335345435

Oct . 21, 2024 11:05 Back to list

Hydraulic Hose Fittings Suppliers for High-Quality Industrial Applications and Services

The Role of Hydraulic Hose Pipe Fittings Manufacturers in Industrial Applications

Hydraulic systems are vital for the functioning of various industrial machinery and equipment across a multitude of sectors, including construction, agriculture, manufacturing, and automotive industries. At the core of these hydraulic systems are hydraulic hoses and pipe fittings. The effectiveness, safety, and longevity of these systems heavily depend on the quality of the components used, which is where hydraulic hose pipe fittings manufacturers play a pivotal role.

What Are Hydraulic Hose Pipe Fittings?

Hydraulic hose pipe fittings are crucial components that connect hoses and pipes to different systems within hydraulic machinery. They facilitate the transfer of fluid under pressure, ensuring that energy is efficiently transmitted throughout the system. These fittings come in various shapes and sizes, each specifically designed to cater to particular applications and pressures. Common types of fittings include swivel fittings, straight fittings, elbow fittings, and T-fittings, among others. Each type serves a unique purpose, allowing for flexibility and precise control in hydraulic applications.

Importance of Quality Manufacturing

The performance of a hydraulic system is intricately linked to the quality of the hose fittings used. Poorly manufactured fittings can lead to leaks, bursts, and catastrophic failures, which can not only cause damage to machinery but also pose safety risks to operators. This underscores the importance of sourcing parts from reputable hydraulic hose pipe fittings manufacturers.

Quality manufacturers take several factors into account to ensure the reliability and durability of their products. These include

1. Material Selection The materials used in the production of hydraulic fittings must withstand high pressure and corrosive environments. Manufacturers typically utilize high-grade steel or aluminum, which offers excellent strength-to-weight ratios and resistance to wear and tear.

2. Precision Engineering Hydraulic systems operate under significant pressure; therefore, precise engineering is crucial. High-quality manufacturers utilize advanced machining techniques to ensure that every component meets strict tolerances and specifications.

3. Tight Quality Control Established manufacturers implement stringent quality control processes throughout production. This can involve everything from inspecting raw materials to conducting pressure tests on finished products, ensuring that they adhere to industry standards and regulations.

The Manufacturing Process

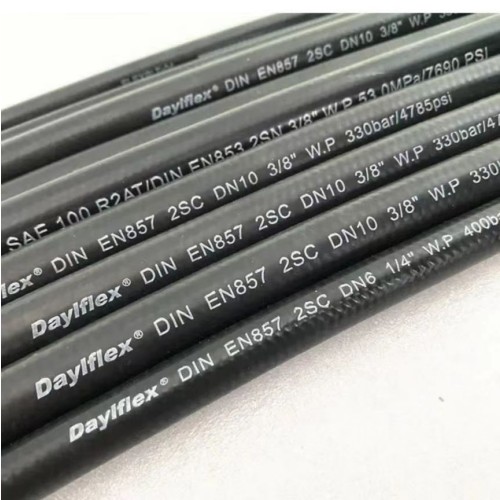

hydraulic hose pipe fittings manufacturers

The manufacturing of hydraulic hose pipe fittings involves several key stages

1. Design and Prototyping The initial phase involves designing fittings based on specified requirements. Advanced software and simulation tools allow manufacturers to create prototypes that can be tested for fit and functionality.

2. Material Procurement Manufacturers source high-quality materials that can withstand the demanding conditions of hydraulic systems. The selection process often includes evaluating suppliers for consistency and adherence to material standards.

3. Machining and Fabrication Using CNC (Computer Numerical Control) machines and other technological equipment, manufacturers shape the materials into the desired fitting configurations. These advanced machines improve precision and efficiency during production.

4. Surface Treatment To enhance corrosion resistance and improve the lifespan of fittings, manufacturers often apply surface treatments such as plating or coating.

5. Testing and Inspection Each batch of fittings undergoes rigorous inspection and testing to ensure they can withstand the pressures they will face in real-world applications. This might include pressure tests, burst tests, and visual inspections for defects.

6. Packaging and Distribution Finally, once the fittings have passed all quality checks, they are packaged carefully for distribution to end-users or retailers.

Conclusion

Hydraulic hose pipe fittings manufacturers serve a fundamental role in the overall functioning of hydraulic systems. Their expertise in designing, engineering, and producing high-quality fittings directly influences the efficiency, safety, and longevity of hydraulic machinery. As industries continue to evolve and demand more complex and robust hydraulic solutions, the role of these manufacturers will remain critical.

For businesses looking to optimize their hydraulic systems, choosing the right fittings from a reputable manufacturer is essential. Investing in quality components not only enhances operational efficiency but also safeguards against the potential hazards associated with hydraulic failures. Thus, the hydraulic hose pipe fittings manufacturers stand as stalwarts of industrial reliability and safety.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025