335345435

Oct . 19, 2024 01:36 Back to list

oem 4sp hydraulic hose factories

The Evolution and Significance of OEM 204 SP Hydraulic Hose Factories

In the realm of industrial machinery, hydraulic systems play a pivotal role in powering various applications, from construction equipment to agricultural machinery. Among the numerous components that contribute to the efficiency of these systems, hydraulic hoses stand out as critical elements that withstand high pressure and transport fluids effectively. One prominent type is the OEM 204 SP hydraulic hose, which has gained recognition for its reliability and performance. This article will delve into the significance and functionality of OEM 204 SP hydraulic hose factories, spotlighting their role in the industrial landscape.

Understanding the OEM 204 SP Hydraulic Hose

The term OEM stands for Original Equipment Manufacturer, indicating that the hydraulic hose is designed to meet specific standards set by original equipment producers. The 204 SP variant refers to the specifications that define its dimensions, pressure ratings, and environmental adaptability. These hoses are designed to operate under extreme conditions, making them suitable for high-pressure applications in various industries.

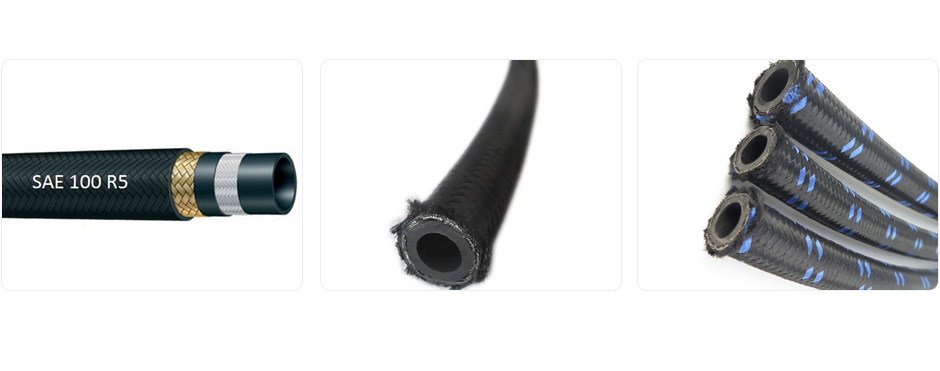

Among the key features of the OEM 204 SP hydraulic hose is its construction, which generally incorporates reinforced rubber layers and braided steel wire. This robust build ensures that the hose can handle the intense pressures often encountered in hydraulic systems. Furthermore, these hoses exhibit excellent resistance to abrasion, thereby increasing their longevity and reliability.

The Role of Factories in Manufacturing OEM 204 SP Hydraulic Hoses

The manufacturing of OEM 204 SP hydraulic hoses involves sophisticated factories that specialize in producing high-quality hydraulic components. These factories employ advanced technology and rigorous quality control processes to ensure that each hose meets the required specifications. The production process typically includes several stages

1. Material Selection High-grade materials are essential for manufacturing durable hydraulic hoses. Factories often source synthetic rubbers, thermoplastics, and reinforcing materials that can endure harsh operational environments.

2. Design and Engineering Engineers work meticulously on the design of the hoses to ensure they meet performance criteria. This includes calculating the necessary specifications for pressure, flexibility, and resistance to environmental factors.

oem 4sp hydraulic hose factories

3. Production Utilizing automated machinery, hoses are manufactured to exacting standards. Processes include extrusion of the rubber layers, braiding the steel reinforcement, and applying the outer layer that provides additional protection.

4. Quality Assurance Before the hoses leave the factory, they undergo stringent testing procedures. This may involve pressure testing, flexibility assessments, and durability tests to ensure they can withstand the stresses of real-world applications.

5. Compliance and Certification Many manufacturers seek certifications from regulatory bodies to validate the quality and safety of their products. This is crucial for OEM components, which must adhere to industry standards.

The Impact on Various Industries

Hydraulic hoses, particularly OEM 204 SP variants, have a far-reaching impact across multiple sectors, including construction, manufacturing, transportation, and agriculture. Their reliability ensures that machinery operates efficiently, reducing downtime and maintenance costs. For instance, in the construction industry, hydraulic hoses are essential for powering excavators, loaders, and cranes, where performance directly influences project timelines and costs.

Moreover, as industries lean toward automation and advanced machinery, the demand for high-quality hydraulic components continues to grow. Factories that specialize in the production of components like the OEM 204 SP hydraulic hose are essential in meeting this demand, driving innovation, and supporting the overall economy.

Future Prospects

As technology advances, the future of OEM 204 SP hydraulic hose factories appears promising. Innovations in materials, design, and manufacturing processes are expected to enhance efficiency and longevity. Additionally, a shift towards sustainable practices in manufacturing could yield eco-friendly alternatives, ensuring that the industry aligns with global sustainability goals.

In conclusion, OEM 204 SP hydraulic hose factories hold significant importance in the industrial sector. By producing reliable hydraulic hoses that meet rigorous standards, these factories not only contribute to the efficiency of various operations but also support the advancement of technology in machinery. As industries evolve and demand grows, the role of these factories will undoubtedly remain crucial to contemporary manufacturing.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025