335345435

Nov . 10, 2024 14:32 Back to list

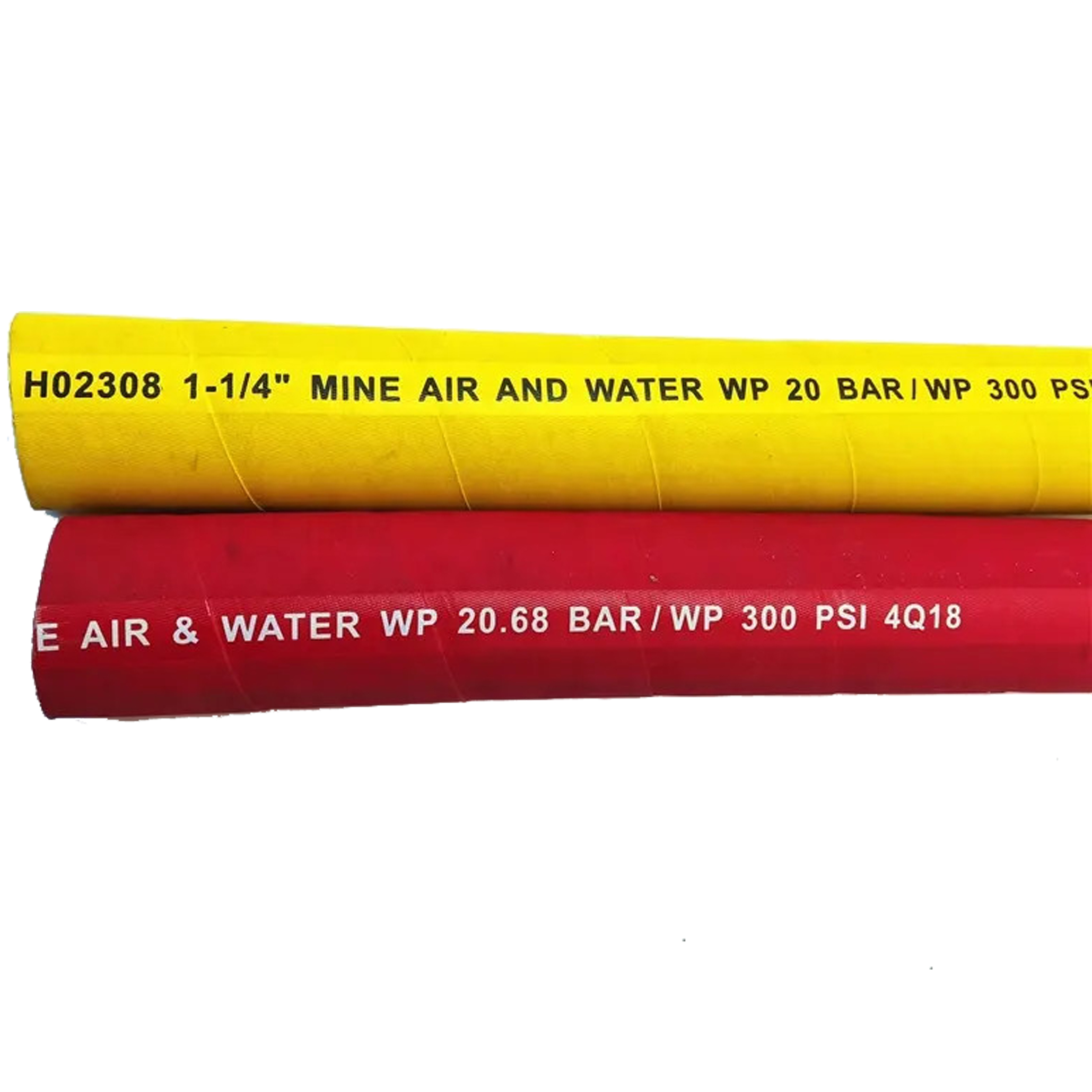

OEM Air Hose Factory for 1/4 and 3/8 Inch Hose Manufacturing Solutions

The Importance of Quality in OEM Air Hose Manufacturing

In the world of industrial equipment and machinery, the importance of high-quality components cannot be overstated. Among these components, air hoses play a crucial role in the functioning of pneumatic systems. Specifically, OEM (Original Equipment Manufacturer) air hoses are essential for ensuring optimal performance and reliability. This article explores the significance of OEM 1/4 and 3/8 air hoses, shedding light on their manufacturing processes and the benefits they bring to various applications.

Understanding OEM Air Hoses

OEM air hoses are designed to meet specific standards set by equipment manufacturers. They are tailored to fit precisely with the machines they are intended for, ensuring that they function seamlessly within the larger system. The dimensions 1/4 and 3/8 refer to the inner diameter of the hoses, which directly impacts air flow and pressure. The choice between these sizes often depends on the application requirements, with 1/4 inch being suitable for lighter tasks and 3/8 inch providing increased flow for more demanding equipment.

Manufacturing Process

The production of OEM air hoses involves several critical stages, each aimed at ensuring the highest quality

.1. Material Selection High-quality rubber or thermoplastic materials are chosen for their durability, flexibility, and resistance to abrasion. The selection process is crucial as it determines the longevity and performance of the hoses.

2. Extrusion and Molding The selected materials are processed through extrusion and molding techniques to create the hose structure. This involves shaping the hose to the desired specifications, ensuring uniformity and consistency throughout the length.

3. Reinforcement Many OEM air hoses feature internal reinforcement, such as textile or steel braiding, to enhance strength and pressure tolerance. This step is vital for applications that require hoses to withstand high pressure without bursting or kinking.

4. Quality Control After manufacturing, the hoses undergo rigorous quality control tests. These tests evaluate the hoses for leaks, pressure resistance, and overall performance. Ensuring that each hose meets stringent quality standards is essential for maintaining reliability in the field.

oem 1/4 3/8 air hose factory

5. Certification Once the hoses pass quality control, they often receive certifications that verify their compliance with industry standards. This certification provides peace of mind to manufacturers and end-users alike.

Benefits of Using OEM Air Hoses

1. Compatibility OEM air hoses are engineered to work perfectly with specific equipment, which eliminates the risk of compatibility issues that can arise with generic alternatives. This ensures efficient operation and reduces downtime.

2. Enhanced Performance With optimal design and construction, OEM hoses can deliver better airflow and pressure, which can significantly improve the overall efficiency of pneumatic systems.

3. Durability The quality materials and manufacturing processes used in OEM air hoses translate to longer life spans. Users benefit from reduced replacement costs and less frequent maintenance.

4. Safety High-quality OEM air hoses are less likely to fail under pressure. This reliability not only safeguards the equipment but also protects the operators, reducing the risk of accidents in the workplace.

5. Customization Many OEM manufacturers offer customization options, allowing businesses to order hoses that meet their unique specifications. This flexibility can enhance operational efficiencies and cater to specialized needs.

Conclusion

In conclusion, OEM 1/4 and 3/8 air hoses are indispensable components in the realm of pneumatic systems. Their tailored design, superior manufacturing processes, and adherence to quality standards make them a preferred choice for businesses seeking reliability and performance. Investing in high-quality OEM air hoses ensures that machinery operates at peak efficiency, ultimately leading to enhanced productivity and safety in the workplace. As industries continue to evolve, the demand for quality components like OEM air hoses will remain paramount, underscoring the critical role they play in modern manufacturing and industrial applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025