335345435

Sep . 05, 2024 01:44 Back to list

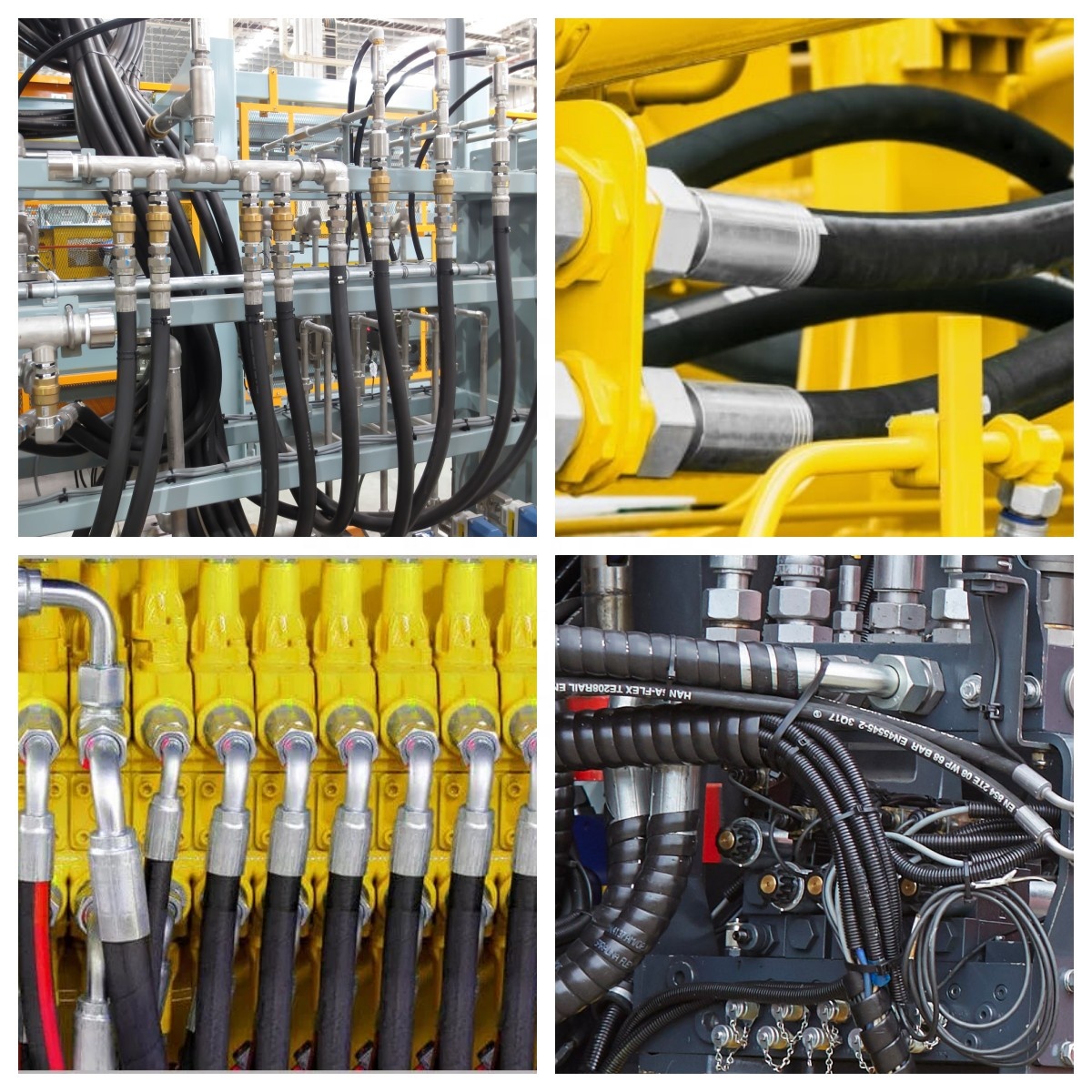

oem hydraulic industrial hose

Understanding OEM Hydraulic Industrial Hoses

In today's rapidly advancing industrial landscape, the demand for reliable and efficient hydraulic systems is rising. One crucial component of these systems is the hydraulic hose, which plays a vital role in the transport of hydraulic fluids to various parts of machinery and equipment. Among the varieties available, OEM (Original Equipment Manufacturer) hydraulic industrial hoses stand out for their quality, compatibility, and performance.

Understanding OEM Hydraulic Industrial Hoses

One of the primary advantages of using OEM hydraulic hoses is their reliability. These hoses are constructed using high-quality materials that can withstand high-pressure environments commonly found in industrial operations. Typically made from reinforced rubber, thermoplastics, or metal, OEM hoses are engineered to resist abrasion, corrosion, and extreme temperatures. This durability not only extends the lifespan of the hoses but also enhances the overall performance of machinery, leading to improved productivity.

oem hydraulic industrial hose

Another significant benefit of OEM hydraulic hoses is compatibility. Since these hoses are designed with specific machinery in mind, they embody the necessary dimensions, pressure ratings, and features needed to integrate seamlessly into the hydraulic systems of industrial equipment. This compatibility is crucial in preventing issues such as improper fittings, which can jeopardize operational efficiency or result in equipment failures.

Moreover, OEM hydraulic hoses are often subject to rigorous testing and certifications, ensuring they meet industry standards and safety regulations. This compliance is vital for businesses in sectors like construction, manufacturing, and agriculture, where safety is paramount. Choosing OEM products reduces the risk of accidents caused by hose failures, thus protecting both employees and equipment.

In addition to quality and safety, businesses can also experience long-term cost savings by opting for OEM hydraulic hoses. While they may come with a higher initial price tag than generic alternatives, the durability and compatibility of OEM hoses often lead to fewer replacements and repairs. Over time, these savings can outweigh any upfront costs, making OEM hoses a wise investment for many industrial applications.

In conclusion, OEM hydraulic industrial hoses are a crucial element in maintaining the efficiency and safety of hydraulic systems. Their tailored design, reliability, and adherence to industry standards make them an excellent choice for businesses seeking to optimize their operations. Investing in OEM hoses not only enhances equipment performance but also fosters long-term savings and safety in industrial settings.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025