335345435

Oct . 04, 2024 10:35 Back to list

high quality hydraulic hose crimping machine factories

Understanding High-Quality Hydraulic Hose Crimping Machine Factories

In today’s industrial landscape, the demand for high-quality hydraulic hose crimping machines is on the rise. These machines play a critical role in various sectors, including construction, automotive, and manufacturing, making them integral to the operation of hydraulic systems. Consequently, the factories that produce these machines have gained significant attention. This article explores the significance, features, and advancements related to high-quality hydraulic hose crimping machine factories.

The Importance of Hydraulic Hose Crimping Machines

Hydraulic hoses are essential components in transferring fluid under pressure in hydraulic systems. Crimping machines ensure that the hose ends are securely attached to fittings, preventing leaks and ensuring optimal performance. High-quality crimping machines not only enhance the reliability of hydraulic systems but also contribute to the safety and efficiency of operations. Factories producing these machines must adhere to stringent quality control measures to ensure that their products meet industry standards.

Key Features of High-Quality Crimping Machines

1. Robust Construction High-quality crimping machines are built with durable materials that withstand the rigors of frequent use. The frame and components are often designed to resist wear and tear, ensuring a long service life.

2. Precision Engineering Accurate crimping is crucial for the efficiency of hydraulic systems. High-quality crimping machines employ advanced technology and precision engineering to deliver consistent crimping results. This includes features such as digital displays for monitoring pressure and crimping parameters.

3. Versatility Leading manufacturers provide machines that can handle a wide range of hose sizes and types. This versatility makes them suitable for various applications, from small-scale workshops to large manufacturing plants.

4. User-Friendly Design Modern crimping machines are designed with the operator in mind. Features like intuitive controls, ergonomic designs, and easy maintenance protocols help streamline the crimping process, enhancing productivity.

high quality hydraulic hose crimping machine factories

5. Safety Standards High-quality factories prioritize safety by implementing features that minimize risks during operation. This includes emergency stop functions, protective guards, and safety interlocks.

Advancements in Hydraulic Hose Crimping Technology

As technology continues to evolve, so do the capabilities of hydraulic hose crimping machines. Recent advancements include

- Smart Technology Integration Many modern machines now incorporate IoT capabilities, allowing for real-time monitoring and remote control. This innovation enhances operational efficiency and helps in predictive maintenance, minimizing downtime.

- Energy Efficiency With growing environmental concerns, manufacturers have focused on creating energy-efficient machines. This not only reduces operational costs but also lessens the environmental impact.

- Automated Systems Advancements in automation technology have led to the development of fully automated crimping systems, enabling high-volume production with minimal human intervention.

Conclusion

High-quality hydraulic hose crimping machine factories are pivotal in ensuring the production of reliable and efficient crimping machines. By focusing on robust construction, precision engineering, and innovative technology, these factories contribute significantly to the performance and safety of hydraulic systems across various industries. As the demand for such machines continues to grow, factory standards will likely rise, leading to even more advanced solutions tailored to meet the diverse needs of modern manufacturing and engineering challenges. Whether for small workshops or large-scale production, the role of these factories remains unparalleled, driving efficiency and safety in hydraulic operations.

-

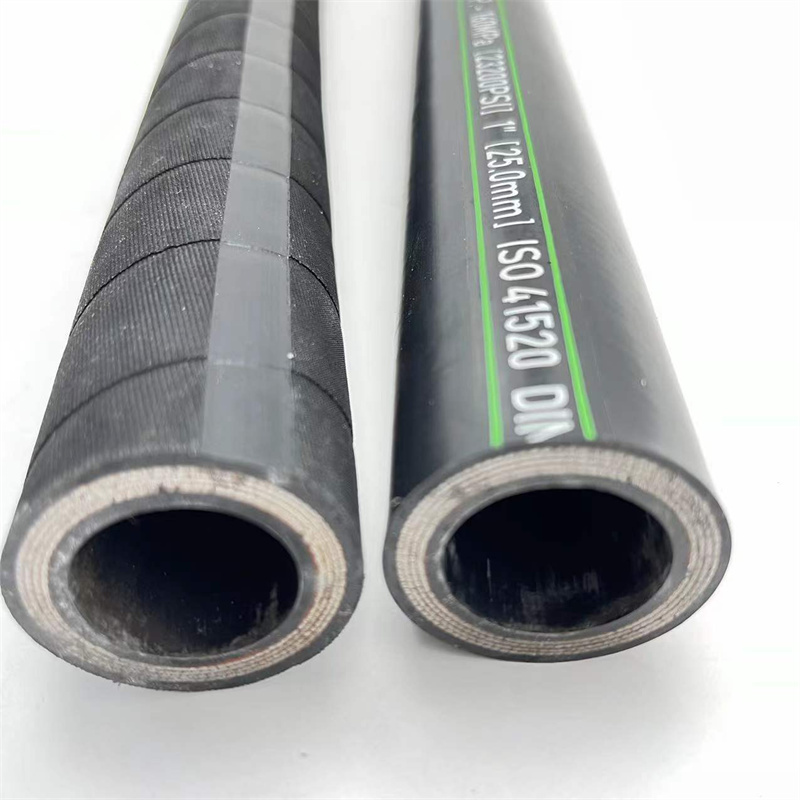

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025