335345435

Oct . 12, 2024 13:09 Back to list

oem high quality hydraulic hose crimping machine

OEM High Quality Hydraulic Hose Crimping Machine

In the modern industrial landscape, the need for reliable and high-quality machinery has never been more critical. Among such crucial equipment is the hydraulic hose crimping machine, a vital tool used in various industries, including automotive, aerospace, construction, and manufacturing. The OEM (Original Equipment Manufacturer) high-quality hydraulic hose crimping machine stands out for its precision, durability, and operational efficiency.

Understanding Hydraulic Hose Crimping Machines

A hydraulic hose crimping machine is designed to crimp hydraulic hoses and fittings, thereby ensuring a secure and leak-proof connection. The process of crimping involves applying pressure to the hose around the fitting, which creates a mechanical bond that can withstand high pressure and extreme operating conditions.

These machines come in various sizes and capacities, catering to different operational needs. They often incorporate advanced technology for better performance, including digital displays for precise measurement, different crimping dies for versatility, and quick-change systems for efficiency.

Importance of OEM Quality

Choosing an OEM high-quality hydraulic hose crimping machine offers numerous advantages. OEM manufacturers are known for their commitment to quality and reliability. They utilize top-grade materials and state-of-the-art technology, ensuring that the machines perform consistently over time. Here are a few key benefits of opting for OEM machines

1. Precision Engineering OEM crimping machines are engineered to provide accurate crimping, reducing the risk of failures caused by improper fittings. This precision is crucial in industries where safety is paramount.

oem high quality hydraulic hose crimping machine

2. Durability These machines are built to last. The use of high-quality components means they can withstand the rigors of continuous operation without significant wear and tear. This longevity translates to lower operational costs and reduced downtime.

3. Enhanced Efficiency OEM machines are often designed with features that improve operational efficiency. Quick setups, user-friendly controls, and customized settings contribute to faster production rates and increased productivity.

4. Comprehensive Support and Service OEM manufacturers typically offer extensive customer support, including training, maintenance, and servicing. This level of support can be invaluable for businesses that depend on these machines for their daily operations.

5. Compliance with Industry Standards OEM hydraulic hose crimping machines usually meet high industry standards and regulations. This compliance ensures that the end products are safe and reliable, which is particularly important in critical applications.

Conclusion

Investing in an OEM high-quality hydraulic hose crimping machine is a smart decision for any business that requires efficient and reliable hose crimping processes. With their precision engineering, durability, and enhanced efficiency, these machines not only streamline operations but also contribute to overall safety and reliability in industrial applications.

As industries continue to evolve and demand higher standards of quality, having the right equipment becomes vital. Therefore, choosing an OEM hydraulic hose crimping machine is not just an investment in machinery; it’s an investment in the future success and reliability of your operations. Whether you are in construction, manufacturing, or any other sector that requires hydraulic hose assemblies, the quality and performance of your crimping machine can significantly impact your efficiency and output.

In summary, when looking for a hydraulic hose crimping machine, prioritize OEM options that guarantee high quality, robust performance, and excellent customer support. The benefits of such a machine will reverberate throughout your operation, enhancing productivity and safety in the long run.

-

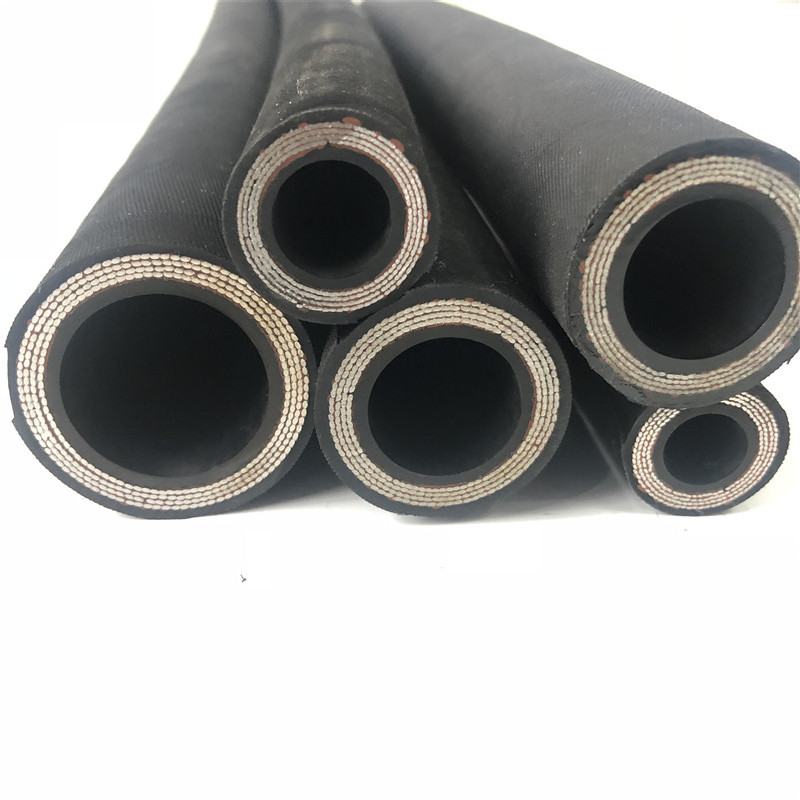

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025