335345435

Nov . 19, 2024 16:43 Back to list

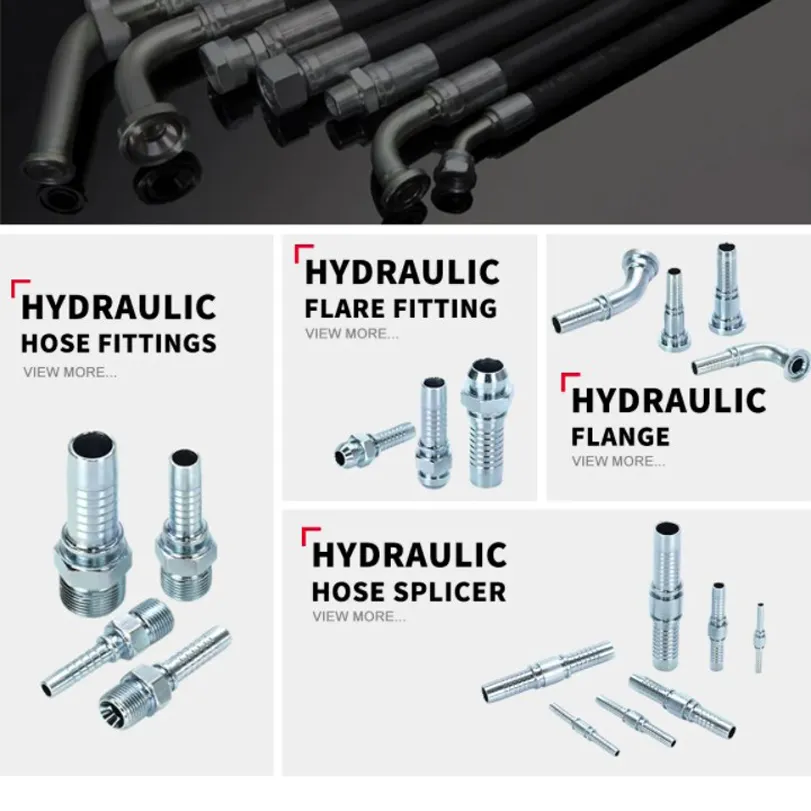

High-Quality Hydraulic Hose and Pipe Fittings Supplier for All Your Needs

The Essential Guide to Hydraulic Hose Pipe Fittings Suppliers

Hydraulic systems are the backbone of many industries, powering everything from construction equipment to agricultural machinery. One of the critical components of these systems is the hydraulic hose, which transports fluid under high pressure. To ensure the optimal performance and safety of hydraulic systems, the selection of the right hydraulic hose pipe fittings is paramount. This is where reputable suppliers come into play.

Understanding Hydraulic Hose Pipe Fittings

Hydraulic hose fittings connect hoses to various components within a hydraulic system, such as pumps and cylinders. These fittings come in numerous sizes, shapes, and materials, designed to accommodate different pressure ratings and fluid types. The fittings must match the specific hose used in a system to prevent leaks or failures, which can lead to costly downtime and safety hazards.

The Role of Suppliers

A reliable hydraulic hose pipe fittings supplier offers more than just products; they provide essential services and expertise

. When selecting a supplier, consider those who offer a comprehensive range of fittings, including crimped, threaded, and quick-release options. Additionally, suppliers should have various sizes and materials, such as stainless steel, brass, or plastic, to meet the specific demands of your application.Moreover, a good supplier understands that the needs of their customers can vary significantly, depending on the industry and application. They should provide tailored solutions, ensuring that the fittings meet the specific requirements of each hydraulic system. This customized approach helps maintain the integrity of the hydraulic system while enhancing performance and longevity.

Quality Assurance

hydraulic hose pipe fittings supplier

Quality is non-negotiable when it comes to hydraulic hose pipe fittings. Suppliers should adhere to rigorous industry standards, such as ISO or SAE specifications, ensuring that their products can withstand the pressures and conditions they will be subjected to in real-world applications. It is advisable to source fittings from suppliers who can provide certifications and compliance documentation for their products. This not only guarantees quality but also gives you peace of mind regarding safety.

Customer Support and Consultation

An ideal supplier should also provide excellent customer support. This includes knowledgeable staff who can assist in selecting the right fittings for specific applications and answering any technical questions you may have. Some suppliers go a step further by offering consultation services, such as on-site assessments of existing hydraulic systems. This support can be invaluable, especially for businesses or individuals new to hydraulic technology.

Supply Chain Reliability

In the fast-paced world of industrial operations, downtime can be costly. Therefore, it’s crucial to partner with a supplier who can deliver products quickly and efficiently. Check the supplier’s inventory management system and their ability to handle bulk orders, as well as their logistics capabilities in terms of shipping and delivery times. A reliable supplier will have a solid supply chain that minimizes the risk of delays, ensuring that you have the parts you need when you need them.

Conclusion

Choosing the right hydraulic hose pipe fittings supplier is a critical decision that can impact the efficiency and safety of your hydraulic systems. By focusing on quality, variety, customer support, and supply chain reliability, you can find a partner that not only meets your current needs but also supports your future growth.

Investing in high-quality hydraulic hose fittings and a dependable supplier will ultimately pay dividends by enhancing the performance and reliability of your hydraulic systems, leading to improved productivity and reduced operational costs. Don’t compromise on your choice; select a supplier that aligns with your specific requirements and industry standards.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025