335345435

Oct . 13, 2024 12:52 Back to list

hydraulic hose and fitting manufacturers

The Impact of Hydraulic Hose and Fitting Manufacturers on Industrial Efficiency

Hydraulic systems play a crucial role in various industries, powering equipment from construction machinery to agricultural implements. At the heart of these systems are hydraulic hoses and fittings, which ensure the safe and efficient transfer of fluid under high pressure. The manufacturers of hydraulic hoses and fittings are therefore integral to the overall performance of hydraulic systems, influencing efficiency, safety, and operational costs.

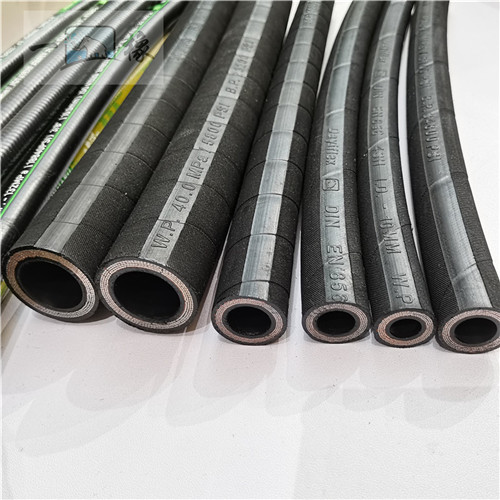

Hydraulic hoses are flexible tubes designed to transport hydraulic fluids between components, while fittings serve as connectors between hoses and other hydraulic components. Together, they form a vital part of any hydraulic system. Manufacturers in this sector focus on innovation and quality, developing products that can withstand the demanding conditions of industrial applications. High-pressure hoses must be crafted from durable materials, often reinforced with multiple layers to prevent failure under extreme conditions.

One of the primary considerations for manufacturers is the choice of materials. High-quality rubber, thermoplastics, and even steel braiding are commonly used to enhance the durability and performance of hydraulic hoses. Manufacturers are increasingly adopting advanced materials and technologies to improve resistance to abrasion, weathering, and chemical exposure. This is particularly relevant in industries such as agriculture where hoses may be subjected to various environmental elements.

hydraulic hose and fitting manufacturers

In addition to material selection, the design and engineering of hydraulic fittings are equally critical. These fittings must provide a secure and leak-proof connection to prevent fluid loss, which can lead to system inefficiencies and safety hazards. Manufacturers invest in precision engineering to ensure that each fitting meets the stringent quality standards required for high-pressure operations. Computer-aided design (CAD) tools are often employed to optimize fitting designs, ensuring they are both functional and cost-effective.

Another important aspect of the hydraulic hose and fitting manufacturing industry is compliance with international standards. Products must meet regulations set by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). Compliance not only ensures safety but also assists manufacturers in gaining the trust and loyalty of customers, as well as access to global markets.

Furthermore, sustainability is becoming an increasingly important factor for hydraulic hose and fitting manufacturers. Many companies are investing in eco-friendly materials and processes to reduce their environmental impact. This commitment to sustainability not only addresses regulatory requirements but also resonates with environmentally conscious consumers and industries.

In conclusion, the role of hydraulic hose and fitting manufacturers is critical to the functioning of hydraulic systems across various sectors. By focusing on quality, innovation, and sustainability, these manufacturers not only enhance operational efficiency but also contribute to the safety and reliability of hydraulic equipment. As the industries they serve evolve, so too will the technological advancements in hose and fitting production, ensuring that they continue to meet the changing demands of users worldwide. The ongoing commitment to excellence and innovation in this sector will undoubtedly shape the future of fluid power applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025