335345435

Sep . 14, 2024 17:55 Back to list

oem high pressure steel wire braided hydraulic hose supplier

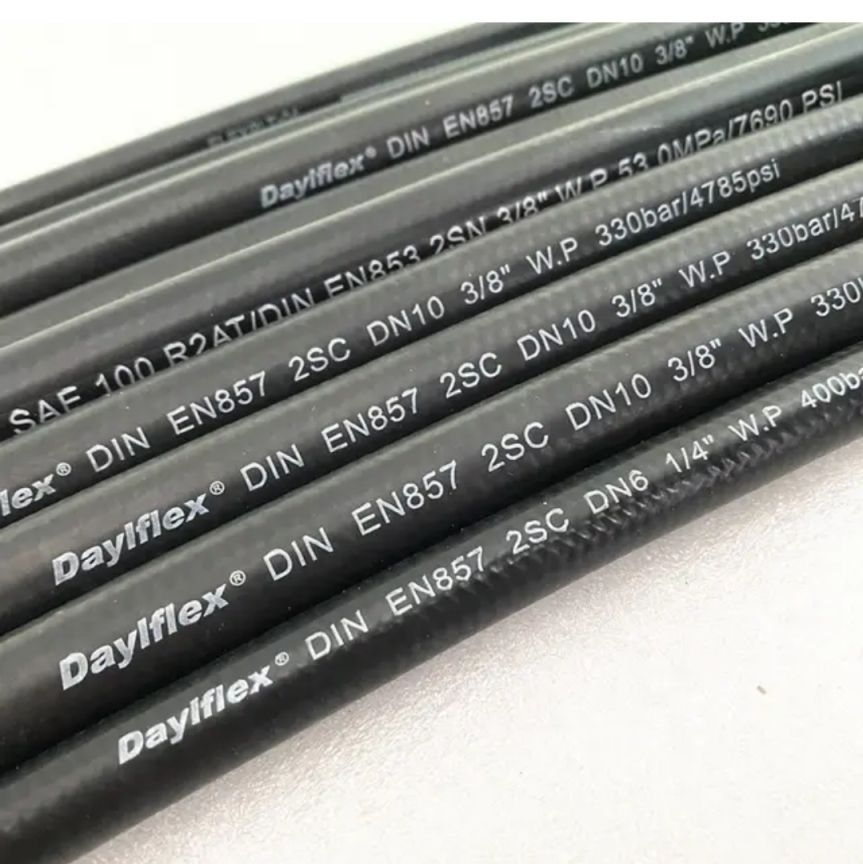

OEM High Pressure Steel Wire Braided Hydraulic Hose Supplier

In the world of industrial applications, the importance of reliable hydraulic hoses cannot be overstated. They play a critical role in the effective transmission of hydraulic power, enabling machinery to function efficiently and safely. One of the most trusted types of hydraulic hoses available today is the high pressure steel wire braided hydraulic hose. This article explores the features, benefits, and considerations when choosing an OEM supplier for these essential components.

What are High Pressure Steel Wire Braided Hydraulic Hoses?

High pressure steel wire braided hydraulic hoses are designed to withstand high pressure applications, making them ideal for use in a variety of industries, including construction, agriculture, and manufacturing. These hoses consist of an inner layer, typically made from synthetic rubber or thermoplastic material, surrounded by a layer of steel wire braiding. This construction provides exceptional strength and durability, allowing the hoses to maintain structural integrity even under extreme conditions.

Key Features

- Pressure Resistance One of the standout features of steel wire braided hoses is their ability to handle high pressures, often up to 4000 PSI or more, depending on the specific design. This makes them suitable for heavy-duty applications where reliability is critical. - Flexibility and Bend Radius Despite their robust construction, these hoses are flexible enough to handle tight bends and complex routing. This flexibility is crucial in applications where space is limited and allows for easier installation.

- Abrasion Resistance The outer layer of these hoses is often designed to resist abrasion, providing added protection against wear and tear from external elements, which is especially important in rugged environments

.Benefits of Choosing an OEM Supplier

oem high pressure steel wire braided hydraulic hose supplier

When seeking high pressure steel wire braided hydraulic hoses, partnering with an Original Equipment Manufacturer (OEM) supplier offers several advantages

1. Quality Assurance OEM suppliers adhere to strict quality control standards, ensuring that the hoses meet industry specifications and safety requirements. This level of reliability is essential for maintaining the efficiency and safety of machinery.

2. Customization Options Many OEM suppliers offer customization services, allowing businesses to specify particular requirements such as length, diameter, and pressure ratings. This personalized approach ensures that the hoses fit perfectly within the intended application.

3. Technical Support Established OEM suppliers typically provide expert technical support and guidance. Their knowledge of hydraulic systems can help businesses optimize their operations and select the right hoses for their specific needs.

4. Long-term Relationships Building a relationship with an OEM supplier often leads to better pricing, improved service, and access to the latest technological advancements in hose manufacturing.

Conclusion

Choosing the right high pressure steel wire braided hydraulic hose and a reliable OEM supplier is crucial for the longevity and safety of hydraulic systems. By understanding the features and benefits of these hoses, as well as the advantages of partnering with an OEM, businesses can make informed decisions that enhance their operational efficiency and reduce downtime. In an industry where safety and performance are paramount, investing in quality hydraulic hoses is a step in the right direction.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025