335345435

Oct . 02, 2024 01:44 Back to list

Finding Reliable PTFE Hose Manufacturers for Aeroquip OEM Applications

Understanding OEM Aeroquip PTFE Hose Factories

In the realm of fluid transfer solutions, PTFE (Polytetrafluoroethylene) hoses stand out for their exceptional performance in a variety of demanding applications. Original Equipment Manufacturers (OEMs) often seek out high-quality components to ensure their products meet stringent standards. Among the leading providers of PTFE hoses, Aeroquip has established itself as a reputable name. This article delves into the characteristics and advantages of Aeroquip PTFE hose factories, shedding light on their manufacturing processes, applications, and significance in various industries.

The Importance of PTFE Hoses

PTFE hoses are known for their resistance to chemical corrosion, high temperatures, and extreme pressures. This makes them suitable for a wide range of applications, including aerospace, automotive, food and beverage, pharmaceuticals, and industrial processes. The unique properties of PTFE allow these hoses to perform effectively in environments where conventional materials might fail.

Aeroquip, a brand under the Parker Hannifin Corporation, specializes in the design and manufacture of high-performance hose and fittings

. The company's commitment to quality and innovation has made it a preferred choice for OEMs seeking reliable fluid transfer solutions.Aeroquip's Manufacturing Process

Aeroquip PTFE hoses are produced in factories equipped with state-of-the-art technology that ensures precision and consistency. The manufacturing process begins with the extrusion of PTFE resins, where raw materials are transformed into flexible hose tubes. This process involves several critical steps

1. Material Selection The first step in manufacturing PTFE hoses is selecting the highest-grade materials. This is crucial to achieving the desired durability and chemical resistance. 2. Extrusion The selected PTFE resin is extruded into a tube, where its unique properties are utilized for optimum performance. The extrusion process is meticulously controlled to maintain uniformity in dimensions.

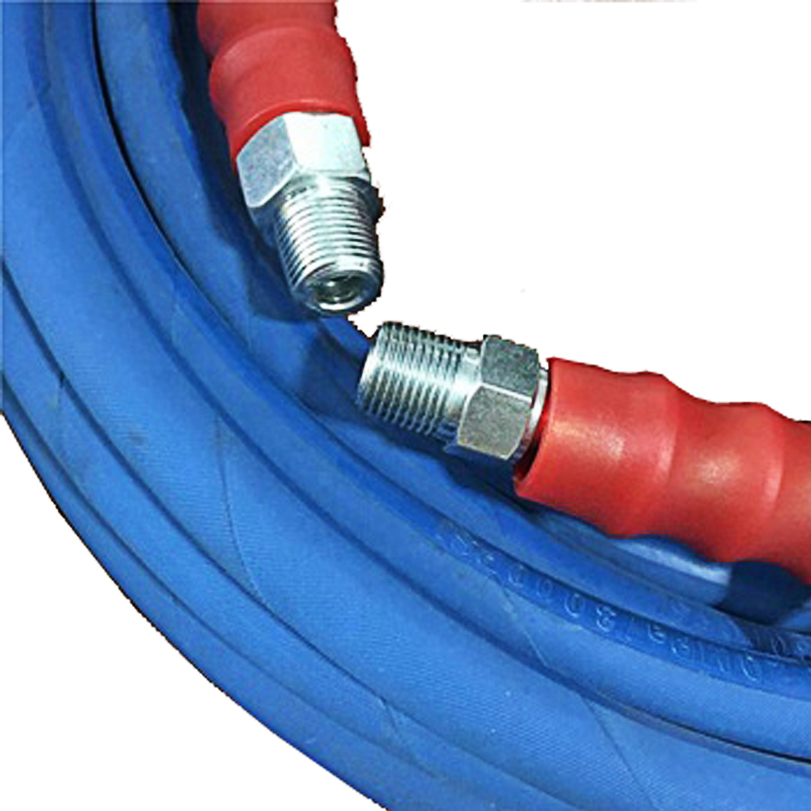

oem aeroquip ptfe hose factories

3. Braiding After the extrusion process, the hoses are subjected to a braiding process for reinforcement. This involves interweaving high-strength materials such as stainless steel or nylon, which enhances the hose's pressure rating and flexibility.

4. Testing and Quality Control Aeroquip places a strong emphasis on quality control. Each hose undergoes rigorous testing to ensure it can withstand extreme conditions. Tests include burst pressure tests, vacuum tests, and leakage tests, ensuring that only the highest quality hoses reach the market.

Applications of Aeroquip PTFE Hoses

The versatility of Aeroquip PTFE hoses makes them suitable for a wide range of applications. In the aerospace industry, these hoses are utilized for hydraulic systems and fuel transfer, thanks to their high integrity and reliability. In the automotive sector, PTFE hoses are used in brake systems and fuel lines, where resistance to high temperatures and chemicals is essential.

Moreover, in the food and beverage industry, PTFE hoses are favored for their non-reactive properties, ensuring that no contaminants leach into the products being transported. Similarly, in pharmaceuticals, where cleanliness and safety are paramount, Aeroquip PTFE hoses play a critical role in manufacturing processes.

Conclusion

In summary, OEM Aeroquip PTFE hose factories are crucial players in the fluid transfer market, delivering reliable and high-quality hose solutions for various industries. Their advanced manufacturing processes, stringent quality control measures, and commitment to innovation make them a leading choice for manufacturers seeking dependable components. As industries continue to evolve and demand more robust solutions, Aeroquip’s PTFE hoses will play an essential role in meeting these challenges, ensuring safe and efficient fluid transfer across multiple applications. For OEMs looking to partner with a proven provider, Aeroquip remains a top contender in the field of PTFE hose manufacturing.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025