335345435

Sep . 22, 2024 16:27 Back to list

hydraulic hose specifications

Understanding Hydraulic Hose Specifications

Hydraulic hoses are critical components in various industrial applications, serving as conduits for fluid transfer under high pressures. The selection of the appropriate hydraulic hose is vital for ensuring safety, efficiency, and longevity in hydraulic systems. To make an informed decision, one must understand the key specifications that define a hydraulic hose.

1. Pressure Rating The pressure rating, typically measured in pounds per square inch (PSI) or bar, indicates the maximum pressure that the hose can withstand without failure. It's crucial to select a hose with a pressure rating higher than the maximum operational pressure of the hydraulic system to prevent catastrophic failures.

2. Temperature Range Hydraulic hoses operate in a variety of environments, and their temperature range is critical. Hoses are rated for specific temperature limits, which can vary from -40°F to over 250°F (-40°C to 121°C). Selecting a hose that can accommodate the operational temperature ensures optimal performance and durability.

3. Hose Construction The construction of a hydraulic hose typically consists of three layers the inner tube, reinforcement, and outer cover. The inner tube is designed to hold the hydraulic fluid; it must be compatible with the type of fluid being used. The reinforcement, which may consist of steel wire or textile, provides strength against high pressures. The outer cover protects against environmental factors like abrasion, UV exposure, and chemicals.

hydraulic hose specifications

4. Inner Diameter (ID) The inner diameter of the hose affects fluid flow. A hose with a larger ID can transport more fluid but may be less flexible and harder to install. Conversely, a smaller ID may restrict flow but offers easier handling in tight spaces. It’s essential to consider the system's flow requirements when determining the appropriate ID.

5. Bend Radius The bend radius is the smallest radius at which the hose can be safely bent without compromising its structural integrity. A smaller bend radius allows for tighter installation in limited spaces, but excessive bending can lead to kinking and potential failure of the hose.

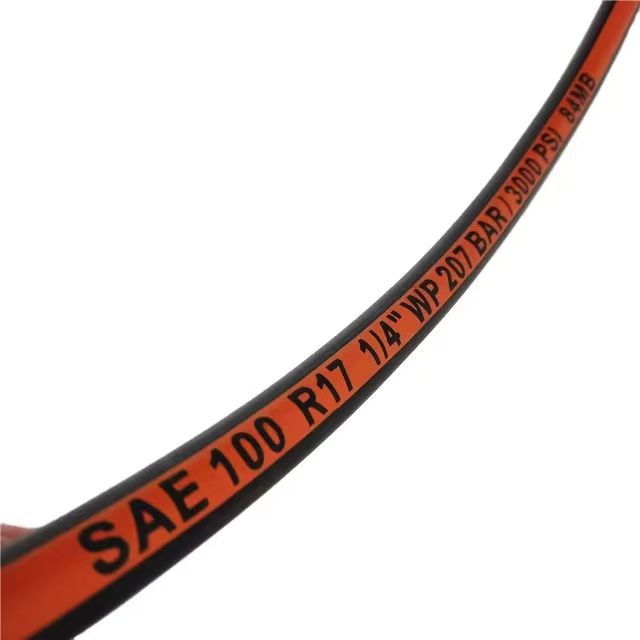

6. Compatibility and Standards Different applications require different material compatibility. Checking for industry standards, such as SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization), ensures that the hose meets safety and performance standards relevant to specific applications.

7. Additional Features Some hoses come with added features like abrasion resistance, flame resistance, or specific couplings. Depending on the environment and application, these features may be crucial for enhancing the hose’s longevity and reliability.

In conclusion, understanding hydraulic hose specifications is essential for selecting the right hose for your application. By considering factors such as pressure rating, temperature range, construction, inner diameter, bend radius, and material compatibility, users can ensure they choose the most suitable hydraulic hose for their needs, thus enhancing safety and performance in their hydraulic systems.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025