335345435

Oct . 12, 2024 00:19 Back to list

oem high pressure rubber hydraulic hose

High-Pressure Rubber Hydraulic Hoses An OEM Perspective

In the realm of industrial applications, high-pressure rubber hydraulic hoses play a pivotal role in ensuring the efficient transmission of fluid power. These hoses are essential components in various machinery and equipment, serving as the arteries through which hydraulic fluids are transported under substantial pressure. When considering the manufacturing of these hoses, Original Equipment Manufacturers (OEMs) must focus on durability, flexibility, and safety to meet the demands of their clients and end-users.

High-Pressure Rubber Hydraulic Hoses An OEM Perspective

One of the key advantages of rubber hydraulic hoses is their resistance to wear and abrasion. In demanding environments, such as construction sites or manufacturing plants, hoses are subject to frequent movement and exposure to various substances. High-quality rubber materials can withstand these challenges, extending the lifespan of the hoses and reducing downtime for maintenance or replacement. Furthermore, the use of high-performance rubber compounds can enhance the hose's resistance to oils, chemicals, and UV rays, making them suitable for a wider range of applications.

oem high pressure rubber hydraulic hose

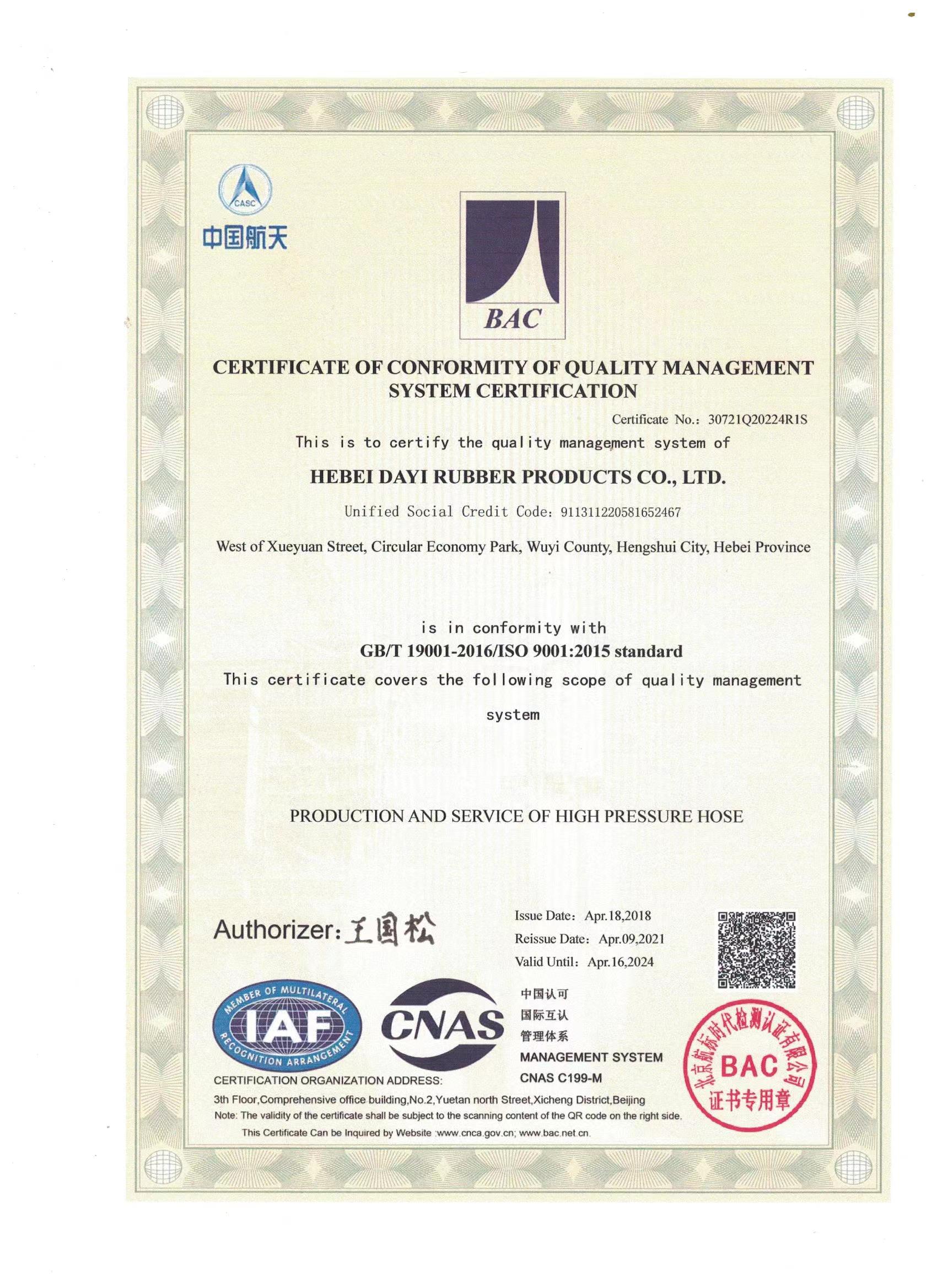

Safety is a paramount concern in the design and manufacturing of high-pressure rubber hydraulic hoses. OEMs must adhere to strict regulations and industry standards to ensure that their products can operate safely under high-pressure conditions. This includes rigorous testing procedures to assess the performance of the hoses under extreme conditions, as well as quality control measures during the manufacturing process. By prioritizing safety, OEMs not only protect the end-users from potential hazards but also build a reputation for reliability in the marketplace.

In addition to performance and safety, OEMs must remain competitive by staying ahead of technological advancements. Innovations in materials science and manufacturing processes continue to enhance the performance of hydraulic hoses. For example, advancements in non-leak coupling systems and lightweight materials are helping to reduce overall system weight while maintaining strength and durability.

In conclusion, high-pressure rubber hydraulic hoses are indispensable in various industrial applications. OEMs must combine engineering expertise with a commitment to quality and safety to produce hoses that meet the demanding requirements of today’s hydraulic systems. By continually improving their products and embracing technological innovations, OEMs can ensure that they meet the evolving needs of their customers while contributing to safer and more efficient industrial operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025