335345435

Nov . 16, 2024 07:12 Back to list

oem high pressure thermoplastic hose suppliers

OEM High Pressure Thermoplastic Hose Suppliers A Comprehensive Guide

In various industrial applications, the need for robust and reliable hose solutions is paramount. One component that stands out in fulfilling these requirements is the high-pressure thermoplastic hose. As industries evolve and demand more durable and efficient components for fluid transfer, the reliance on original equipment manufacturer (OEM) suppliers for these hoses has increased significantly. This article delves into the significance of OEM high pressure thermoplastic hose suppliers, exploring their benefits, application areas, and key considerations when choosing a supplier.

Understanding High Pressure Thermoplastic Hoses

High pressure thermoplastic hoses are engineered to withstand extreme conditions, making them suitable for a wide range of applications such as hydraulic systems, pneumatic systems, and various industrial processes. These hoses are constructed using thermoplastics which offer excellent chemical compatibility, lightweight properties, and flexibility. The ability to endure high pressures while maintaining a consistent performance makes them ideal for applications in sectors such as aerospace, automotive, construction, and manufacturing.

Benefits of Choosing OEM Suppliers

1. Quality Assurance OEM suppliers are known for adhering to high manufacturing standards. Their products typically undergo rigorous testing to ensure they meet specific industry norms and customer requirements. By opting for OEM high pressure thermoplastic hoses, businesses can trust that they are acquiring reliable and durable products.

2. Customization Different industries have varied requirements when it comes to hose specifications. OEM suppliers offer customization options to meet specific needs, such as custom lengths, diameters, and pressure ratings. This adaptability ensures that businesses can find the perfect hose solution tailored to their applications.

3. Technical Support Partnering with reputable OEM suppliers often comes with the added benefit of access to technical expertise. These suppliers have knowledgeable staff who can assist in selecting the right hose, provide installation guidance, and offer maintenance tips. This support can be invaluable in ensuring optimal performance and longevity of the hoses.

4. Cost-Effectiveness While some may view OEM products as more expensive upfront, the long-term benefits often outweigh the initial costs. High-quality hoses tend to have longer lifespans and reduced failure rates, resulting in lower replacement and downtime costs. This financial efficiency is crucial for businesses looking to maintain productivity.

oem high pressure thermoplastic hose suppliers

Key Considerations When Choosing a Supplier

1. Reputation and Experience Research the background of potential suppliers. Established OEM suppliers with a strong reputation in the industry are typically more reliable. Look for suppliers who have successfully served clients in your specific niche.

2. Product Range Ensure that the supplier offers a comprehensive range of high pressure thermoplastic hoses. A wide selection implies that they can cater to diverse industry needs and provide you with multiple options.

3. Compliance and Certifications Verify that the hoses meet relevant regulatory standards and possess necessary certifications. Ensuring compliance with the latest safety and environmental regulations is critical for any industrial application.

4. Warranty and After-Sales Service Check the warranty policy provided by the supplier. A solid warranty indicates confidence in product quality. Additionally, inquire about after-sales support for troubleshooting or replacement needs.

5. Customer Reviews and Testimonials Review comments and success stories from previous clients. Positive testimonials can provide insights into the quality of products and level of customer service a supplier provides.

Conclusion

Choosing the right OEM high pressure thermoplastic hose supplier is crucial for ensuring the efficiency and safety of your operations. By understanding the advantages of these hoses and considering key factors when selecting a supplier, businesses can make informed decisions that lead to enhanced productivity and reduced operational costs. Partnering with a reputable supplier who prioritizes quality and customization can lead to significant benefits in the long run, making it a worthwhile investment for any industrial application.

-

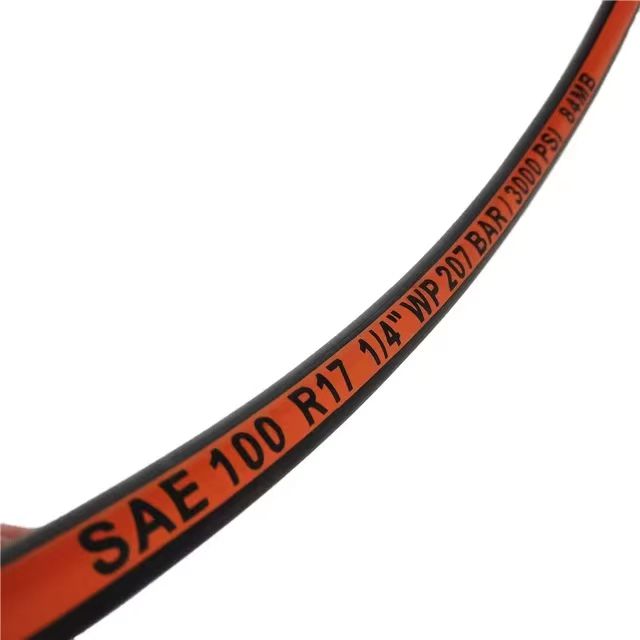

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025