335345435

Nov . 30, 2024 03:57 Back to list

Top Manufacturers of OEM EN856 4SP Hydraulic Hoses and Accessories

Understanding OEM EN856 4SP Manufacturers A Comprehensive Overview

In the realm of hydraulic hoses and their applications, OEM EN856 4SP plays a pivotal role in ensuring high performance and durability. This standard is widely recognized for high-pressure hydraulic systems, particularly in sectors such as agriculture, construction, mining, and industrial machinery. In this article, we delve into the significance of OEM EN856 4SP, the manufacturing process, and the essential factors to consider when selecting a supplier.

What is OEM EN856 4SP?

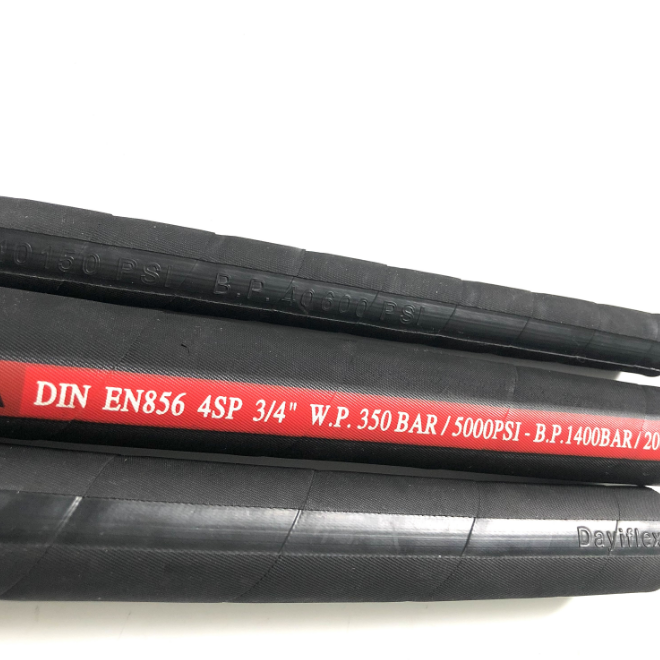

EN856 4SP refers to a specific standard for four-wire spiral hydraulic hoses. These hoses are designed to operate under very high-pressure conditions, making them suitable for heavy-duty applications. The OEM (Original Equipment Manufacturer) aspect implies that these hoses are produced by manufacturers who supply parts and components to other companies that assemble them into their end products.

The design of EN856 4SP hoses incorporates four layers of high-tensile steel wire reinforcement, which provides exceptional strength and flexibility. This feature allows these hoses to withstand extreme pressures, commonly ranging from 420 to 450 bar. The outer cover is typically made from synthetic rubber, which offers excellent resistance to abrasion, weathering, and various environmentally hazardous conditions.

The Manufacturing Process

The production of OEM EN856 4SP hydraulic hoses involves several critical steps

1. Material Selection High-quality rubber compounds and steel wires are selected as these materials directly impact the performance of the hoses. Factors such as heat resistance, oil resistance, and flexibility are critical during this stage.

2. Wire Preparation The steel wires are treated to enhance their strength and resistance to corrosion. They are then wound around a fabric or rubber core in a spiral formation to create multiple layers of reinforcement.

3. Extrusion The inner rubber lining is extruded into a tube shape, which will later constitute the inner wall of the hose. Precision is key at this stage to ensure the internal surface is smooth and free of defects.

4. Assembly The steel wire layers are securely bound to the core, and the outer rubber cover is applied. This assembly process must meet strict tolerances and standards to ensure the hose can withstand its intended pressure ratings.

oem en856 4sp manufacturers

5. Testing Quality control is paramount. Each hose undergoes rigorous testing, including pressure tests, to verify its performance under the specified conditions. Any hose that doesn't meet the criteria is discarded or reworked.

Choosing the Right Manufacturer

When selecting an OEM EN856 4SP manufacturer, several factors need consideration

1. Certification and Standards Ensure that the manufacturer adheres to relevant international standards, including ISO and EN certifications. This ensures that the hoses meet specific performance criteria.

2. Experience and Reputation Look for manufacturers with a long-standing reputation in the industry. Experienced companies are more likely to understand the complexities involved in producing durable and reliable hydraulic hoses.

3. Customization Every application has unique requirements. Choose a manufacturer that can offer customization options in terms of size, length, and connector types.

4. Quality Assurance Investigate the manufacturer's quality control processes. A robust quality assurance mechanism is indicative of a commitment to delivering high-quality products.

5. After-Sales Support Reliable after-sales support is crucial. This ensures that any issues arising post-purchase can be addressed promptly.

Conclusion

The OEM EN856 4SP hydraulic hoses are integral components across various industries, providing the reliability and performance needed in high-pressure applications. Understanding the manufacturing process and choosing the right manufacturer can significantly impact the effectiveness and longevity of these critical components. By focusing on quality and adhering to established standards, businesses can ensure they are equipped with hoses that meet their demanding operational requirements, establishing a foundation of safety and efficiency in their hydraulic systems.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025