335345435

Aug . 07, 2024 17:25 Back to list

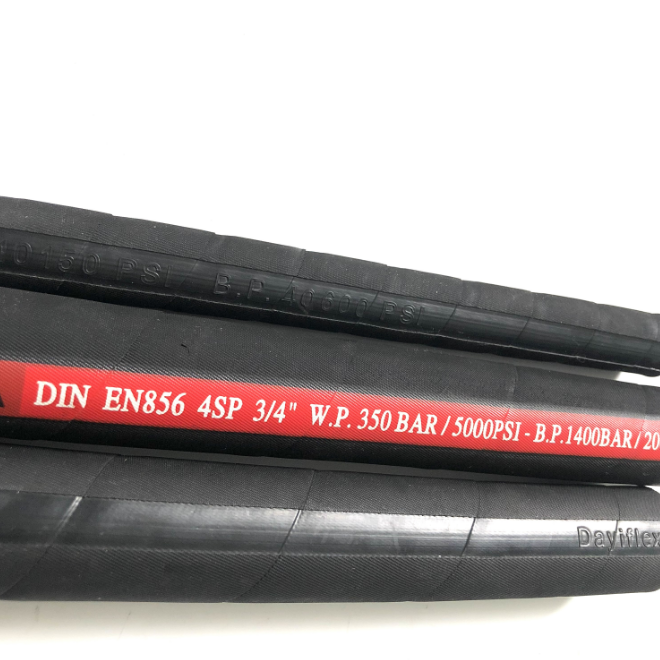

OEM Customized Hydraulic Hose Wrapped Cover Supplier for Enhanced Durability and Performance Solutions

The Importance of OEM Wrapped Cover Hydraulic Hose Suppliers

In the world of industrial and construction equipment, the hydraulic hose plays a critical role in ensuring the efficient functioning of machinery. These hoses are essential for transferring hydraulic fluids, and any disruption can lead to significant downtimes and financial losses. One of the key components in the production of reliable hydraulic hoses is the Original Equipment Manufacturer (OEM) wrapped cover hydraulic hose. This article explores the significance of choosing the right OEM wrapped cover hydraulic hose supplier and how it impacts productivity and safety in various industries.

Understanding OEM Wrapped Cover Hydraulic Hoses

OEM wrapped cover hydraulic hoses are specifically designed to meet the requirements set forth by manufacturers of hydraulic equipment. The wrapped cover is a notable feature that provides an additional layer of protection against abrasion, weather, and other external factors. This durability is crucial in environments where hoses are subjected to extreme temperatures, high pressures, and mechanical wear. The wrapped design not only enhances the hose's longevity but also assures users of optimal performance under strenuous conditions.

Selection of the Right Supplier

When it comes to sourcing hydraulic hoses, the supplier selection process is paramount. An OEM wrapped cover hydraulic hose supplier must demonstrate a commitment to quality, reliability, and customer service. Here are some essential factors to consider

1. Quality Assurance A reputable supplier adheres to strict quality control measures. They should provide hoses that comply with industry standards and certifications, ensuring that the products are safe and effective for use in various applications.

2. Customization Capabilities Different industries have unique needs, which may require customized solutions. A good supplier will offer flexibility in manufacturing so that companies can get hoses tailored to their specific operational requirements.

3. Technical Support Access to technical assistance is vital, especially for companies that may encounter issues during installation or operation. An established supplier should provide expert advice and support to help clients make informed decisions.

oem wrapped cover hydraulic hose supplier

4. Prompt Delivery In the fast-paced industrial environment, waiting for essential parts can lead to significant costs. A reliable supplier should have a robust supply chain management system that ensures timely deliveries and stocking of popular products.

5. Competitive Pricing While quality should never be compromised, it’s essential to find a supplier that offers competitive pricing. This will help businesses manage operational costs without sacrificing the integrity of their equipment.

Benefits of Working with OEM Suppliers

Opting for OEM suppliers for wrapped cover hydraulic hoses brings several advantages

- Consistency in Performance OEM products are designed to work seamlessly with specific machinery, which guarantees better performance and reduces the risk of operational failures.

- Enhanced Safety Quality OEM hoses come with assurance of safe operation, providing peace of mind that machinery will function properly without the risk of leaks or ruptures.

- Long-term Cost Efficiency Though they might be an upfront investment, OEM hoses tend to last longer and require fewer replacements, resulting in long-term savings.

Conclusion

The role of OEM wrapped cover hydraulic hose suppliers in industrial settings cannot be underestimated. By choosing a reliable supplier, companies can ensure that they have access to high-quality, durable hoses that enhance the performance and reliability of their machinery. This not only contributes to operational efficiency but also plays a significant part in maintaining safety standards and reducing long-term costs. Ultimately, the right supplier partnership can empower businesses to thrive in competitive markets, proving that investing in quality can yield substantial returns.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025