335345435

Dec . 02, 2024 03:02 Back to list

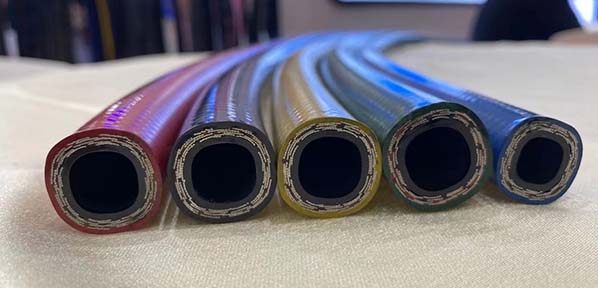

oem hydraulic hose connector

Understanding OEM Hydraulic Hose Connectors

In the realm of hydraulic systems, the efficiency and reliability of these systems depend significantly on the quality and compatibility of their components. One of the vital components within this domain is the hydraulic hose connector. OEM (Original Equipment Manufacturer) hydraulic hose connectors are particularly crucial as they ensure that hydraulic systems operate at their optimal functionality, delivering performance and durability across various applications.

What is an OEM Hydraulic Hose Connector?

An OEM hydraulic hose connector is a specific type of connector designed and manufactured by the original manufacturer of a piece of hydraulic equipment or machinery. These connectors are created to fit perfectly with the hydraulic hoses and equipment they are intended for, ensuring a seamless integration that aftermarket connectors may not guarantee. This precision in design is essential because even minor inconsistencies can lead to leaks or inefficiencies, which can compromise system performance and lead to costly repairs.

Importance of Quality

Using OEM components in hydraulic systems provides numerous advantages. Quality assurance is a primary benefit, as OEM manufacturers adhere to rigorous production standards, resulting in connectors that are more durable and reliable. These components are typically subjected to extensive testing to ensure they can withstand the harsh environments they may encounter, including high pressures and temperatures.

Moreover, OEM products come with a warranty, providing additional peace of mind to users. This warranty often covers defects in material and workmanship, which can save users significant costs over time, especially in critical industrial applications where downtime can result in lost revenue.

Compatibility and Performance

oem hydraulic hose connector

One of the major challenges with aftermarket parts is compatibility. While they may appear similar, aftermarket connectors can vary significantly in dimensions, materials, and performance characteristics. Utilizing an OEM hydraulic hose connector ensures that the component will fit perfectly within the existing system without requiring any modifications. This compatibility extends to performance; OEM connectors are designed to function optimally with the specific hydraulic hoses and systems for which they were manufactured.

In environments where precision is critical, even the slightest variation in connector fit can lead to pressure drops, reduced flow rates, and increased wear on other components. By opting for OEM connectors, businesses can avoid such issues and maintain the required performance levels, particularly in industries such as construction, manufacturing, and agriculture.

Cost-Effectiveness in the Long Run

At first glance, OEM hydraulic hose connectors may seem more expensive than their aftermarket counterparts. However, it’s essential to consider the long-term implications of this investment. The durability and reliability of OEM connectors often translate to lower maintenance costs and fewer replacements over time. When you factor in the potential costs associated with equipment downtime and the impacts of compromised performance, OEM connectors can prove to be a more cost-effective solution.

Additionally, using OEM connectors contributes to the overall health of the hydraulic system, minimizing wear and tear on other components. Maintaining system integrity helps extend the lifespan of the entire hydraulic system, resulting in further cost savings.

Conclusion

In conclusion, OEM hydraulic hose connectors play an indispensable role in maintaining the efficiency and reliability of hydraulic systems. Their superior quality, ensured compatibility, and long-term cost-effectiveness make them the preferred choice for professionals in various industries. Investing in OEM components not only optimizes system performance but also provides peace of mind against potential failures and operational setbacks. As industries continue to advance technologically, the importance of using high-quality, reliable components like OEM hydraulic hose connectors cannot be overstated. In a world where efficiency is key to success, ensuring that your hydraulic systems are equipped with the best components is crucial for sustained operational excellence.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025