335345435

Nov . 05, 2024 17:11 Back to list

hydraulic hose fittings

Understanding Hydraulic Hose Fittings A Key Component in Fluid Power Systems

Hydraulic hose fittings are essential components in fluid power systems, responsible for connecting hoses to various hydraulic machinery and equipment. These fittings play a critical role in ensuring the seamless transmission of hydraulic fluid, allowing machines to operate efficiently and effectively. As industries increasingly rely on hydraulic systems for automation and power generation, understanding the different types of hose fittings and their applications becomes vital.

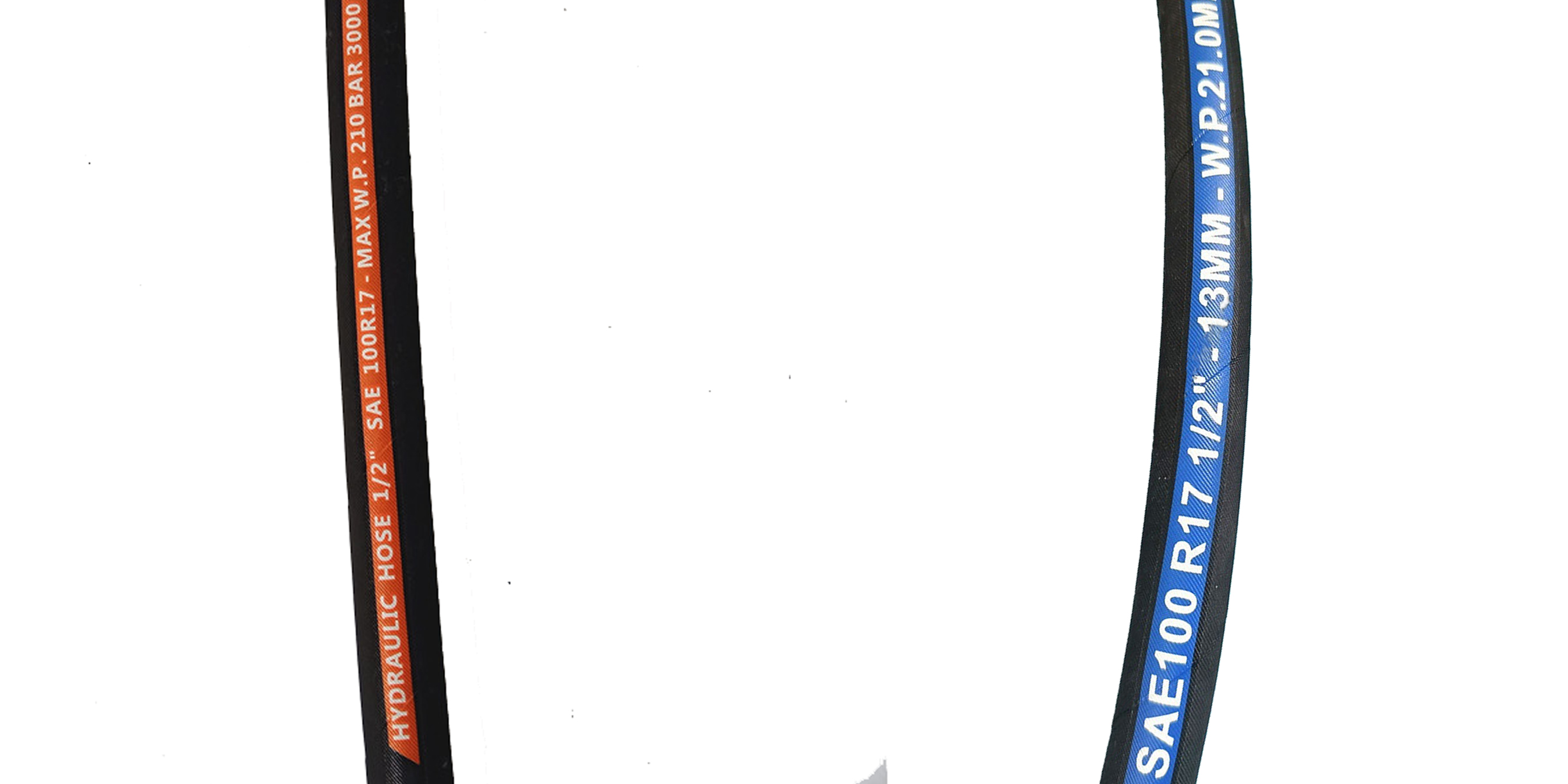

There are several types of hydraulic hose fittings, each designed to serve specific functions and requirements. The most common types include JIC (Joint Industrial Council), NPT (National Pipe Thread), and SAE (Society of Automotive Engineers) fittings. JIC fittings feature a 37-degree flare design that provides a leak-free seal, making them suitable for high-pressure applications. NPT fittings, on the other hand, utilize a tapered thread design that creates a tight seal when connected, often used in lower-pressure installations. SAE fittings are characterized by their flat face and are commonly used in mobile machinery.

When selecting hydraulic hose fittings, compatibility is paramount. It’s crucial to ensure that the fittings match the size and pressure rating of the hose and the hydraulic system in use. Moreover, material selection is another important aspect to consider. Common materials for hydraulic fittings include steel, stainless steel, and aluminum, each offering varying degrees of corrosion resistance and strength depending on the application.

hydraulic hose fittings

Proper installation and maintenance of hydraulic hose fittings are vital to the overall performance of hydraulic systems. Fittings should be installed according to the manufacturer’s specifications to prevent leaks and potential system failures. Regular inspection and maintenance, including checking for wear and tear, ensure that fittings remain in good condition and function correctly over time.

In addition to the technical aspects, safety should always be a priority when working with hydraulic systems. High-pressure hydraulic systems can pose significant risks if not handled properly. Operators must wear appropriate personal protective equipment (PPE) and follow safety protocols to minimize accidents.

In conclusion, hydraulic hose fittings are integral to the functionality and reliability of hydraulic systems across various industries. Understanding their types, applications, and maintenance will not only enhance operational efficiency but also contribute to the safety and longevity of hydraulic machinery. As technology progresses, the future of hydraulic fittings may see innovations that improve performance and adaptability, further solidifying their importance in fluid power applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025