335345435

Nov . 08, 2024 17:24 Back to list

oem en854 2te factory

Understanding OEM EN854 2TE Factory A Comprehensive Guide

In the ever-evolving world of manufacturing, the term OEM (Original Equipment Manufacturer) plays a crucial role in the production of high-quality goods. When it comes to the rubber and textile industry, EN854 2TE is a designation that represents a specific standard for conveyor belts and hoses. This article delves into the intricacies of OEM EN854 2TE factories, their significance in the industry, and the products they manufacture.

What is EN854 2TE?

EN854 2TE is a European standard that specifies the performance requirements for textile-reinforced hoses used in hydraulic applications. The EN stands for European Norm, indicating that this standard adheres to European manufacturing regulations. The designation 854 indicates that it is part of a series of standards related to hydraulic hoses, while 2TE denotes the construction type and performance class of the hose.

The 2TE classification indicates that the hose features two textile layers, enhancing its strength and flexibility, making it suitable for various hydraulic applications, such as construction machinery, agricultural equipment, and industrial machinery. Hoses that meet this standard are recognized for their durability, high-pressure resistance, and excellent longevity, which are crucial characteristics for any hydraulic system.

The Role of OEM Factories

OEM factories are vital in the production and supply chain of EN854 2TE hoses. These facilities are responsible for designing, manufacturing, and delivering products that meet the specific requirements set forth by clients or brands. In essence, an OEM factory creates products that are then branded and sold by other companies.

One of the primary advantages of working with OEM factories is the ability to customize products to meet particular standards or specifications. This can include adaptations in design, materials, and production processes, allowing clients to offer unique products tailored to their market's demands. For EN854 2TE hoses, companies may seek OEM partners that can ensure compliance with rigorous international standards while also incorporating the latest technological advancements in manufacturing.

Manufacturing Process

The manufacturing process of EN854 2TE hoses in OEM factories involves several critical steps

oem en854 2te factory

1. Material Selection High-quality raw materials are essential for producing durable hoses. The selection process often involves sourcing rubber compounds and textile fabrics that can withstand high pressures and temperatures.

2. Fabrication The selected materials are then cut and layered according to the EN854 2TE specifications. The proper layering is vital to ensure the final product can handle the required pressure levels.

3. Curing The rubber and textile layers are subjected to a curing process, which entails heating them to bond the materials and enhance their strength. This step is crucial in determining the overall durability and longevity of the hoses.

4. Testing Rigorous testing is conducted to ensure that the hoses meet the EN854 2TE standards. This may involve pressure testing, flexibility tests, and checks for any potential defects.

5. Quality Control A quality control team monitors the entire production process to ensure consistency and adherence to specifications, making adjustments as necessary before the products are packaged and shipped.

The Importance of Compliance

Ensuring compliance with EN854 2TE standards is not just about meeting regulations; it is about guaranteeing reliability and safety in hydraulic systems. Hoses that fail to meet these standards can lead to catastrophic failures, resulting in costly downtime and potential hazards for operators. OEM factories that prioritize compliance not only protect their clients' interests but also contribute to a safer working environment across all industries that utilize hydraulic systems.

Conclusion

In summary, OEM EN854 2TE factories play a significant role in the production of hydraulic hoses that adhere to stringent European standards. They contribute to creating high-quality, reliable products that meet the demands of various industries. By understanding the manufacturing processes, compliance requirements, and the advantages of working with OEM factories, businesses can better appreciate the value inherent in utilizing EN854 2TE hoses. As industries continue to evolve and demand higher standards of quality, the importance of partnering with reputable OEM factories will hold even greater significance in ensuring operational efficiency and safety.

-

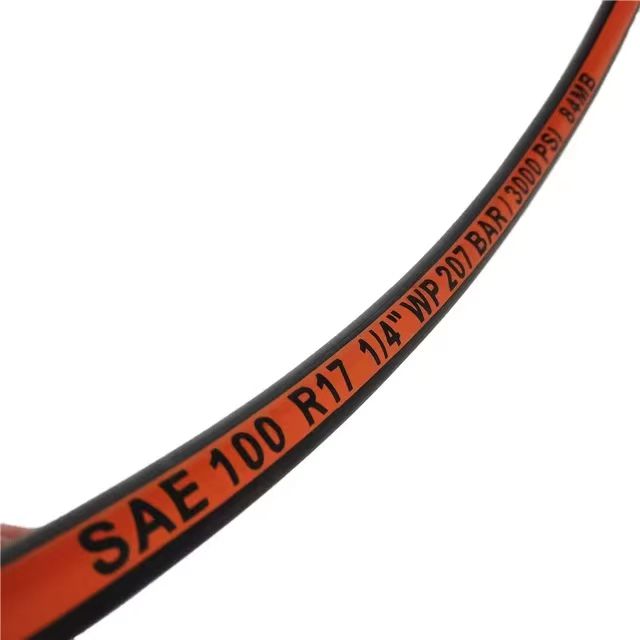

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025