335345435

Nov . 16, 2024 21:57 Back to list

oem en 856 4sh hydraulic hose manufacturers

Understanding OEM EN 856 4SH Hydraulic Hose Manufacturers

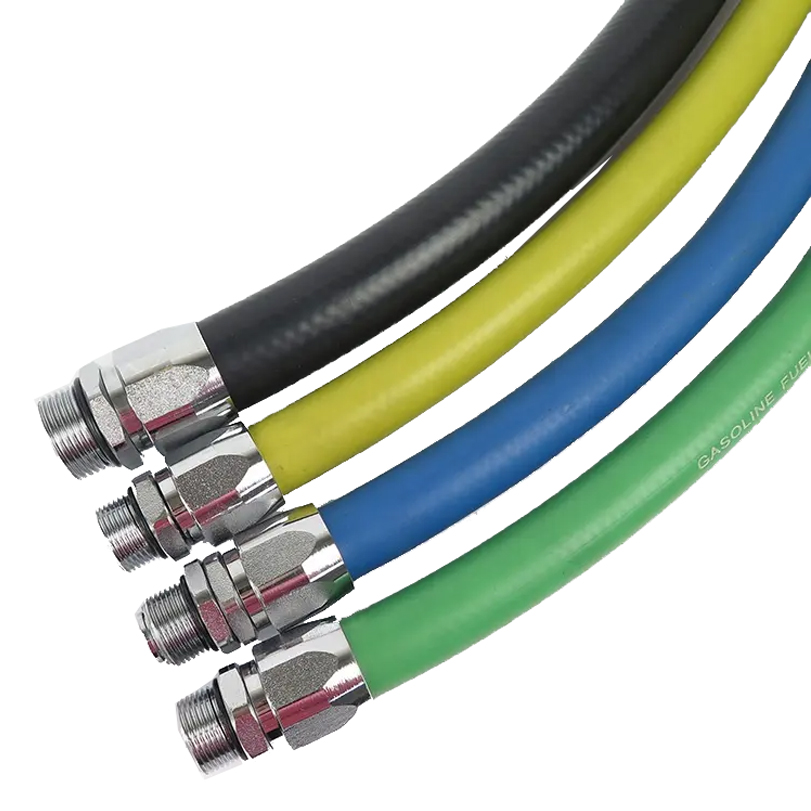

In the ever-evolving world of hydraulic systems, the importance of high-quality hoses cannot be overstated. Among the various standards available, the OEM EN 856 4SH standard has gained significant traction, particularly in heavy-duty applications. This article delves into the intricacies of this standard and the role of manufacturers who specialize in producing hydraulic hoses that meet or exceed these specifications.

What is OEM EN 856 4SH?

The OEM EN 856 4SH is a European standard that specifies the requirements for hydraulic hoses and the corresponding fittings used in high-pressure applications. The 4SH designation indicates that the hose is designed for high-pressure applications, typically up to 400 bar (approximately 5800 psi). This standard ensures that the hoses are robust enough to handle high operating pressures, making them suitable for various industries, including construction, agriculture, and mining.

Hydraulic hoses constructed under this standard are reinforced with steel wire, which provides the needed strength and flexibility. This multi-layered construction helps the hose withstand the rigors of daily use while minimizing the risks of burst or failure, which could lead to catastrophic accidents and significant downtime.

The Role of Manufacturers

Manufacturers play a critical role in ensuring that hydraulic hoses meet the OEM EN 856 4SH standards. The production of high-quality hoses involves several key processes, including the selection of raw materials, design, manufacturing, and rigorous quality control.

The first step for manufacturers is selecting the right materials. The inner tube of the hose must be resilient to various hydraulic fluids, while the outer cover should protect against abrasion, weather conditions, and chemicals. High-grade synthetic rubber and steel wire are commonly used due to their durability and resistance to deformation under high pressure.

oem en 856 4sh hydraulic hose manufacturers

2. Precision Engineering

Manufacturers utilize advanced technology and equipment to produce hoses that meet precise engineering specifications. This includes the use of digital design software for prototyping and simulations to ensure the hose can withstand dynamic pressures and bends. Manufacturers invest in state-of-the-art machinery that can produce hoses with consistent dimensions and qualities.

3. Quality Control

Quality assurance is paramount in hydraulic hose production. Manufacturers are required to implement stringent testing procedures, including hydrostatic tests, impulse tests, and bend tests, to evaluate the performance of the hoses. Compliance with ISO and other international standards is also necessary, ensuring that the products not only meet the EN 856 4SH standard but are also recognized globally for their quality and reliability.

Benefits of Choosing OEM EN 856 4SH Hydraulic Hoses

Opting for OEM EN 856 4SH hydraulic hoses carries several advantages. These hoses are designed to offer superior performance even under extreme conditions. Their high-pressure capacity makes them ideal for demanding environments, reducing the likelihood of failure during operation. Additionally, manufacturers often provide warranties that guarantee the longevity and reliability of their products, offering peace of mind to users.

Moreover, using hoses that comply with these standards can enhance the overall efficiency of hydraulic systems. Their optimal flexibility allows for better routing, which minimizes stress on connection points and reduces the chances of leakage.

Conclusion

As industries continue to rely on hydraulic systems for optimal performance, the need for reliable components such as OEM EN 856 4SH hydraulic hoses becomes increasingly crucial. Manufacturers specializing in these hoses ensure high standards of quality, performance, and safety, ultimately contributing to the efficiency and reliability of hydraulic applications. By understanding the significance of this standard and the role of manufacturers, end-users can make informed choices when selecting hydraulic hoses that meet their specific needs. In the competitive world of hydraulic systems, investing in quality hoses is not just a necessity; it’s a fundamental component of operational success.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025