335345435

Nov . 14, 2024 17:35 Back to list

high pressure stainless steel braided hose

Understanding High Pressure Stainless Steel Braided Hoses

High pressure stainless steel braided hoses are essential components in various industrial applications, designed to withstand significant pressures while providing flexibility, durability, and resistance to corrosion. These hoses are widely utilized in sectors such as oil and gas, automotive, aerospace, and manufacturing, where performance and safety are paramount.

Structure and Design

The structure of high pressure stainless steel braided hoses typically comprises an inner tube made of flexible materials like rubber or thermoplastic. This inner layer is then reinforced by a braided layer of stainless steel wire, which provides exceptional strength and protection against external damage. The stainless steel braid not only enhances the pressure rating of the hose but also makes it resistant to abrasion, cuts, and adverse environmental conditions.

Benefits

One of the primary advantages of using high pressure stainless steel braided hoses is their ability to handle extreme pressures without compromising safety

. This makes them ideal for transporting fluids such as oil, water, and chemicals in high-demand applications. The stainless steel construction also ensures longevity, often outperforming traditional rubber hoses that can degrade over time due to exposure to chemicals or high temperatures.Moreover, these hoses are highly flexible, allowing for easy installation in tight spaces. Their flexibility, combined with their high-pressure rating, makes them suitable for dynamic systems where movement is a factor. They can also tolerate temperature fluctuations, maintaining integrity in high heat conditions.

high pressure stainless steel braided hose

Applications

High pressure stainless steel braided hoses are commonly found in a multitude of applications. In the automotive industry, they are used for fuel lines, hydraulic systems, and cooling systems, where reliability is crucial. In the aerospace sector, their lightweight yet sturdy nature makes them ideal for various fluid transfer needs in aircraft systems.

In industrial settings, these hoses are vital for chemical processing, where the transportation of corrosive substances requires materials that can withstand harsh conditions. Additionally, the oil and gas industry relies heavily on these hoses for both upstream and downstream processes, where fluid transfer under high pressure is a regular occurrence.

Maintenance and Safety

While high pressure stainless steel braided hoses are robust, regular maintenance is essential to ensure their lifespan. Operators should routinely check for signs of wear, leaks, or fittings issues. It is also crucial to follow manufacturer guidelines for installation and operation to maximize safety and performance.

In conclusion, high pressure stainless steel braided hoses are an indispensable part of modern industrial operations. Their unique combination of strength, flexibility, and resistance to corrosion makes them suitable for a wide range of high-pressure applications. Understanding their construction, benefits, and appropriate uses can help businesses optimize their processes, ensuring safety and efficiency in operations.

-

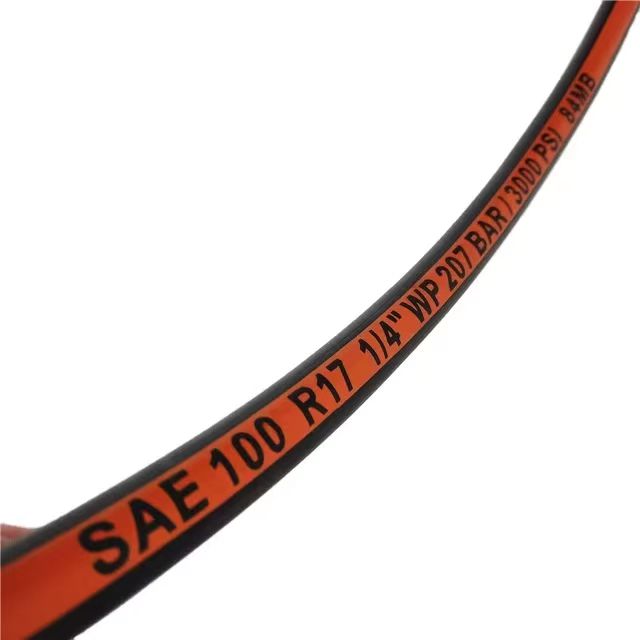

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025