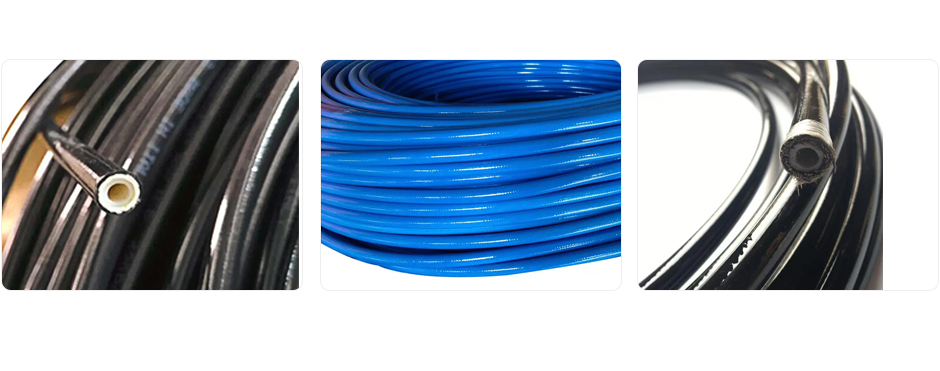

oem lpg gas hose factories

The Evolution and Importance of OEM LPG Gas Hose Factories

In recent years, the demand for liquid petroleum gas (LPG) has surged globally, particularly due to its versatility as a clean energy source. As industries and households increasingly rely on LPG for heating, cooking, and various industrial applications, the importance of high-quality LPG gas hoses cannot be overstated. This is where Original Equipment Manufacturer (OEM) LPG gas hose factories come into play.

The Evolution and Importance of OEM LPG Gas Hose Factories

One of the primary advantages of sourcing LPG hoses from OEM factories is the assurance of quality. OEM manufacturers are typically held to high standards and regulations, ensuring that their products are tested for durability, flexibility, and resistance to high pressures. This is essential, as hoses that fail can lead to serious safety hazards, including leaks and potential explosions. Consequently, investing in OEM products is synonymous with prioritizing safety and reliability.

oem lpg gas hose factories

Moreover, OEM LPG gas hose factories also focus on innovation and technology. Many manufacturers employ advanced materials and production techniques to enhance the performance of their hoses. For example, integrating materials that provide better resistance to harsh environmental conditions can significantly extend the lifespan of LPG hoses. Additionally, modern factories often utilize automation and precision engineering, which not only improves the efficiency of production but also ensures consistent quality across all units produced.

Another critical aspect of OEM LPG gas hose factories is their commitment to customer service and support. These manufacturers typically work closely with clients to develop bespoke solutions tailored to specific needs. Whether it’s customizing hose length, diameter, or material composition, OEM factories can accommodate unique requests to ensure optimal performance in various applications.

Sustainability is also becoming a focal point for OEM LPG gas hose manufacturers. As industries increasingly seek eco-friendly solutions, many factories are adopting sustainable practices in their production processes. This includes using recyclable materials and reducing waste, which aligns with global efforts to minimize environmental impact.

In conclusion, OEM LPG gas hose factories play a pivotal role in ensuring the safe and efficient transport of liquefied petroleum gas. Their commitment to quality, innovation, customer service, and sustainability not only benefits the customers who rely on their products but also contributes to the overall safety and efficiency of the LPG supply chain. As demand for LPG continues to grow, the significance of these specialized factories will only increase, reaffirming their essential place in the energy landscape.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025