335345435

Nov . 04, 2024 22:52 Back to list

hydraulic hose 4sp manufacturers

Understanding Hydraulic Hose 4SP Manufacturers

Hydraulic hoses are critical components in various industries, delivering power through the transmission of fluids under pressure. Among the myriad types of hydraulic hoses, the 4SP hose is particularly noteworthy due to its robust construction and versatility. This article will delve into the significance of hydraulic hose 4SP manufacturers, their offerings, and the essential factors to consider when choosing a supplier.

What is a Hydraulic Hose 4SP?

The designation 4SP refers to a specific type of hydraulic hose characterized by its four layers of reinforcement, typically composed of high-tensile steel wire. This construction enables it to withstand high pressures, often reaching up to 400 bar (approximately 5800 psi), making it suitable for demanding hydraulic systems. The 4SP hose is commonly used in applications such as construction, mining, agriculture, and heavy machinery, where reliability and durability are paramount.

The Role of Manufacturers

Manufacturers of hydraulic hose 4SP play a pivotal role in ensuring quality and reliability in various hydraulic applications. The production process involves sophisticated technology and adherence to international standards, such as ISO and SAE, which guarantee that the hoses can endure the rigorous conditions under which they operate. Reputable manufacturers invest significantly in research and development to design hoses that can perform consistently, reduce the chances of failure, and extend the overall lifespan of hydraulic systems.

Key Features Offered by 4SP Manufacturers

1. High-Pressure Resistance 4SP hoses are designed to handle extremely high pressures, making them suitable for heavy-duty applications. Manufacturers often provide detailed specifications, including burst pressure ratings, to help users select the right hose for their needs.

2. Temperature Tolerance Many 4SP hoses can operate effectively in a wide range of temperatures, both hot and cold. This ability is crucial in environments where temperature fluctuations are common. Manufacturers typically offer products that maintain performance in conditions ranging from -40°C to 100°C (-40°F to 212°F).

3. Custom Solutions Leading manufacturers understand that different industries have varying requirements. As such, many provide customizable services, allowing clients to specify lengths, diameters, and fittings that best suit their systems.

hydraulic hose 4sp manufacturers

4. Durability The materials used in the construction of 4SP hoses are selected not only for their strength but also for their resistance to abrasion, weather, and chemicals. This durability ensures that the hoses can withstand the demanding conditions of industrial environments.

5. Compliance and Certification Manufacturers often hold various certifications that affirm their commitment to quality and safety. Customers can benefit from knowing that they are receiving products that meet stringent industry standards.

Choosing the Right Manufacturer

When selecting a hydraulic hose 4SP manufacturer, several factors should be considered

- Experience and Reputation Established manufacturers often have a proven track record. Researching customer reviews and industry reputation can provide insights into a manufacturer’s reliability.

- Quality Assurance Processes Understanding a manufacturer's quality control procedures can help ensure that the hoses produced are of the highest standard.

- Technical Support A responsive technical support team can be invaluable, especially in troubleshooting and ensuring the right products are selected for specific applications.

- Pricing and Warranty Competitive pricing is essential, but it shouldn’t come at the cost of quality. Additionally, a good warranty can provide further assurance of the hose quality.

Conclusion

Hydraulic hose 4SP manufacturers play a critical role in supplying high-performance, reliable hoses for various applications. By understanding the features these manufacturers offer and the factors to consider when choosing a supplier, businesses can make informed decisions that enhance the efficiency and safety of their hydraulic systems. Investing in quality hoses is paramount for operational success, making the partnership with a reputable manufacturer an essential component of any hydraulic application.

-

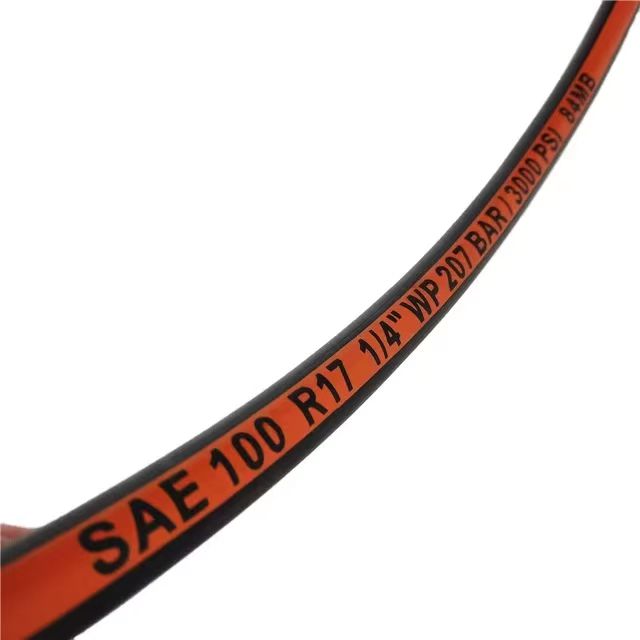

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025