335345435

Sep . 17, 2024 04:56 Back to list

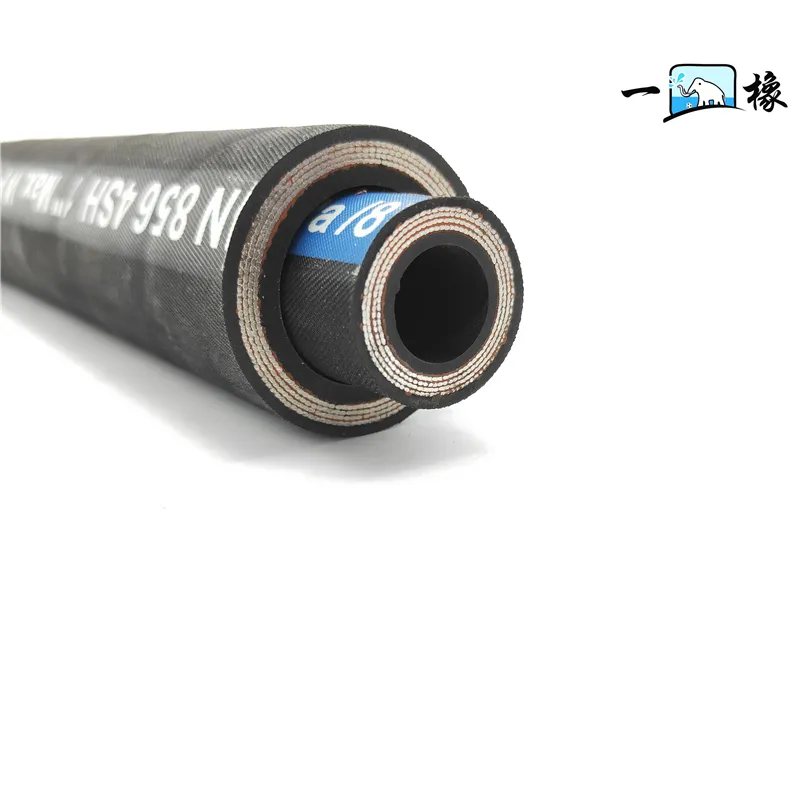

OEM Two Wire Braided Hydraulic Hose

The Importance of OEM Two Wire Braided Hydraulic Hoses in Modern Industrial Applications

In the realm of hydraulic systems, reliability and performance are paramount. One of the key components that ensure these factors is the hydraulic hose. Amongst the various types available, the OEM (Original Equipment Manufacturer) two wire braided hydraulic hose stands out for its durability and versatility. Widely used in various industries, these hoses are essential for safe and efficient machinery operation.

Understanding Two Wire Braided Hydraulic Hoses

Two wire braided hydraulic hoses are designed with two layers of steel wire braiding that wrap around the hose's inner tube. This construction allows the hose to withstand high levels of pressure and environmental stress, making it ideal for heavy-duty applications. The braiding provides exceptional strength and flexibility, enabling the hose to endure bending and flexing without compromising its structural integrity.

Applications Across Industries

The versatility of OEM two wire braided hydraulic hoses makes them suitable for a wide range of applications. In the construction industry, they are commonly used in equipment such as excavators, loaders, and cranes. These hoses facilitate the efficient transfer of hydraulic fluids, which powers equipment for lifting, digging, and moving materials. Similarly, in the agricultural sector, these hoses are vital for tractors and other machinery that require reliable hydraulic systems to operate effectively.

oem two wire braided hydraulic hose

In the manufacturing and automotive industries, two wire braided hoses are used in various machinery, including presses, assembly lines, and automated systems. Their ability to handle high pressures and resist abrasion ensures that machinery operates smoothly, reducing downtime and maintenance costs.

Advantages of OEM Quality

Choosing OEM two wire braided hydraulic hoses ensures that you are getting products that meet stringent manufacturing standards. OEM manufacturers produce hoses that match the specifications of the original equipment, providing compatibility and reliability. This is crucial, as the use of substandard or mismatched hoses can lead to system failures, leaks, and potential safety hazards.

Moreover, OEM hoses are manufactured using high-quality materials, ensuring longevity and resilience even in the most demanding environments. The expert craftsmanship involved in making these hoses guarantees that they can handle fluctuating temperatures and the corrosive nature of hydraulic fluids.

Conclusion

In summary, OEM two wire braided hydraulic hoses play a critical role in the efficiency and safety of hydraulic systems across various industries. Their robust construction, adaptability, and OEM quality make them a preferred choice for engineers and manufacturers alike. As industries continue to advance, the importance of reliable hydraulic hoses will only grow, reinforcing the need for high-quality OEM solutions. Investing in these hoses is not just about meeting regulatory standards; it's about ensuring the operational efficiency and safety of machinery that countless industries rely on. For those involved in the design, maintenance, or operation of hydraulic systems, understanding the value of OEM two wire braided hydraulic hoses can lead to better performance and reliability in their applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025