335345435

Jul . 27, 2024 19:02 Back to list

OEM Convoluted PTFE Braided Hose Manufacturers and Suppliers for High-Performance Applications

OEM Convoluted PTFE Braided Hose Factories The Backbone of Modern Fluid Transfer Solutions

In the realm of industrial applications, the need for reliable and efficient fluid transfer solutions is paramount. One of the most remarkable innovations in this field is the OEM convoluted PTFE braided hose. These hoses are engineered to meet the rigorous demands of various industries, including aerospace, automotive, chemical processing, and pharmaceuticals. This article will delve into the significance of OEM convoluted PTFE braided hose factories and their contribution to modern manufacturing.

Understanding PTFE Hoses

Polytetrafluoroethylene, or PTFE, is a high-performance plastic known for its exceptional chemical resistance and thermal stability. When hoses are constructed using convoluted PTFE, they offer enhanced flexibility, making them ideal for applications requiring tight bends and considerable movements. The braided exterior provides additional strength and durability, significantly extending the life cycle of the hose compared to conventional options.

The Significance of OEM Manufacturers

Original Equipment Manufacturer (OEM) factories play a crucial role in producing these sophisticated PTFE hoses. They not only ensure that the hoses meet specific industry standards but also customize them according to client specifications. This capability allows various industries to adopt tailored solutions that fit specific operational requirements, further enhancing productivity and reducing downtime.

Quality Assurance

One of the primary advantages of procuring convoluted PTFE braided hoses from OEM factories is the assurance of quality. Such manufacturers adhere to strict quality control processes throughout the production lifecycle. This includes sourcing high-grade materials, employing advanced manufacturing techniques, and conducting thorough testing. As a result, end-users can trust that the hoses will perform reliably under the most demanding operating conditions, minimizing the risk of leakage or failure that could lead to catastrophic outcomes.

oem convoluted ptfe braided hose factories

Diverse Applications

The versatility of PTFE braided hoses can be observed across numerous applications. In the aerospace sector, these hoses are utilized in fuel systems, hydraulic systems, and environmental control systems due to their ability to withstand extreme temperatures and pressures. In the chemical processing industry, PTFE’s resistance to corrosive substances makes it the ideal choice for transporting aggressive chemicals.

Moreover, in the pharmaceutical industry, the non-reactive properties of PTFE ensure the purity of the substances being transferred, which is critical for maintaining safety and efficacy in drug manufacturing. The hygiene standards upheld by OEM manufacturers guarantee that their products are suitable for use in cleanroom environments.

Sustainability and Innovation

As global industries increasingly shift towards sustainable practices, OEM convoluted PTFE braided hose manufacturers are also adopting green manufacturing processes. This includes minimizing waste during production, utilizing recyclable materials, and developing energy-efficient manufacturing techniques. By aligning themselves with sustainable initiatives, these factories contribute positively to the environment while meeting the needs of their clients.

Conclusion

In summary, OEM convoluted PTFE braided hose factories serve as a cornerstone for industries that depend on efficient and reliable fluid transfer solutions. With their expertise in producing high-quality, customized hoses, these manufacturers are pivotal in maintaining safety, functionality, and sustainability across various sectors. As technology continues to evolve and industries demand more sophisticated solutions, the role of these factories will only grow. By investing in advanced manufacturing and innovative practices, OEM manufacturers will remain at the forefront of engineering excellence in the field of fluid transfer solutions.

-

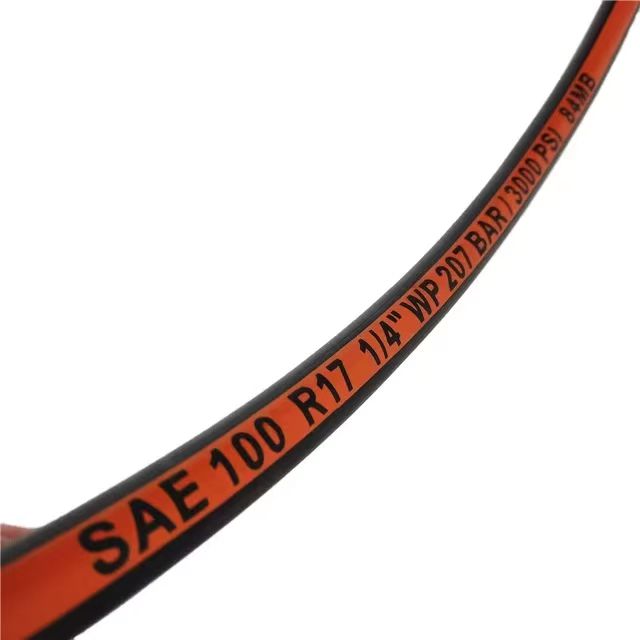

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025