335345435

Oct . 17, 2024 12:52 Back to list

lpg gas hose

The Importance of LPG Gas Hoses Safety, Maintenance, and Applications

Liquefied Petroleum Gas (LPG) is a widely used energy source for both residential and industrial applications. LPG is valued for its efficiency, versatility, and relatively clean-burning properties, making it an ideal choice for cooking, heating, and powering vehicles, among other uses. However, the safety and effectiveness of LPG depend significantly on the quality and condition of its associated components, particularly LPG gas hoses.

Understanding LPG Gas Hoses

LPG gas hoses are specialized tubes designed to transport LPG from storage tanks or cylinders to appliances such as stoves, heaters, and grills. These hoses are manufactured from materials that can withstand high pressures and resist the corrosive nature of LPG. Typically made from durable compounds such as rubber or thermoplastic, LPG hoses are engineered to handle temperatures ranging from extreme cold to high heat without degrading.

Safety Considerations

Safety is paramount when handling LPG, as it is a flammable substance that, if leaked, can lead to hazardous situations. Ensuring the integrity of LPG gas hoses is a critical aspect of safety management. Hoses must be inspected regularly for signs of wear and tear, such as cracks, bulges, or kinks. Any visible damage could lead to leaks, which pose serious risks of fire or explosion.

For added safety, LPG hoses are often equipped with safety features such as flame-resistant materials and leak detection technologies. It is also important to use hoses that comply with local regulations and standards, ensuring that they are tested for safety and performance.

Maintenance and Replacement

lpg gas hose

Routine maintenance is essential for maximizing the lifespan and performance of LPG gas hoses. Users should regularly check connection points for tightness, ensuring there are no loose fittings that could result in leaks. Cleaning the hose periodically and protecting it from harsh environmental conditions, like excessive sunlight, can further enhance its durability.

Replacement is inevitable over time, and knowing when to change an LPG hose is crucial. Generally, if a hose has been in use for more than five years, it is advisable to replace it, even if it appears to be in good condition. Regularly replacing hoses, particularly in high-usage environments, can prevent unexpected failures and ensure optimal safety.

Applications of LPG Gas Hoses

LPG gas hoses serve a wide range of applications across various sectors. In residential settings, they are primarily used for connecting gas appliances, while in the commercial sector, they are employed in restaurants for cooking equipment. Moreover, LPG fuels vehicles and machinery in agriculture and construction, necessitating robust and reliable hose connections.

Choosing the right LPG hose for a specific application is essential. Factors such as the operating pressure, temperature range, and flexibility are critical in ensuring proper function. For example, some hoses are designed for high-pressure applications, while others may be more suited for lower pressure scenarios.

Conclusion

In summary, LPG gas hoses are vital components in ensuring the safe and efficient use of liquefied petroleum gas. Their importance in various applications cannot be overstated, as they allow for the safe transportation of LPG to where it is needed most. By following proper safety and maintenance guidelines, users can minimize risks and prolong the life of their hoses. Regular inspections, timely replacements, and the use of compliant hoses ensure that LPG usage remains safe, efficient, and environmentally friendly. Ultimately, understanding the significance of LPG gas hoses contributes to overall safety and efficiency in both residential and industrial contexts.

-

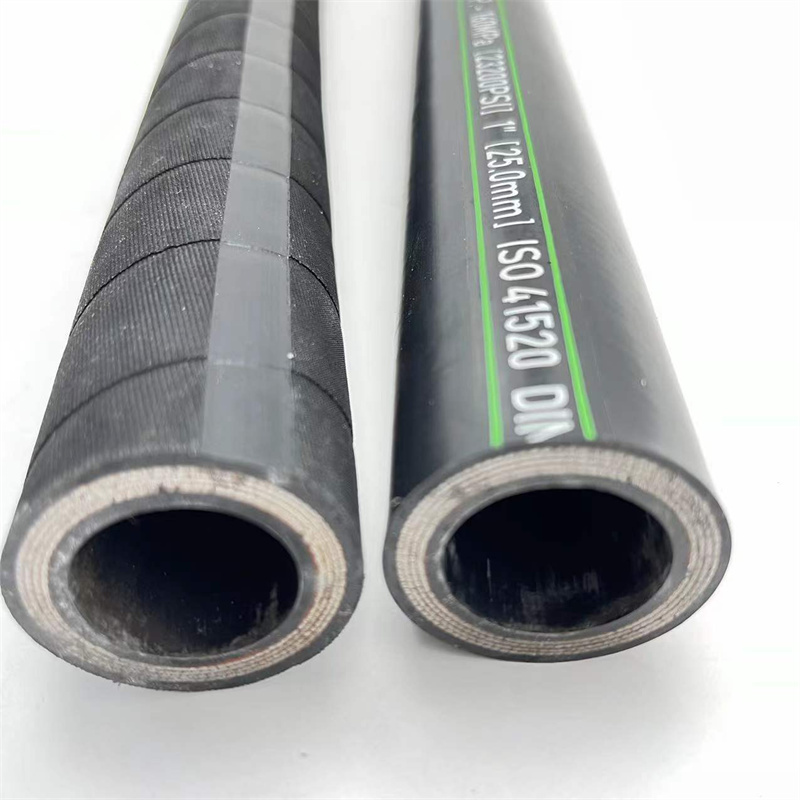

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025