335345435

Sep . 15, 2024 04:35 Back to list

Hydraulic Hose Pipe Fittings - High-Quality Connectors for Efficient Fluid Transfer

Understanding Hydraulic Hose Pipe Fittings

Hydraulic systems are integral to many industrial applications, from construction machinery to automotive manufacturing. At the core of these systems is the hydraulic hose and pipe fittings, which play a crucial role in ensuring that hydraulic fluids are transported efficiently and safely under high pressure.

What are Hydraulic Hose Pipe Fittings?

Hydraulic hose pipe fittings are components that connect hoses or pipes in a hydraulic system. These fittings create a secure, leak-proof connection that allows hydraulic fluid to flow between various components, such as pumps, cylinders, and valves. The fittings come in various shapes and sizes, designed to fit specific hoses and systems, and are made from durable materials such as steel, brass, or plastic.

Types of Hydraulic Hose Pipe Fittings

There are several types of hydraulic hose fittings, each serving a unique purpose

1. NPT Fittings (National Pipe Tapered) These fittings have a tapered thread that allows them to screw into a corresponding fitting, creating a tight seal. NPT fittings are commonly used in applications where the connection is exposed to vibration or pressure.

2. BSP Fittings (British Standard Pipe) Similar to NPT, BSP fittings come in both tapered and parallel threads. They are widely used in Europe and are suitable for low-pressure applications.

3. JIC Fittings (Joint Industry Council) JIC fittings have a 37-degree flare that provides a reliable seal. They are often used in high-pressure hydraulic systems, providing a robust connection.

hydraulic hose pipe fittings pdf

4. Metric Fittings These fittings conform to international standards and are found mainly in European equipment. They provide a reliable connection and are commonly used in hydraulic systems.

5. Quick Disconnect Fittings These are designed for easy attachment and detachment without tools, allowing for quick maintenance or equipment changeover.

Importance of Choosing the Right Fittings

Selecting the appropriate hydraulic hose pipe fittings is crucial for the efficiency and safety of hydraulic systems. The wrong fitting can lead to leaks, which not only waste hydraulic fluid but can also pose significant safety risks. Factors to consider when choosing fittings include

- Pressure Rating Ensure that the fittings can withstand the pressure of the hydraulic system. - Compatibility The fittings must match the hose and equipment specifications. - Material Choose materials that can handle the operating environment, including temperature, exposure to chemicals, and potential corrosion.

Installation and Maintenance

Proper installation of hydraulic hose pipe fittings is essential to avoid leaks and system failures. It is vital to follow the manufacturer’s guidelines and utilize the right tools for the job. Regular inspection and maintenance of fittings are also necessary to ensure that they remain in good working order. Look for signs of wear, rust, or leaks, and replace any damaged fittings promptly.

Conclusion

In conclusion, hydraulic hose pipe fittings are vital components in hydraulic systems, ensuring efficient fluid transfer and system reliability. By understanding the types of fittings available and their proper applications, users can maintain safe and efficient hydraulic systems. Proper installation and routine maintenance will extend the lifespan of the fittings and the overall hydraulic system, ensuring optimal performance in various industrial applications.

-

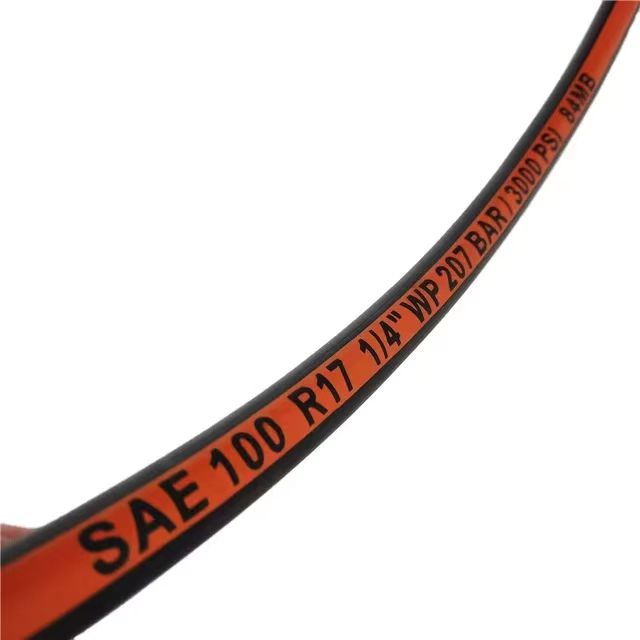

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025