335345435

Aug . 13, 2024 09:20 Back to list

OEM High-Pressure Thermoplastic Hose Manufacturer for Durable and Flexible Industrial Solutions.

OEM High Pressure Thermoplastic Hose Factory Revolutionizing Fluid Handling Solutions

In today's industrial landscape, the demand for efficient and reliable fluid handling solutions has never been higher. Among the various options available in the market, thermoplastic hoses have emerged as a superior choice, especially in high-pressure applications. This article explores the importance of OEM (Original Equipment Manufacturer) high-pressure thermoplastic hose factories, their manufacturing processes, benefits, and their role in various industries.

Understanding Thermoplastic Hoses

Thermoplastic hoses are flexible and durable tubes made from synthetic materials. They are designed to transport fluids under high pressure and are known for their lightweight, corrosion-resistant, and abrasion-resistant properties. These hoses can handle a variety of media, ranging from water and oil to aggressive chemicals, making them suitable for diverse applications.

The Importance of OEM Factories

OEM factories play a crucial role in the production of high-quality thermoplastic hoses. These manufacturers specialize in creating hoses that meet specific industry standards and customer requirements. By incorporating the latest technology and innovative manufacturing processes, OEM factories ensure that the hoses produced are not only reliable but also tailored to meet the specific demands of various applications.

One of the key advantages of OEM manufacturers is their ability to customize products. With a deep understanding of industry needs, they can produce hoses with varying diameters, lengths, and pressure ratings. This customization ensures that clients get the right products for their specific systems, enhancing performance and safety across operations.

Manufacturing Process

The manufacturing process of thermoplastic hoses involves several stages, beginning with the selection of high-quality raw materials. The primary materials used include polyurethane, PVC, and nylon, which are known for their excellent mechanical properties. Once the materials are selected, the following steps typically occur

1. Extrusion The raw thermoplastic material is melted and processed through an extrusion machine to form the hose. This step is crucial for ensuring uniform thickness and consistency.

oem high pressure thermoplastic hose factory

2. Reinforcement Many high-pressure hoses require additional reinforcement, which is often achieved through the incorporation of braided or spiraled fibers. This reinforcement allows the hoses to withstand higher pressures and increases their overall durability.

3. Cooling and Finishing After extrusion, the hoses are cooled and undergo finishing processes. This may include cutting to specific lengths, adding fittings, or applying protective coatings.

4. Testing Quality control is paramount in the production of high-pressure thermoplastic hoses. Each batch undergoes rigorous testing for strength, flexibility, and resistance to various chemicals. This ensures that the hoses meet industry standards and customer expectations.

Benefits of Thermoplastic Hoses

The advantages of using high-pressure thermoplastic hoses are numerous

- Lightweight Compared to traditional rubber hoses, thermoplastic options are significantly lighter, making them easier to handle and install. - Chemical Resistance Thermoplastic hoses can resist a broader range of chemicals, enhancing their versatility in various applications.

- Durability With reinforced construction, these hoses can withstand high pressure and harsh conditions, leading to longer service life.

- Flexibility The inherent flexibility of thermoplastic materials allows for easier maneuvering in complex installations.

Conclusion

OEM high-pressure thermoplastic hose factories are at the forefront of providing innovative fluid handling solutions. By leveraging advanced manufacturing techniques and a focus on customization, these factories meet the growing demands of industries such as construction, mining, agriculture, and more. As businesses continue to seek efficient and reliable solutions, the role of OEM manufacturers will undoubtedly expand, driving further advancements in thermoplastic hose technology. Investing in high-quality thermoplastic hoses is not just a choice; it’s a commitment to safety, performance, and reliability in fluid management.

-

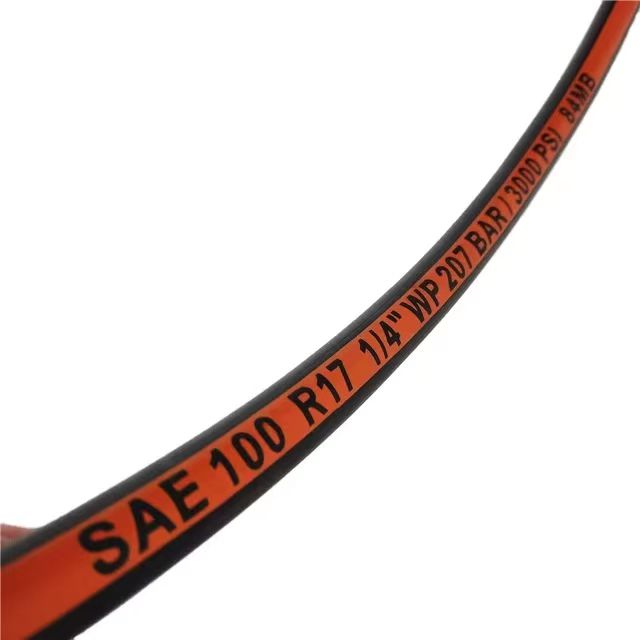

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025