335345435

Aug . 14, 2024 05:56 Back to list

OEM Hydraulic Hose Pipe Fittings Manufacturing Plant for High-Quality Custom Solutions and Services

The Significance of OEM Hydraulic Hose Pipe Fittings in Industrial Applications

In the realm of industrial operations, hydraulic systems serve as the backbone for a wide range of machinery and equipment. From construction to manufacturing, the efficiency and effectiveness of these systems largely depend on the quality of the components used—including hydraulic hose pipe fittings. This is where Original Equipment Manufacturer (OEM) hydraulic hose pipe fittings come into play, offering advantages that can significantly impact operational performance.

OEM hydraulic hose pipe fittings are produced by manufacturers that provide components specifically designed for a particular machine or system. This dedicated production ensures that the fittings meet the exact specifications and tolerance levels required for optimal function. Using OEM parts can often lead to enhanced reliability and longevity, which is crucial in industrial settings where downtime can result in substantial financial losses.

The Significance of OEM Hydraulic Hose Pipe Fittings in Industrial Applications

Furthermore, OEM products typically undergo rigorous testing and quality control measures. This ensures that each fitting adheres to industry standards and regulations. For businesses, this can translate into a reduced risk of equipment failure or accidents, fostering a safer working environment. When companies prioritize safety and reliability, they not only protect their workers but also safeguard their investments in expensive machinery.

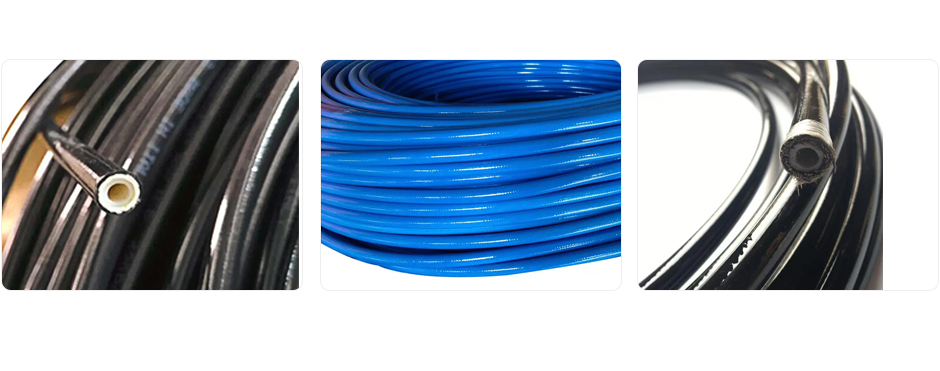

oem hydraulic hose pipe fittings factory

While some may opt for aftermarket or generic fittings due to perceived cost savings, the long-term implications can often be counterproductive. Aftermarket components may lack the same level of quality assurance and may not fit as precisely as OEM parts. This can lead to premature wear and tear, inefficient hydraulic flow, and increased maintenance costs. Ultimately, the decision to invest in OEM hydraulic hose pipe fittings can result in greater overall savings by minimizing repair frequency and operating disruptions.

Besides functionality and safety, OEM hydraulic hose pipe fittings are also essential for maintaining warranties and service agreements. Many equipment manufacturers require the use of original parts to uphold warranty claims. Utilizing generic components can void these agreements, leaving businesses vulnerable to the full financial impact of any needed repairs. For organizations that rely heavily on their equipment, adhering to manufacturer recommendations through OEM parts ensures continued support and protection.

Another significant aspect of OEM hydraulic hose pipe fittings is their adaptability to various industrial sectors. Whether an application is for agriculture, automotive, construction, or manufacturing, there exists a wide range of fittings tailored for specific hydraulic tasks. This versatility allows businesses to find the perfect solutions for their unique requirements, ensuring optimal operational efficiency.

In conclusion, the importance of OEM hydraulic hose pipe fittings cannot be overstated. Their compatibility, quality assurance, and pivotal role in safety make them a wise investment for any industrial operation. As businesses strive for improved performance and decreased downtime, turning to OEM components provides a path toward achieving these goals. For those involved in maintaining or upgrading hydraulic systems, choosing OEM fittings will ultimately contribute to a more reliable and efficient operation, paving the way for sustainable long-term success.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025