335345435

Nov . 15, 2024 08:37 Back to list

oem 1/2 hydraulic hose manufacturers

Understanding OEM 1/2 Hydraulic Hose Manufacturers

When it comes to hydraulic systems, the hoses used are a critical component that ensures the efficiency and safety of the operation. Among the various sizes and types of hydraulic hoses, the 1/2 inch hydraulic hose is noteworthy due to its versatility and common application in several industries. This article explores the role of OEM (Original Equipment Manufacturer) 1/2 hydraulic hose manufacturers and what sets them apart in the manufacturing landscape.

The Importance of Hydraulic Hoses

Hydraulic hoses play a vital role in the transfer of hydraulic fluid in machinery. They are essential for various mechanisms, including construction equipment, agricultural machines, and industrial tools. The capability of a hydraulic system to operate smoothly and effectively is often determined by the quality of the hoses used.

Specifically, 1/2 inch hydraulic hoses are characterized by their ability to handle extensive pressure ranges and flexibility, making them suitable for high-performance machinery. This size is prevalent across various applications, including aerial lifts, forklifts, and other hydraulic equipment.

OEM vs. Aftermarket

When discussing hydraulic hoses, the distinction between OEM manufacturers and aftermarket suppliers is crucial. OEM manufacturers provide parts that are made to match the specific requirements of original machinery manufacturers. As a result, they maintain strict standards in regards to materials and performance.

On the other hand, aftermarket suppliers may offer similar products but are not necessarily held to the same rigorous standards as OEMs. While aftermarket hoses can sometimes be more affordable, they often lack the level of durability and performance associated with OEM products. For businesses that depend on safe and reliable operations, opting for OEM 1/2 hydraulic hoses can be vital.

Quality and Standards

OEM 1/2 hydraulic hose manufacturers adhere to high industry standards. They ensure that their products maintain the necessary specifications for pressure resistance, temperature tolerance, and flexibility. Quality control processes are firmly established, ensuring each hose can withstand the demands of hydraulic systems.

oem 1/2 hydraulic hose manufacturers

In various sectors, including automotive, aerospace, and manufacturing, regulatory compliance is paramount. OEM manufacturers must ensure their hoses meet industry regulations and certifications, providing reassurance for end-users regarding safety and reliability.

Customization and Flexibility

One of the key advantages of working with OEM manufacturers is their ability to provide customized solutions. Hydraulic systems may differ from one application to another, and manufacturers recognize this need for flexibility. OEM 1/2 hydraulic hose manufacturers can design hoses tailored to specific configurations, pressure ratings, and operational needs.

This customized approach not only enhances performance but also extends the life of the hydraulic systems in which these hoses are installed. By working closely with clients, OEM manufacturers can ensure that the hoses meet or exceed expectations in terms of functionality and durability.

The Role of Innovation

As industries evolve, so do the technologies and materials used in hydraulic systems. OEM manufacturers continuously invest in research and development to innovate their product offerings. They explore advancements in material science, which can improve the strength, flexibility, and temperature tolerance of hydraulic hoses.

Additionally, initiatives aimed at enhancing environmental sustainability are also gaining traction. Manufacturers are exploring eco-friendly materials and production methods that minimize waste and energy consumption, paving the way for a greener future in the hydraulic systems industry.

Conclusion

In summary, OEM 1/2 hydraulic hose manufacturers play an integral role in the hydraulic systems sector by providing high-quality, reliable, and customizable hoses tailored to meet industry demands. Their commitment to quality, innovation, and safety ensures that the machinery relying on these hoses operates efficiently and effectively. For businesses prioritizing performance and safety standards in their hydraulic systems, choosing OEM products is often the best path forward. Investing in quality hoses from reputable manufacturers is not just a matter of expense—it’s an investment in the reliability and longevity of critical systems.

-

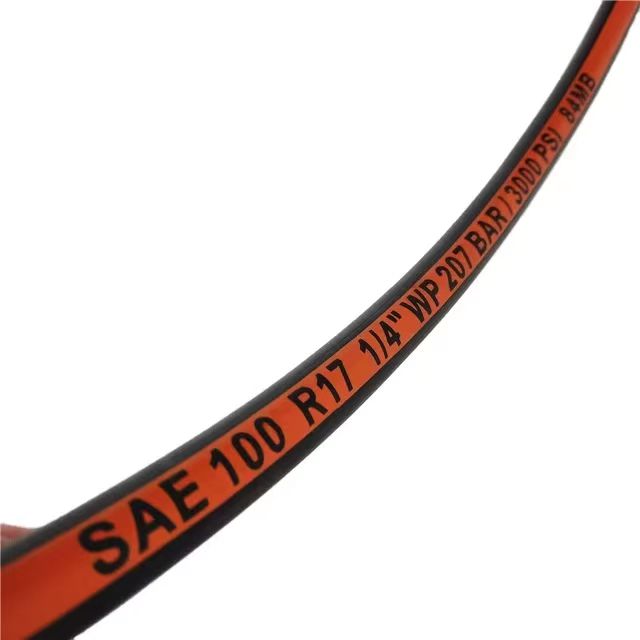

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025