335345435

Oct . 16, 2024 08:41 Back to list

hydraulic hose with male fittings manufacturers

The Importance of Quality Hydraulic Hoses with Male Fittings A Comprehensive Overview

Hydraulic systems are integral to various industries, including construction, agriculture, manufacturing, and more. At the heart of these systems are hydraulic hoses, which play a crucial role in transferring fluids under pressure. One specific type, hydraulic hoses with male fittings, is particularly important in ensuring secure connections and efficient fluid transfer. This article explores the significance of these hoses, the manufacturers who produce them, and the factors to consider when selecting a high-quality product.

Understanding Hydraulic Hoses with Male Fittings

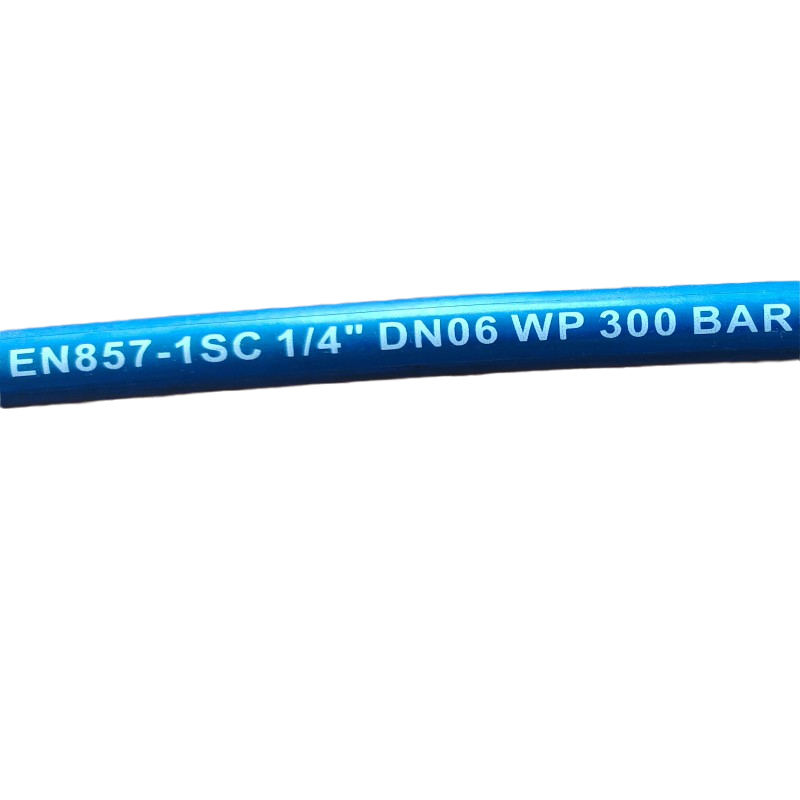

Hydraulic hoses are flexible tubes designed to carry hydraulic fluids from one part of a system to another. Male fittings are connectors that feature external threads, allowing them to connect with female fittings. This type of hose is commonly used in applications where a secure connection is essential to prevent leaks and maintain system integrity. The combination of high-quality hoses and compatible fittings ensures optimal performance of hydraulic machinery.

Manufacturers and Their Role

The market is filled with numerous manufacturers that specialize in producing hydraulic hoses with male fittings. These manufacturers invest in advanced technology and high-grade materials to create products that meet stringent industrial standards. Many of them adhere to international certifications such as ISO 9001, ensuring that their products are reliable and safe.

Reputable manufacturers also focus on innovation, developing hoses that can withstand extreme temperatures, pressures, and various chemical exposures. They provide a range of sizes and configurations, catering to the diverse needs of their clients. It's crucial to partner with a trustworthy manufacturer to ensure the longevity and efficiency of hydraulic systems.

Key Considerations for Selection

hydraulic hose with male fittings manufacturers

When selecting hydraulic hoses with male fittings, there are several factors to keep in mind

1. Material Quality The choice of material affects the hose's durability, flexibility, and resistance to abrasions and oils. Common materials include synthetic rubber, thermoplastic, and stainless steel.

2. Pressure Rating It's essential to know the maximum pressure your hydraulic system will operate under. Hoses should be rated for at least this pressure to ensure safety and reliability.

3. Temperature Range Different hydraulic fluids operate at varying temperatures. Ensure that the hose can handle the expected temperature extremes without degrading.

4. Size and Compatibility Choose hoses and fittings that are compatible in terms of size and threading. Mismatched components can lead to leaks or failures that could compromise the entire system.

5. Certifications Look for products that adhere to industry standards and certifications, which assure quality and safety.

Conclusion

Hydraulic hoses with male fittings are a vital component in many industrial applications. Their ability to effectively transfer hydraulic fluids hinges on the quality of the hoses and the precision of the fittings. By partnering with reputable manufacturers and considering key factors during selection, businesses can ensure their hydraulic systems operate smoothly and efficiently. Investing in high-quality hydraulic hoses will not only enhance machinery performance but also extend the lifespan of critical equipment, ultimately improving productivity and reducing operational costs.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025