335345435

Nov . 15, 2024 21:01 Back to list

oem high pressure rubber hose

Understanding OEM High Pressure Rubber Hoses Applications and Benefits

In today’s industrial landscape, the versatility and reliability of OEM high pressure rubber hoses have made them essential components in various applications. These specialized hoses are designed to withstand high pressures, making them ideal for a wide range of industries, including automotive, construction, manufacturing, and agriculture. This article will explore the characteristics, applications, and advantages of OEM high pressure rubber hoses.

Characteristics of OEM High Pressure Rubber Hoses

OEM high pressure rubber hoses are typically constructed from high-quality rubber compounds that are engineered to endure extreme pressures and temperatures. These hoses are often reinforced with synthetic fibers, which contribute to their tensile strength and resistance to abrasions, kinks, and weathering. The inner lining is designed to resist corrosion and chemical damage, making it suitable for transporting various fluids, including water, oil, and chemicals.

The manufacturing process of these hoses follows stringent standards to ensure consistent performance and reliability. OEM (Original Equipment Manufacturer) suppliers focus on creating products that meet the specific requirements of their clients, providing custom solutions tailored to specific needs. This attention to detail guarantees that the hoses will perform optimally in their intended applications.

Applications of OEM High Pressure Rubber Hoses

High pressure rubber hoses are indispensable in several sectors. In the automotive industry, they are commonly used in hydraulic systems, coolant lines, and fuel delivery systems. Their ability to handle high-pressure fluids safely makes them a critical component in maintaining vehicle performance and reliability.

In construction and manufacturing, these hoses are used to power machines and transport materials. For instance, they are found in concrete pumping equipment and heavy machinery that require high-pressure hydraulic systems for operation. Their durability ensures that they can withstand the tough conditions often present on construction sites.

oem high pressure rubber hose

The agricultural sector also relies heavily on high pressure rubber hoses for irrigation and chemical application processes. These hoses can efficiently deliver water, fertilizers, and pesticides under pressure, facilitating effective crop management.

Advantages of OEM High Pressure Rubber Hoses

One of the primary benefits of using OEM high pressure rubber hoses is their durability. Designed to endure extreme conditions, they minimize downtime and maintenance costs, ensuring smoother operations. Additionally, the flexibility of these hoses allows for easy installation and routing, even in complex systems.

Another significant advantage is their versatility. OEM high pressure rubber hoses can be customized for different temperatures, pressures, and fluid types, making them suitable for various applications. This adaptability reduces the need for multiple types of hoses, simplifying inventory management for businesses.

Furthermore, investing in high-quality OEM hoses can lead to enhanced safety. Poor-quality hoses can fail under pressure, posing risks to personnel and equipment. By choosing reliable OEM products, companies can ensure a safer working environment.

Conclusion

OEM high pressure rubber hoses play a crucial role across multiple industries, offering reliability, durability, and versatility. Their ability to withstand extreme conditions and transport various fluids makes them indispensable in automotive, construction, manufacturing, and agricultural applications. As industries continue to evolve, the demand for high-quality, tailored rubber hoses is likely to grow, highlighting the importance of investing in OEM solutions for optimal performance and safety.

-

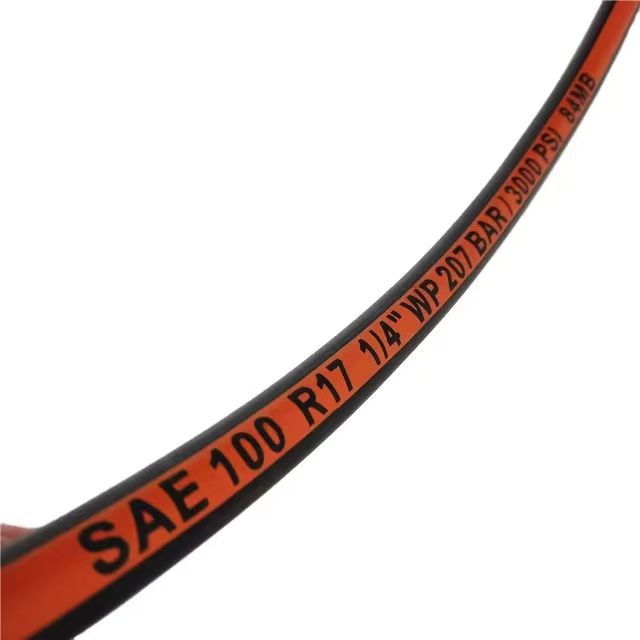

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025