335345435

Aug . 21, 2024 22:24 Back to list

OEM DIN Hydraulic Hose Fittings Suppliers for Quality Hose Connections and Assemblies

Understanding OEM DIN Hydraulic Hose Fittings Manufacturers

In the modern industrial landscape, hydraulic systems play a crucial role in various applications, including construction machinery, agricultural equipment, and manufacturing processes. Central to the efficiency and reliability of these systems are hydraulic hose fittings, particularly those conforming to the DIN (Deutsches Institut für Normung) standards. As industries increasingly seek dependable and high-performance components, the demand for OEM (Original Equipment Manufacturer) DIN hydraulic hose fittings has surged, prompting a growing number of manufacturers to enter this specialized market.

The Importance of DIN Standards

DIN standards in hydraulic fittings are developed to ensure compatibility and interchangeability across different manufacturers, which is essential for the seamless operation of hydraulic systems. The DIN standard—primarily used in Europe—sets requirements for dimensions, materials, pressure ratings, and testing procedures. By adhering to these standards, manufacturers can produce fittings that ensure safety, enhance performance, and minimize downtime in hydraulic applications.

OEM Manufacturers Reliability and Customization

OEM DIN hydraulic hose fittings manufacturers are pivotal in providing specialized solutions tailored to the unique needs of various industries. Unlike aftermarket components, OEM fittings ensure that each piece is designed and manufactured to meet the original specifications defined by the equipment manufacturers. This means that companies can utilize parts that guarantee compatibility and reliability, critical factors in maintaining the efficiency of hydraulic systems.

Many OEM manufacturers offer a range of customization options to meet specific operational requirements. This customization can include variations in materials, such as brass, stainless steel, or other alloys, as well as different sizes and pressure ratings. The ability to customize fittings means that manufacturers can cater to niche markets, ensuring that specialized equipment functions optimally under varying load and environmental conditions.

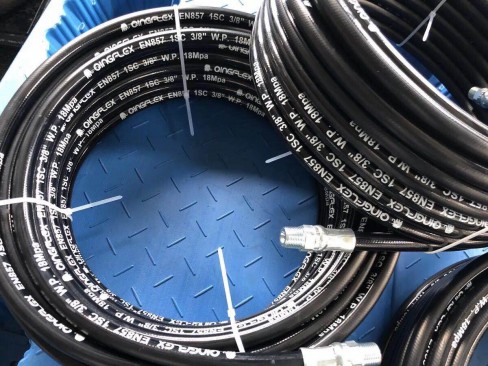

oem din hydraulic hose fittings manufacturers

Manufacturing Processes

The production of OEM DIN hydraulic hose fittings involves several key processes, starting from raw material selection to final testing. High-quality raw materials are sourced to ensure durability and resistance to wear and tear. Advanced manufacturing techniques such as CNC machining, forging, and stamping are employed to create precise fittings that adhere strictly to DIN specifications.

After the manufacturing process, rigorous quality control measures are implemented. Each fitting undergoes extensive testing for pressure tolerance and structural integrity, ensuring that it can withstand the rigors of hydraulic applications. This commitment to quality is what sets OEM manufacturers apart and earns them the trust of their clients.

The Competitive Landscape

The landscape for OEM DIN hydraulic hose fittings is increasingly competitive, with manufacturers striving to innovate while maintaining high standards of quality. Many companies are investing in research and development to create newer, more efficient materials and designs that can handle higher pressures and extreme temperatures. Additionally, the rise of digital technologies and automation in manufacturing processes is helping to improve production efficiency, reduce costs, and ensure consistent quality.

Conclusion

As industries across the globe continue to evolve, the demand for reliable and high-quality hydraulic systems remains a constant. OEM DIN hydraulic hose fittings manufacturers play a vital role in this ecosystem, providing essential components that meet stringent industry standards. By focusing on quality, customization, and innovation, these manufacturers contribute to the safe and efficient operation of hydraulic systems in various applications. As the market grows, so too does the importance of choosing the right manufacturer, one that not only understands the technical requirements but also values the relationship with its clients, ensuring both performance and satisfaction.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025