335345435

Oct . 12, 2024 09:23 Back to list

oem hydraulic hose crimping machine factories

The Importance of OEM Hydraulic Hose Crimping Machine Factories

In today's fast-paced industrial landscape, the quality of machinery and tools plays a crucial role in ensuring operational efficiency and productivity. Among these, hydraulic hose crimping machines are essential for various applications in construction, manufacturing, and automotive industries. Original Equipment Manufacturer (OEM) hydraulic hose crimping machine factories have emerged as key players in the production of high-quality, reliable machines that meet the diverse needs of industries worldwide.

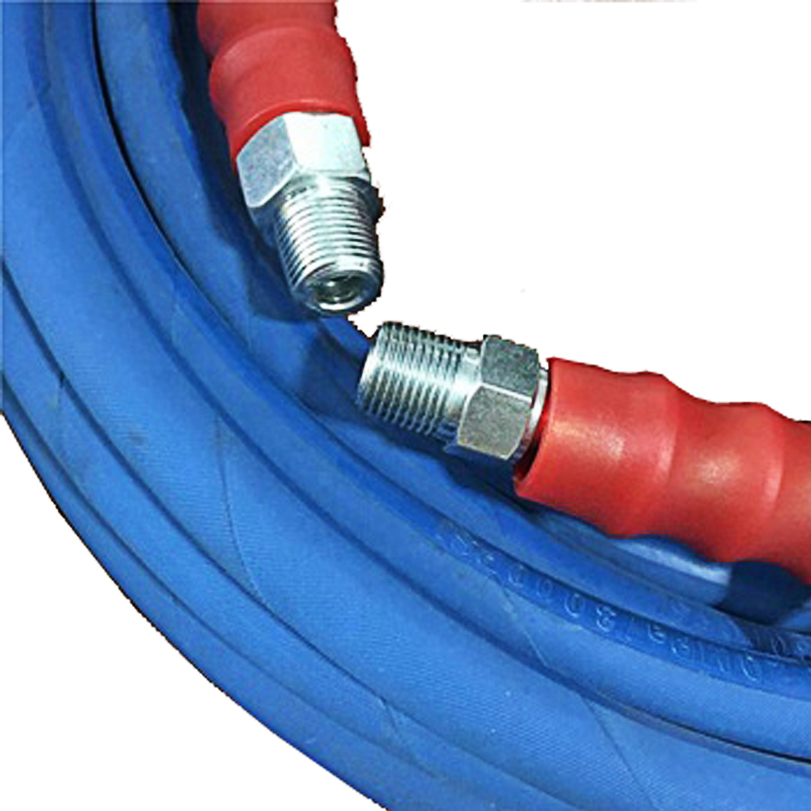

OEM hydraulic hose crimping machines are designed specifically for crimping hydraulic hoses, which are vital components in hydraulic systems. These systems, commonly found in heavy machinery and vehicles, rely on hoses to transfer fluids under pressure. The crimping process ensures that the hose fittings are securely attached, preventing leaks and potential failure during operation. Therefore, the precision and reliability of the crimping machine directly impact the overall performance of hydraulic systems.

One major advantage of sourcing crimping machines from OEM factories is the assurance of quality and compatibility. OEM manufacturers often adhere to strict quality control measures and industry standards, ensuring that their machines are built to last. Additionally, these factories frequently offer customization options, allowing customers to tailor machines to their specific needs. This flexibility helps businesses optimize their production processes, as they can select the features and specifications that best suit their requirements.

oem hydraulic hose crimping machine factories

Moreover, OEM hydraulic hose crimping machine factories typically invest in advanced technology and innovation. By leveraging state-of-the-art manufacturing techniques and materials, these facilities produce machines that are not only efficient but also user-friendly. Features such as digital displays, automatic feeding systems, and enhanced safety mechanisms are becoming increasingly common, making crimping machines easier and safer to operate.

In addition to high-quality machinery, OEM factories often provide excellent after-sales support. This includes maintenance services, spare parts availability, and technical assistance, which are crucial for minimizing downtime and keeping operations running smoothly. Businesses that partner with reliable OEM manufacturers can rest assured that they will receive the support they need, contributing to long-term operational success.

In conclusion, OEM hydraulic hose crimping machine factories play a vital role in the manufacturing and maintenance of hydraulic systems. By ensuring high-quality production, customization options, advanced technology, and robust after-sales support, these factories help industries maintain efficiency and reliability. As businesses continue to seek competitive advantages in a rapidly evolving marketplace, investing in OEM hydraulic hose crimping machines proves to be a wise decision that can lead to improved performance and sustainability.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025