335345435

Sep . 25, 2024 13:09 Back to list

Types of Hydraulic Hose Fittings for Industrial Applications and Their Uses

Understanding Hydraulic Hose Fittings Types in the Industry

Hydraulic hose fittings play a crucial role in the efficiency and safety of hydraulic systems across various industries. These fittings serve as connectors between hoses and other hydraulic components, enabling seamless fluid transfer and maintaining system integrity under high pressure. With numerous types available, selecting the right hydraulic hose fitting is essential for optimal performance and durability.

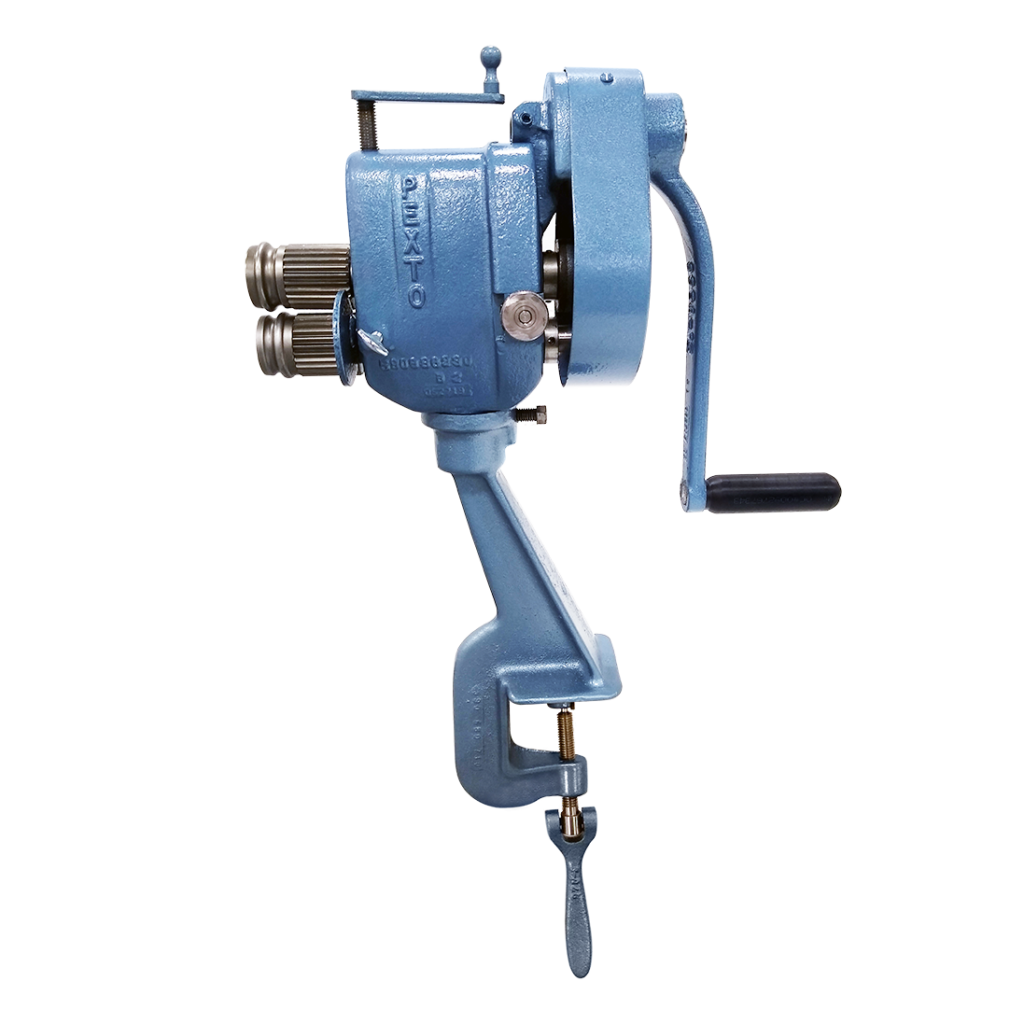

The first category of hydraulic hose fittings is the crimp fittings. These are widely used due to their reliable connection. Crimp fittings are designed to be permanently attached to hoses by using a crimping machine, which compresses the fitting onto the hose. This method ensures a leak-proof seal and is often used in high-pressure applications, making it a popular choice in industries like construction and manufacturing.

Another common type is the swivel fittings. What sets swivel fittings apart is their ability to rotate, which helps prevent hose kinking and twisting. This feature is particularly beneficial in applications where the hose needs to move or bend frequently. Swivel fittings can be found in various configurations, including straight, elbow, and tee shapes, making them versatile for different hydraulic connections.

hydraulic hose fittings types factory

Barbed fittings are also significant within the hydraulic domain. Designed with ridges or barbs, these fittings grip the inside of the hose to secure the connection. They are generally used for lower-pressure applications and are straightforward to install. Barbed fittings can be ideal for industrial environments where quick assembly and disassembly might be necessary.

Threaded fittings form another critical category of hydraulic hose fittings. These include standard male and female thread designs that can be easily screwed together to form a connection. Threaded fittings are versatile, with options for various thread types, such as NPT (National Pipe Thread) and BSP (British Standard Pipe). Their adaptability allows for seamless integration into existing systems, making them suitable for both permanent and temporary installations.

Push-on fittings are gaining popularity due to their ease of use and convenience. These fittings do not require any clamps or special tools, allowing for quick hose changes. They are often used in applications where system maintenance and flexibility are paramount. However, it is essential to ensure that the proper hose type is used with push-on fittings to prevent leaks.

In conclusion, understanding the different types of hydraulic hose fittings is essential for anyone involved in the hydraulic industry. Each fitting type, whether it be crimp, swivel, barbed, threaded, or push-on, offers unique advantages tailored to specific applications. The right choice of fitting promotes efficiency, safety, and longevity of hydraulic systems. As industries evolve and automation increases, staying informed about the latest advancements in hydraulic hose fittings will undoubtedly enhance operational performance and reliability.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025