335345435

Oct . 11, 2024 20:12 Back to list

hydraulic hose and fittings manufacturer

Hydraulic Hose and Fittings Manufacturer Essential Components for Industry

In the world of industrial machinery and equipment, hydraulic hoses and fittings are essential components that facilitate the transmission of fluid power. They play a critical role in various industries, from construction to manufacturing, agriculture to transportation. As a hydraulic hose and fittings manufacturer, understanding the intricacies of these components enables businesses to create reliable and efficient solutions for their customers.

Hydraulic hoses are specially designed tubes that transport hydraulic fluids under high pressure. They are crafted from materials that can withstand extreme conditions, including high temperatures and corrosive substances. The primary function of these hoses is to connect different hydraulic systems, enabling the transfer of power to operate machinery such as excavators, cranes, and agricultural equipment. The performance and longevity of these hoses depend on their construction, including reinforcement layers, operating pressure, and bend radius.

A reputable hydraulic hose manufacturer focuses on high-quality production standards. This involves utilizing advanced technology and materials to ensure that each hose can endure the specific demands of its application. For instance, thermoplastic and rubber are common materials used in hose construction, each offering distinct advantages. Rubber hoses are often more flexible, making them suitable for applications with tight bends, while thermoplastic hoses tend to be lighter and more resistant to abrasion and chemicals.

Fittings are equally crucial in the hydraulic system as they serve as connectors that link hoses to other components such as pumps, valves, and cylinders

. The design and quality of hoses and fittings must be compatible to prevent leaks and failures. Manufacturers typically offer a wide variety of fittings, including couplings, elbows, and adapters, made from durable materials such as steel, stainless steel, or brass to ensure resilience and reliability.hydraulic hose and fittings manufacturer

One of the significant challenges for manufacturers is meeting the varying demands of different industries. Each sector may require specific designs, sizes, and performance standards for hoses and fittings. For instance, the oil and gas industry may demand hoses that can withstand high pressures and are resistant to oil and gas, while the agricultural sector may require hoses that can handle abrasive materials and withstand outdoor conditions.

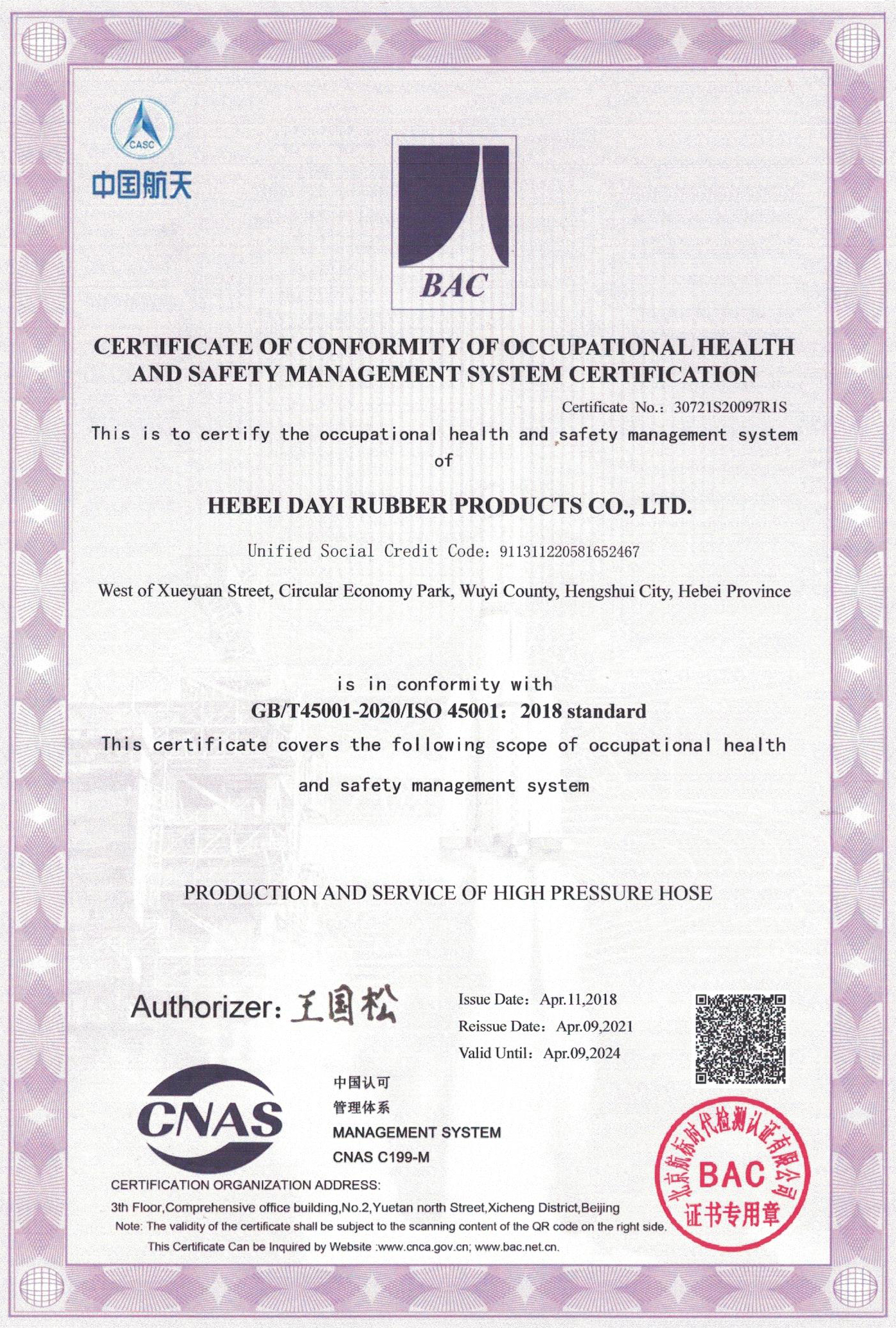

To address these challenges, manufacturers often engage in research and development. This includes innovating new products and improving existing designs to enhance performance and durability. Additionally, ensuring compliance with industry standards and regulations, such as ISO and SAE, is vital to maintaining a reputable brand.

Customer service also plays a significant role in the success of a hydraulic hose and fittings manufacturer. Providing expert advice, quick responses to inquiries, and fast order fulfillment helps build strong relationships with clients. Many manufacturers offer custom solutions, allowing customers to specify their unique needs and receive tailored products that fit their applications perfectly.

In conclusion, a hydraulic hose and fittings manufacturer is an indispensable player in the industrial landscape. By focusing on quality production, understanding industry-specific requirements, and providing exceptional customer service, these manufacturers contribute to the efficiency and reliability of hydraulic systems across various sectors. As technology advances and industries grow, the demand for high-performance hydraulic hoses and fittings will continue to increase, underscoring the importance of excellence in manufacturing practices.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025