335345435

Nov . 11, 2024 02:15 Back to list

Top Hydraulic Hose Manufacturers and Their Leading Factories Worldwide

The World of Hydraulic Hose Manufacturers A Closer Look

In today’s industrial landscape, hydraulic hoses play an essential role in the functioning and efficiency of various machinery and equipment. From construction sites to manufacturing plants, these durable tubes are crucial in transmitting hydraulic fluid and enabling heavy equipment to operate smoothly. Consequently, the demand for high-quality hydraulic hoses has led to the emergence and growth of numerous hydraulic hose manufacturers worldwide. This article explores the role of these manufacturers, the significance of their products, and what sets them apart in a competitive industry.

Understanding Hydraulic Hoses

Hydraulic hoses are specially designed tubes that convey pressurized hydraulic fluids. They consist of three main components the inner tube, the reinforcement layer, and the outer cover. Each part serves a specific function, ensuring flexibility, strength, and protection against external elements. Manufacturers typically utilize materials such as synthetic rubber, thermoplastics, and steel wire for reinforcement, depending on the application and pressure requirements.

The applications of hydraulic hoses are diverse, spanning various industries including construction, agriculture, automotive, and manufacturing. For instance, in construction, hydraulic hoses are critical for the operation of excavators, loaders, and cranes, enabling them to lift heavy loads effortlessly. In agricultural machinery, they facilitate the operation of equipment like tractors and harvesters. This wide usage underlines the importance of reliable hydraulic hose manufacturers in supplying safe and effective products.

The Role of Hydraulic Hose Manufacturers

Hydraulic hose manufacturers are key players in the industry, engaging in the design, production, and distribution of hydraulic hoses. Their roles extend beyond simple manufacturing; they also involve rigorous testing and quality assurance processes to ensure that their products meet safety and performance standards. These manufacturers often invest in research and development to innovate and improve their products, enhancing durability and efficiency while reducing costs.

Moreover, many reputable manufacturers offer customized solutions to cater to specific client needs. Customization includes variations in size, material, and temperature resistance, allowing businesses to find the right hoses for their unique applications. This ability to adapt is crucial, as different industries have varying demands and challenges.

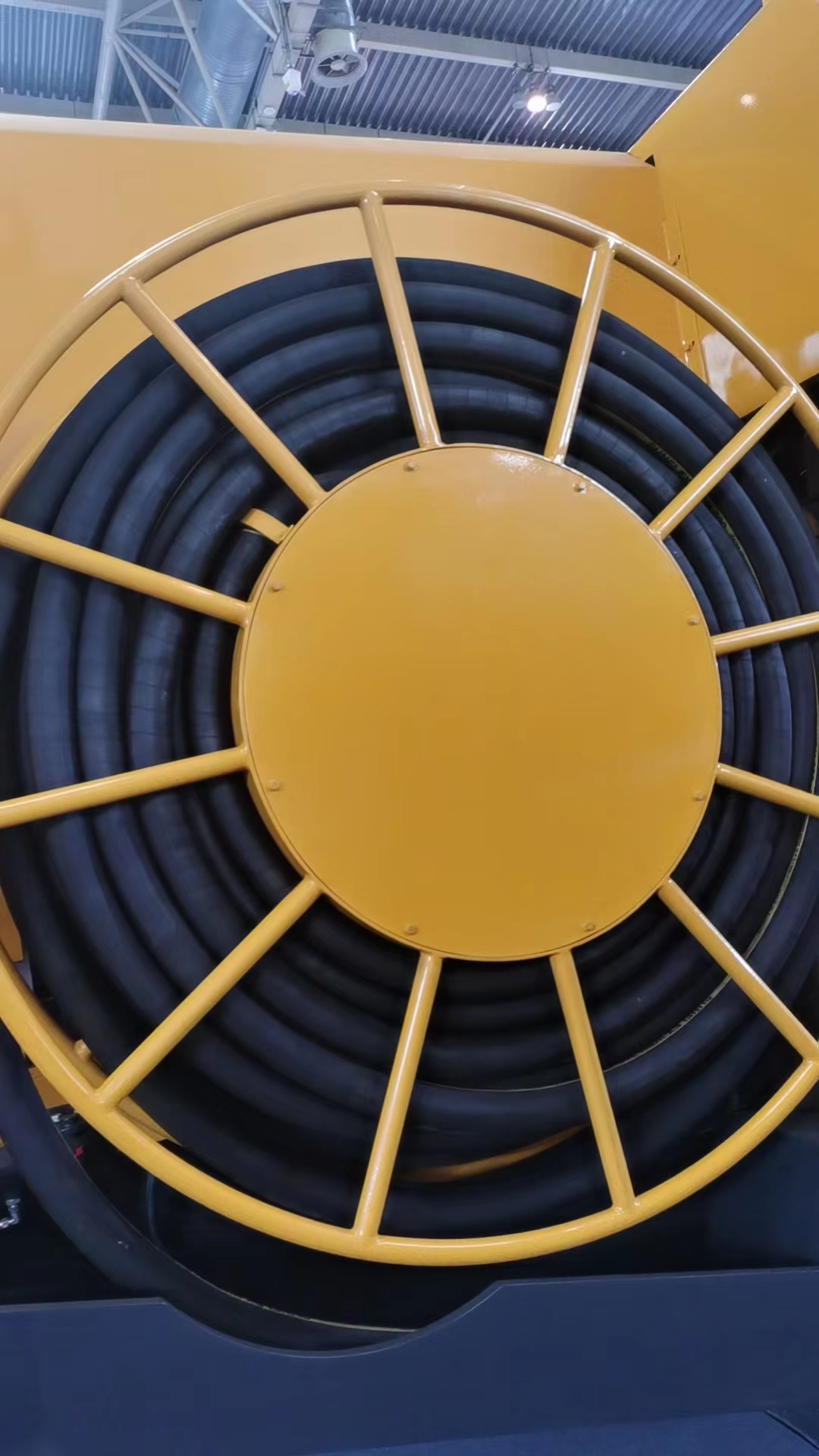

hydraulic hose manufacturers factory

Quality and Standards

The quality of hydraulic hoses is paramount since failures can lead to significant downtime, costly repairs, and even accidents. Thus, credible manufacturers adhere to industry standards such as ISO, SAE, and EN specifications. These standards ensure that hoses can withstand the pressures, temperatures, and environmental conditions they are subjected to, thereby enhancing safety and efficiency.

Additionally, leading manufacturers implement stringent quality control measures throughout their production processes. From the selection of raw materials to the final inspection, every stage is carefully monitored to ensure the highest standards are met. Such diligence helps build trust with clients and reinforces the reputation of the manufacturers.

Challenges and Innovations

The hydraulic hose manufacturing sector faces several challenges, including fluctuating raw material costs, environmental regulations, and increasing competition. To navigate these hurdles, manufacturers are continually innovating. Technologies such as automated production processes and advanced materials are being embraced to improve efficiency and reduce waste.

Sustainability is also becoming a core consideration for many manufacturers. By utilizing eco-friendly materials and implementing greener production practices, they can meet growing consumer demand for environmentally responsible products.

Conclusion

Hydraulic hose manufacturers are indispensable to the functioning of modern industries. Their commitment to quality, innovation, and customer satisfaction drives the sector forward, ensuring that businesses have access to reliable and efficient hydraulic solutions. As technology progresses and market demands evolve, these manufacturers will continue to adapt, playing a vital role in supporting industrial growth and sustainability across the globe.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025