335345435

Nov . 29, 2024 15:59 Back to list

LPG Hose Manufacturers and Suppliers for Reliable Gas Transportation Solutions

The Importance of Quality LPG Hose Suppliers and Manufacturers

Liquefied Petroleum Gas (LPG) is a crucial energy source used in various applications, from domestic heating and cooking to industrial processes and automobiles. With its widespread consumption, the need for reliable LPG hose suppliers and manufacturers has become increasingly vital. The quality of LPG hoses directly impacts the safety, efficiency, and longevity of LPG applications, making it essential to select the right supplier and manufacturer.

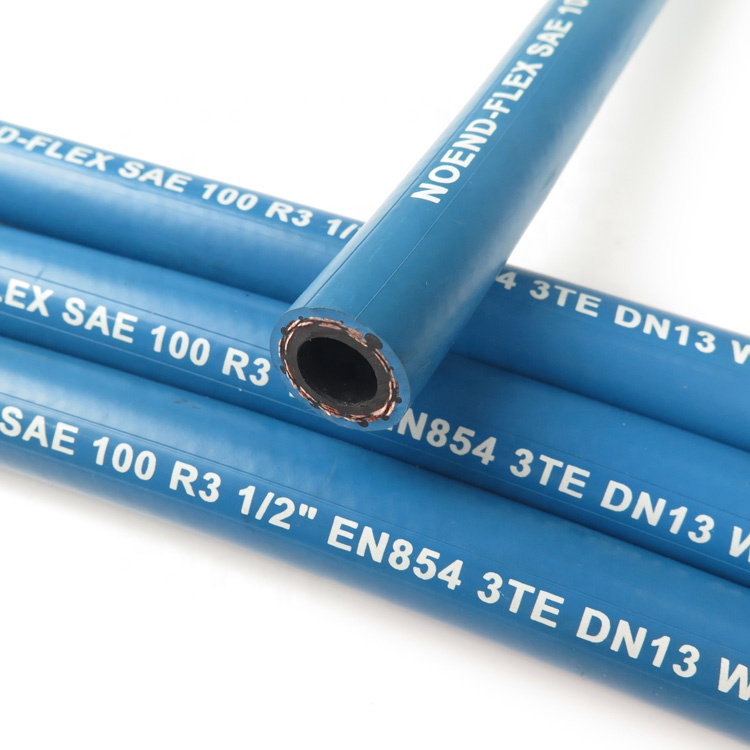

Understanding LPG Hoses

LPG hoses are specialized tubes designed to transport liquefied petroleum gas from storage tanks to various appliances. These hoses must be constructed from materials that can withstand high pressures and temperatures, as well as resist the corrosive nature of gases. High-quality LPG hoses are typically made from rubber or polymer materials reinforced with steel or textile to enhance durability and prevent leaks.

The Role of Suppliers and Manufacturers

Suppliers and manufacturers of LPG hoses play a pivotal role in ensuring the availability and safety of LPG systems. A reputable manufacturer is responsible for producing hoses that meet international safety standards and regulations, such as those set by the American Society for Testing and Materials (ASTM) and the National Fire Protection Association (NFPA). Additionally, suppliers must maintain a robust inventory of hoses and related accessories to meet the demands of various industries.

Selecting the Right LPG Hose Supplier

When choosing a supplier, several factors should be considered to ensure the best quality and service.

1. Certification and Compliance Look for suppliers whose products comply with local and international standards. Certifications from recognized organizations indicate a commitment to quality and safety.

2. Product Range A good supplier should offer a wide range of LPG hoses suitable for various applications. This range should include hoses of different diameters, lengths, and pressure ratings to accommodate specific needs.

3. Quality Assurance Evaluate the quality assurance processes in place. Suppliers should conduct regular testing of their products to ensure they meet safety and performance standards.

lpg hose suppliers manufacturers

4. Reputation and Reviews Research the supplier's reputation in the industry. Customer reviews and testimonials can provide insights into their reliability, product quality, and customer service.

5. After-Sales Support Good after-sales support is crucial for any supplier. Ensure that they provide assistance and technical support in case of any issues with the hoses.

The Advantages of Sourcing from Established Manufacturers

Working directly with established LPG hose manufacturers can offer several advantages

- Customization Reputable manufacturers can provide customized solutions tailored to specific requirements. Whether it's unique sizes, materials, or pressure ratings, direct communication with manufacturers can lead to better-tailored products.

- Cost-Effectiveness Buying directly from manufacturers often eliminates middlemen, potentially reducing costs. This can be particularly beneficial for large-scale projects where bulk purchases are involved.

- Innovation Established manufacturers are more likely to invest in research and development to innovate their products. They might offer the latest technology in hose manufacturing, improving safety and efficiency.

- Expertise Direct access to manufacturer expertise can provide valuable insights into the best practices for hose usage and maintenance, ensuring long-lasting performance.

Conclusion

In conclusion, the significance of quality LPG hose suppliers and manufacturers cannot be overstated. Their role is critical in maintaining the safety and efficiency of LPG systems. When selecting a supplier or manufacturer, it is essential to consider factors such as compliance with safety standards, product range, quality assurance, and reputation. By investing in high-quality LPG hoses from reliable sources, businesses and homeowners can ensure safe and effective use of liquefied petroleum gas in their daily operations. Ultimately, making informed decisions will not only enhance operational efficiency but also contribute to a safer environment for all.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025