335345435

Nov . 20, 2024 19:08 Back to list

hydraulic hose with male fittings factory

The Importance of Quality Hydraulic Hoses with Male Fittings in Industrial Applications

Hydraulic hoses are essential components in various industrial machinery and applications, playing a crucial role in the efficient transfer of fluids under pressure. Among the various types of hydraulic hoses, those equipped with male fittings are particularly significant due to their versatility and reliability in connecting hose assemblies to different equipment. This article explores the importance of high-quality hydraulic hoses with male fittings and the factors to consider when sourcing them from a factory.

The primary function of hydraulic hoses is to transport hydraulic fluid, which is integral to the operation of machinery such as excavators, backhoes, and agricultural equipment. A hydraulic hose with male fittings connects easily to female fittings on components, providing a secure and leak-proof seal. The reliability of these connections is vital because any failures can lead to costly downtime, fluid leaks, and even hazardous working conditions.

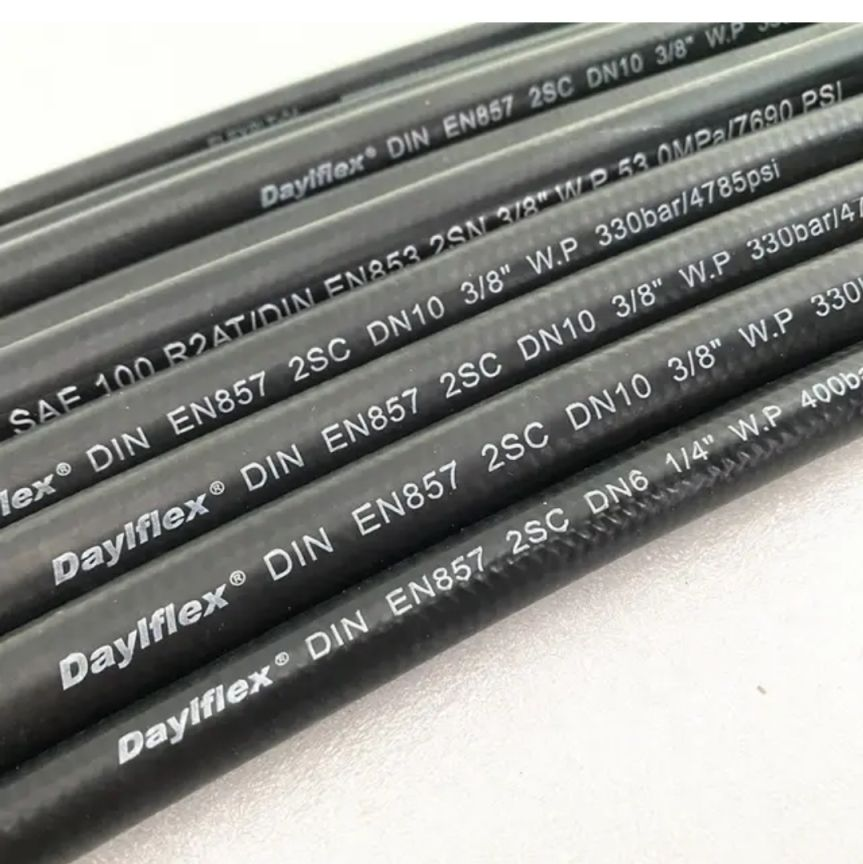

Quality is the foremost consideration when selecting hydraulic hoses with male fittings. A reputable factory specializing in the production of hydraulic hoses will typically adhere to strict industry standards and meet relevant safety regulations. The materials used in manufacturing these hoses significantly influence their durability and performance. High-grade rubber or thermoplastic materials, combined with reinforced layers, result in hoses that can withstand extreme pressures and temperatures.

One of the critical features to evaluate in hydraulic hoses with male fittings is their pressure rating. Each hose is designed to operate under specific pressure limits, and exceeding these limits can lead to catastrophic failure. Manufacturers often provide detailed specifications regarding the maximum operating pressure and burst pressure, allowing purchasers to select hoses that meet their machinery's operational needs. It's essential to choose hoses that not only fit the pressure requirements but also account for potential pressure surges that may occur in hydraulic systems.

hydraulic hose with male fittings factory

Furthermore, the compatibility of the hose material with the hydraulic fluid being used is another crucial factor. Different hydraulic fluids may have specific properties that can affect the performance and longevity of the hose. When sourcing from a factory, it's important to ensure that the hydraulic hoses are designed to withstand the chemical composition of the fluid, preventing degradation and ensuring optimal performance over time.

In addition to quality and compatibility, the design of male fittings plays a pivotal role in the overall efficiency of hydraulic systems. Male fittings are available in various configurations, including threaded, compression, and swivel types. Selecting the appropriate fitting ensures a snug fit, reducing the likelihood of leaks and enhancing the ease of assembly or disassembly during maintenance.

Sourcing hydraulic hoses with male fittings from a factory also offers the advantage of customization. Many manufacturers can produce hoses tailored to specific measurements, configurations, and requirements, catering to the unique needs of different industries or equipment types. This level of customization can significantly enhance operational efficiency and reduce the risk of assembly-related issues.

In conclusion, high-quality hydraulic hoses with male fittings are indispensable in industrial applications, enabling efficient and safe fluid transfer. When selecting a factory for these hoses, it is essential to prioritize quality, compatibility, pressure ratings, and the design of fittings. Partnering with a reliable manufacturer ensures that you receive product excellence, which translates to enhanced performance and reduced operational risks. As industries continue to evolve and demand higher performance from hydraulic systems, investing in quality components like hydraulic hoses will remain a top priority for operators looking to maintain efficiency and safety in their operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025