335345435

Nov . 07, 2024 07:23 Back to list

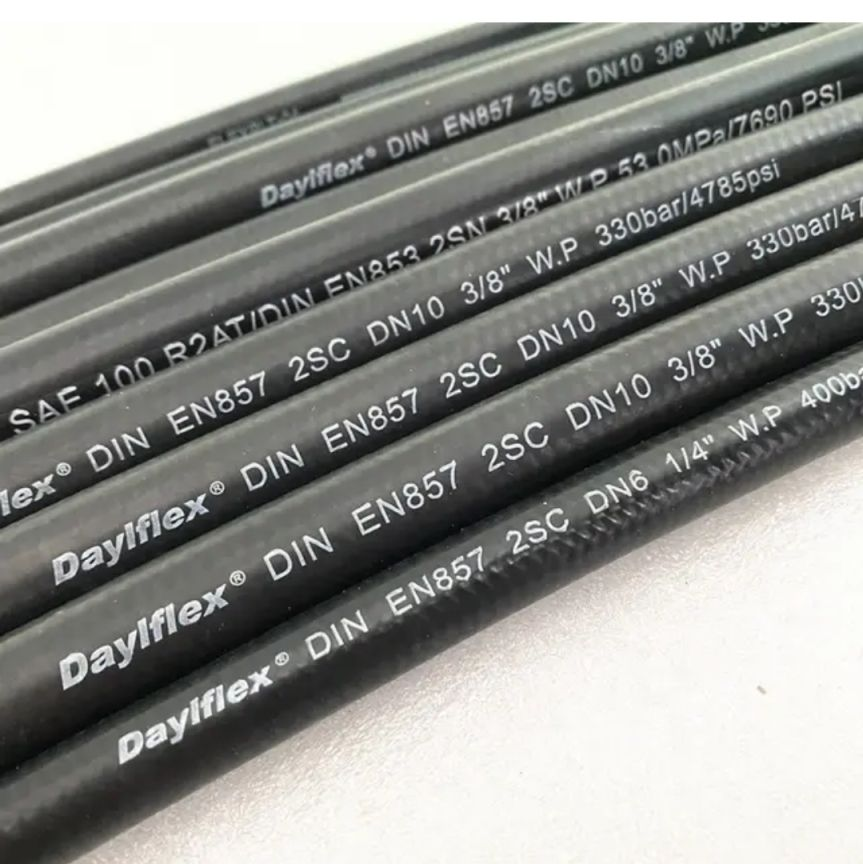

High-strength steel wire braided hydraulic hose suppliers for industrial applications and machinery

Understanding High-Pressure Steel Wire Braided Hydraulic Hose Manufacturers

In various industrial applications, hydraulic systems play a crucial role in transmitting power through pressurized fluids. An essential component of these systems is the hydraulic hose, particularly the high-pressure steel wire braided hydraulic hose, known for its durability, flexibility, and ability to withstand extreme pressures. This article will delve into the significance of these hoses, the manufacturing process, and some of the leading manufacturers in the industry.

What is a High-Pressure Steel Wire Braided Hydraulic Hose?

A high-pressure steel wire braided hydraulic hose consists of an inner tube, reinforced with steel wire and covered by an outer layer. The inner tube is typically made from synthetic rubber, which is resistant to oils and other chemicals, ensuring long-term performance and reliability. The steel wire braid reinforcement provides exceptional tensile strength and allows the hose to handle high-pressure situations—up to several thousand PSI, depending on the hose's specifications.

These hoses are essential in diverse sectors such as construction, agriculture, mining, and automotive industries, where hydraulic machinery and equipment are prevalent. Their robust construction resists wear and tear, making them suitable for rigorous applications.

The Manufacturing Process

The production of high-pressure steel wire braided hydraulic hoses is a meticulous process that involves several steps

1. Material Selection The quality of materials is paramount. Manufacturers source high-grade rubber for the inner tube, which must be resistant to oil and heat. The steel wire used for braiding also plays a critical role; it must be strong enough to endure high pressures without failure.

2. Extrusion of the Inner Tube The first step in manufacturing is to extrude the rubber to form the inner tube. This tube must be uniform in thickness to maintain consistency under pressure.

3. Braiding Once the inner tube is prepared, the next step involves braiding the steel wire around the tube. This is a complex process that requires precision machinery. The braiding angle and density of the wire affect the hose's strength and flexibility.

high pressure steel wire braided hydraulic hose manufacturers

5. Testing Quality control is crucial in this industry. Finished hoses undergo rigorous testing to ensure they meet specific pressure ratings and standards. Leak tests, impulse tests, and burst tests are common methods employed to verify the integrity of the hose.

6. Certification Many manufacturers seek certification for their products from recognized standards organizations. Certifications such as ISO 9001 ensure that the manufacturing process and end products meet global quality standards.

Leading Manufacturers

Several manufacturers have established themselves as leaders in the production of high-pressure steel wire braided hydraulic hoses. These companies leverage advanced technology and innovative practices to deliver high-quality products.

1. Parker Hannifin Recognized worldwide, Parker Hannifin offers a comprehensive range of hydraulic hoses designed for different applications. Their steel wire braided hoses are renowned for their reliability and performance.

2. Continental AG A major player in the field, Continental AG produces hydraulic hoses that meet stringent safety standards. Their products are extensively used in the automotive and industrial sectors.

3. Gates Corporation Gates is known for pioneering many advancements in hose manufacturing. Their high-pressure hydraulic hoses are designed to cater to the increasing demand for efficiency and performance in hydraulic applications.

4. Goodyear With decades of experience, Goodyear manufactures robust hydraulic hoses, including those with steel wire braiding. They are known for their commitment to innovation and quality.

5. Eaton Corporation Eaton provides a broad spectrum of hydraulic solutions, including high-pressure hoses. Their emphasis on engineering excellence ensures that their products meet the needs of a diverse range of industries.

Conclusion

High-pressure steel wire braided hydraulic hoses are integral to the efficient functioning of hydraulic systems across various sectors. The strength and flexibility of these hoses come from meticulous manufacturing processes and high-quality materials. As industries continue to grow and evolve, the demand for durable and reliable hydraulic hoses will only increase. Manufacturers that prioritize quality control, innovation, and customer satisfaction will undoubtedly lead the market, ensuring that hydraulic systems operate smoothly and effectively.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025