335345435

Aug . 06, 2024 00:38 Back to list

OEM Suppliers of Four Wire Spiral Hydraulic Hoses for Industrial Applications and Machinery

OEM Four Wire Spiral Hydraulic Hose Suppliers A Vital Component in Modern Industry

In today's fast-paced industrial landscape, the demand for reliable and efficient machinery and equipment is at an all-time high. One crucial component that enhances the performance and durability of hydraulic systems is the four wire spiral hydraulic hose. As industries like construction, agriculture, and manufacturing continue to evolve, the need for high-quality hydraulic hoses has led to the rise of specialized OEM four wire spiral hydraulic hose suppliers.

Understanding Four Wire Spiral Hydraulic Hoses

Four wire spiral hydraulic hoses are designed to withstand high pressure and extreme conditions found in various hydraulic applications. These hoses are constructed with multiple layers of wire reinforcement, providing exceptional strength and flexibility. The four wire spiral design allows for superior pressure handling, making them ideal for applications that demand reliability under heavy loads and challenging environments.

Typical applications for these hoses include

- Construction Equipment Used in excavators, bulldozers, and cranes, where hydraulic systems power critical functions. - Agricultural Machinery Ideal for tractors and harvesters that require robust hydraulic performance. - Manufacturing Machines Essential for various industrial machines that rely on hydraulic systems for operation.

Importance of OEM Suppliers

Original Equipment Manufacturers (OEMs) play a vital role in producing and supplying high-quality four wire spiral hydraulic hoses

. OEM suppliers ensure that their products meet stringent industry standards, offering hoses that not only fit seamlessly into existing systems but also enhance overall performance. Choosing OEM suppliers over generic options can lead to significant advantages1. Quality Assurance OEM suppliers maintain strict quality control processes, ensuring the hoses are durable and reliable. This minimizes the risk of failures and downtime, which can be costly in industrial operations.

2. Customization Many OEM suppliers offer customization options to meet specific application requirements. Clients can work with these suppliers to develop hoses with tailored features, ensuring optimal compatibility and performance.

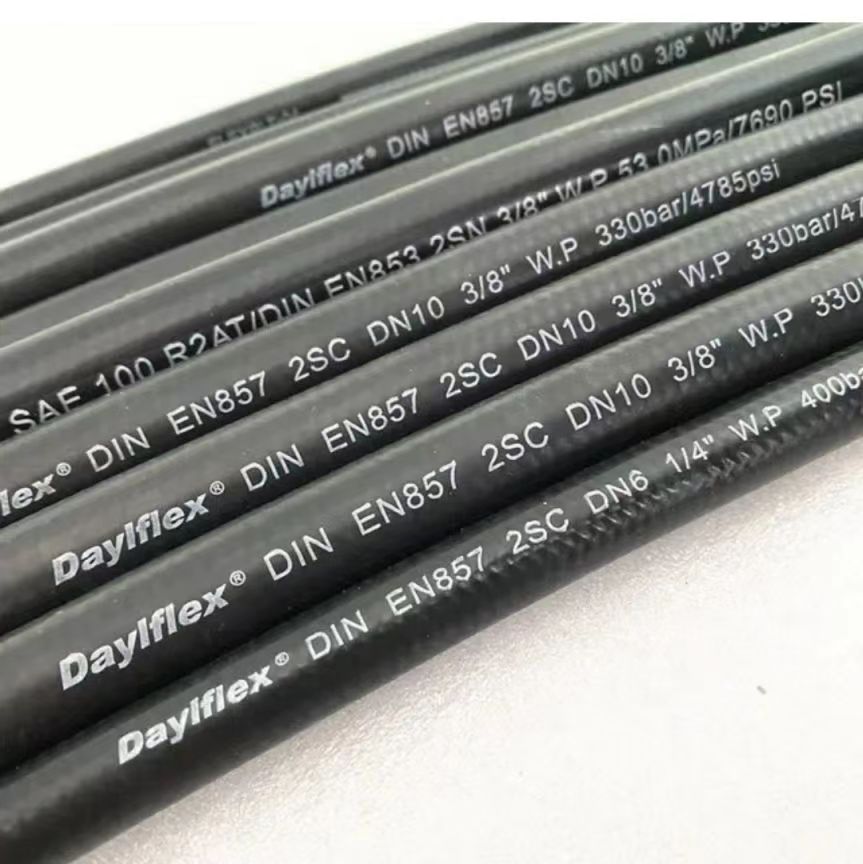

oem four wire spiral hydraulic hose suppliers

3. Technical Support OEM suppliers typically provide valuable technical support, assisting clients in selecting the right hoses for their applications. This expertise can help avoid potential issues and optimize system performance.

Choosing the Right Supplier

When searching for OEM four wire spiral hydraulic hose suppliers, it's essential to consider several factors

- Reputation and Experience Look for suppliers with a proven track record in the industry. Experienced suppliers are more likely to have the knowledge and resources to produce high-quality hoses.

- Product Range A diverse product range indicates that a supplier can cater to various needs, including different sizes, materials, and pressure ratings.

- Certifications Ensure that the supplier adheres to international standards and certifications, such as ISO or SAE, which reflect their commitment to quality and safety.

- Customer Service A responsive and knowledgeable customer service team can greatly enhance the purchasing experience. Good communication ensures that any concerns or questions are addressed promptly.

Conclusion

As industries increasingly rely on hydraulic systems for operational efficiency, the role of OEM four wire spiral hydraulic hose suppliers becomes ever more critical. These suppliers not only provide high-quality products but also contribute to the sustainability and reliability of the hydraulic systems they serve. By partnering with reputable OEM suppliers, businesses can enhance their operational capabilities, reduce downtime, and ultimately achieve greater success in a competitive market. Whether in construction, agriculture, or manufacturing, investing in quality hydraulic hoses is a decision that pays dividends in performance and operational efficiency.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025