335345435

Oct . 30, 2024 21:30 Back to list

oem en857 1sc factories

Understanding OEM EN857 1SC Factories

Introduction to OEM and EN857 1SC Standards

Original Equipment Manufacturer (OEM) is a term used to describe companies that produce components or products that are used in another company’s end product. These manufacturers are critical in ensuring that various industries, particularly automotive, construction, and oil & gas, receive high-quality components that meet precise specifications.

On the other hand, EN857 1SC is a standard specifically related to high-pressure hydraulic hoses. The EN857 standard specifies the requirements for rubber hoses used for hydraulic applications, and the 1SC designation indicates a specific construction type of these hoses. Understanding these standards is essential for OEMs, as it ensures their products meet safety and performance requirements.

The Importance of EN857 1SC Hoses

Hydraulic hoses play a fundamental role in numerous applications, transferring fluid under high pressure. EN857 1SC hoses are particularly designed to handle applications requiring flexibility while maintaining high-pressure tolerance. They are often utilized in various sectors, including agriculture, mining, and construction, where machinery operates under extreme conditions.

The characteristics of EN857 1SC hoses include a synthetic rubber inner tube, a layer of textile braiding for reinforcement, and a cover that guards against external factors like abrasion, weathering, and chemicals. This design not only ensures durability but also enhances safety, making these hoses essential in industrial applications.

OEM Factories The Backbone of Quality Production

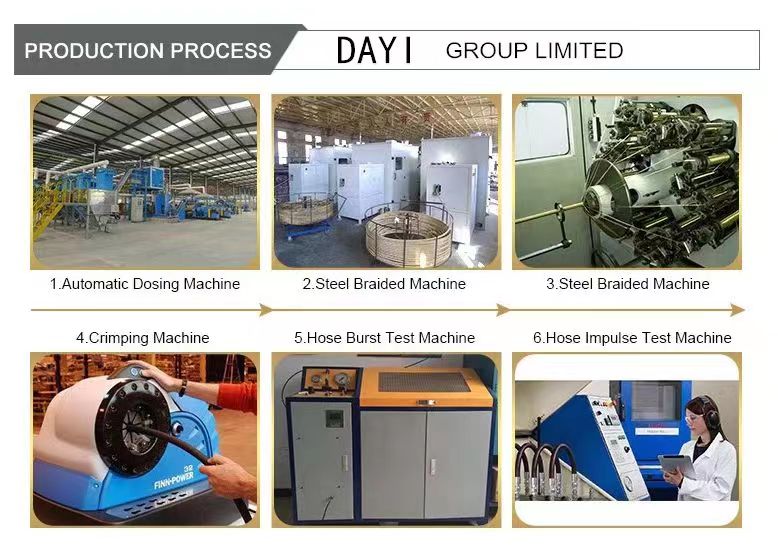

OEM factories specializing in the production of EN857 1SC hoses serve various clients, from multinational corporations to smaller, niche manufacturers. These factories are equipped with advanced manufacturing technologies and adhere to strict quality control procedures to ensure compliance with international standards.

oem en857 1sc factories

The manufacturing process typically involves the selection of high-quality raw materials, precise engineering, and rigorous testing. OEMs often collaborate with their clients to customize products to meet specific needs, resulting in tailor-made solutions for hydraulic applications. This partnership is vital to achieving long-term success and reliability in the field.

Challenges Faced by OEM EN857 1SC Factories

Despite the advancements in manufacturing, OEM EN857 1SC factories face several challenges. One significant challenge is meeting the ever-increasing demand for high-quality, durable hydraulic hoses while keeping production costs competitive. Fluctuations in the prices of raw materials can also impact production budgets and timelines.

Additionally, adherence to environmental regulations is becoming increasingly important. Manufacturers must strategize to minimize waste and emissions, often requiring investment in cleaner technologies. Investing in sustainable practices not only addresses regulatory requirements but also satisfies consumers who are more environmentally conscious.

Future Trends in OEM EN857 1SC Manufacturing

As technology advances, OEM EN857 1SC factories are likely to incorporate more automation and smart manufacturing practices. This will enhance efficiency, reduce errors, and allow for more precise production. The trend of Industry 4.0—characterized by interconnected machinery and data analytics—will enable manufacturers to optimize their processes and improve product quality.

Moreover, the rise of electric and hybrid machinery will influence the design and specifications of hydraulic hoses. OEMs must stay ahead of these trends to ensure their products not only meet current standards but are also future-proof for the evolving market demands.

Conclusion

In summary, OEM EN857 1SC factories play a crucial role in producing hydraulic hoses essential for numerous industries. By adhering to stringent quality standards and responding to market challenges with innovative solutions, these manufacturers contribute significantly to the safety and efficiency of hydraulic applications. As the industry evolves, those who embrace technological advancements and sustainable practices will likely spearhead the future of hydraulic hose manufacturing.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025