335345435

Aug . 31, 2024 04:03 Back to list

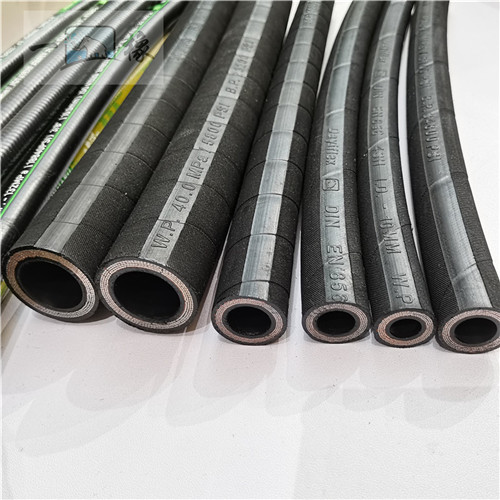

High-Quality OEM Wrapped Cover Hydraulic Hose Manufacturers

The Significance of OEM Wrapped Cover Hydraulic Hose Manufacturers

The hydraulic hose plays a significant role in the functioning of various machines and equipment in different industries. Among various types of hydraulic hoses, those with OEM (Original Equipment Manufacturer) wrapped covers are particularly valued for their durability and performance. This article delves into the importance of OEM wrapped cover hydraulic hose manufacturers, exploring their contributions to various industries and the overall benefits of opting for OEM products.

OEM wrapped cover hydraulic hoses are specifically designed to meet the requirements and standards set by original equipment manufacturers

. These hoses are built to endure high pressure and extreme conditions, making them ideal for applications in construction, agriculture, automotive, and many other industries. Choosing OEM products ensures compatibility, reliability, and optimal performance, which is essential for avoiding costly downtime and repair.One of the key advantages of OEM wrapped cover hydraulic hoses is their robust construction. The wrapped cover provides an extra layer of protection against abrasions, weather, and harsh environments. This is crucial for hoses used in industries where exposure to rough elements is commonplace. By investing in a wrapped cover hose, operators can significantly extend the lifespan of their equipment, reducing the frequency of replacements and repairs.

oem wrapped cover hydraulic hose manufacturers

Moreover, OEM manufacturers often adhere to stringent quality control standards, ensuring that their products meet international safety and performance benchmarks. This commitment to quality not only enhances the functionality of hydraulic systems but also improves safety standards in workplaces. By using OEM products, companies can mitigate risks associated with hydraulic failures, contributing to a safer working environment.

Another notable aspect of OEM wrapped cover hydraulic hose manufacturers is their ability to provide tailored solutions. Different applications require different specifications, and OEM manufacturers understand this need for customization. They often work closely with clients to develop hoses that meet specific requirements, whether it’s a particular size, pressure rating, or resistance to certain chemicals. This collaborative approach fosters innovation and adaptability, essential factors for businesses operating in dynamic markets.

Cost efficiency is another critical point for industries when selecting hydraulic hoses. Although OEM products may appear more expensive initially, the reliability and performance they offer often lead to lower overall costs in the long run. Reducing the frequency of replacements and maintenance, along with ensuring minimal downtime for machinery, can lead to significant savings over time.

In conclusion, OEM wrapped cover hydraulic hose manufacturers play an essential role in various industries, providing superior quality products that ensure operational efficiency and safety. Their commitment to durability, customization, and quality control sets them apart in the market. When selecting hydraulic hoses, investing in OEM products is a strategic decision that can lead to enhanced performance and long-term cost savings. As businesses continue to prioritize reliability and efficiency, OEM manufacturers will remain essential partners in their operational success.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025