335345435

Aug . 17, 2024 18:41 Back to list

Manufacturer of 1/4 Inch Hydraulic Hoses for Various Industrial Applications

Understanding the Importance of 1/4” Hydraulic Hose in Industrial Applications

In the realm of industrial machinery and equipment, hydraulic hoses play a vital role in ensuring smooth operations. Among the various sizes available, the 1/4” hydraulic hose is a crucial component that has found its use across numerous applications. This article delves into the significance of 1/4” hydraulic hoses, their manufacturing process, and the diverse applications they serve.

What is a Hydraulic Hose?

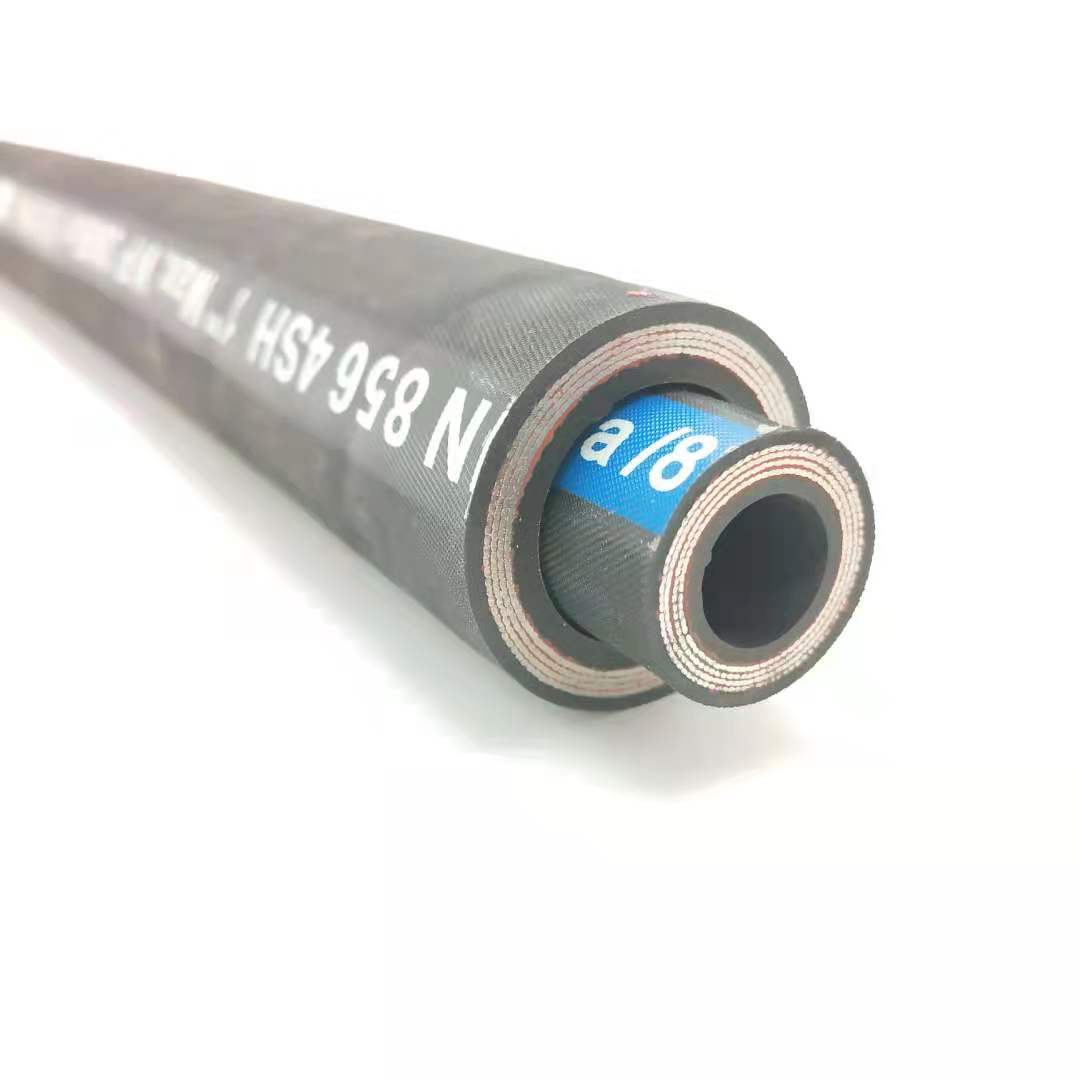

A hydraulic hose is a flexible tube designed to carry fluids under pressure in various hydraulic systems. Typically made from synthetic materials such as rubber or thermoplastic, these hoses are reinforced with braided fibers to withstand high pressures. The 1/4” hydraulic hose, with its nominal inner diameter of 0.25 inches, is a popular size for various industrial applications requiring moderate pressure and flow capacity.

The Manufacturing Process

The manufacturing of a 1/4” hydraulic hose involves several key stages

1. Material Selection High-quality synthetic rubber, often resistant to abrasion, heat, and chemicals, is selected to ensure durability and flexibility. Reinforcement materials, such as steel wires or braided fabric, are also chosen based on the intended pressure ratings.

2. Extrusion The selected rubber material is extruded to form the inner tube of the hose. This process involves melting the raw material and forcing it through a die to create the desired diameter and wall thickness.

3. Reinforcement After the inner tube is formed, layers of reinforcement material are added. This step is critical as it provides strength and resistance to bursting under high-pressure conditions.

4. Covering The outer layer of the hose, which protects the inner components, is applied. This covering is usually designed to be weather-resistant and durable enough to withstand harsh industrial environments.

1/4 in hydraulic hose manufacturer

5. Testing Finally, rigorous testing is conducted to ensure that the hose meets the required standards for pressure, temperature, and fluid compatibility. Each hose must pass these tests to guarantee safety and performance in the field.

Applications of 1/4” Hydraulic Hose

The 1/4” hydraulic hose is versatile and serves a myriad of applications across various sectors

1. Agriculture In farming equipment, these hoses are utilized in hydraulic systems for tractors, harvesters, and other machinery, enabling precision control of agricultural implements.

2. Construction Construction machinery such as excavators, loaders, and dump trucks rely on 1/4” hydraulic hoses for various functions, including lifting, digging, and transporting materials.

3. Automotive Hydraulic systems in cars, especially in braking and lifting mechanisms (like hydraulic lifts), frequently utilize 1/4” hoses due to their compact size and capability to handle high pressures.

4. Manufacturing In plants, these hoses facilitate the operation of machinery used in assembly lines, robotic systems, and material handling, contributing to efficiency and productivity.

5. Marine and Aviation The marine and aviation industries also depend on 1/4” hydraulic hoses for their reliable performance in stabilizing controls and powering essential systems.

Conclusion

The 1/4” hydraulic hose is an indispensable part of modern industrial equipment, facilitating a wide range of functions while ensuring safety and efficiency. As hydraulic systems continue to be integral to the operation of machinery across various sectors, the demand for high-quality hydraulic hoses, specifically the 1/4” size, will only continue to grow. Manufacturers that prioritize quality in their production processes enhance machine performance, reduce downtime, and ultimately contribute to the success of industries worldwide. The importance of these hoses cannot be overstated; they are indeed the lifeblood of hydraulic systems in today's industrial landscape.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025