335345435

Oct . 11, 2024 17:49 Back to list

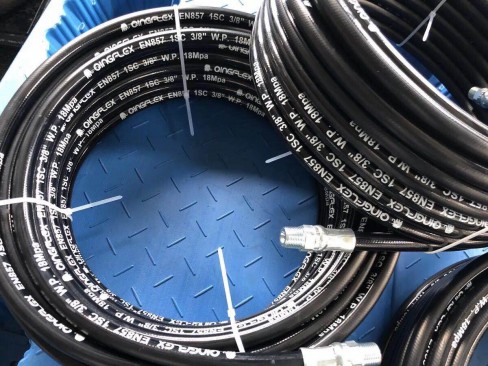

high pressure hydraulic hose ferrules factory

The Importance of High Pressure Hydraulic Hose Ferrules in Industrial Applications

Hydraulic systems play a crucial role in numerous industries such as manufacturing, construction, and agriculture. A key component of these systems is the hydraulic hose, which facilitates the transfer of fluids under high pressure. However, the effectiveness and safety of hydraulic hoses can greatly depend on the quality of their connections and fittings, particularly the ferrules. This article explores the significance of high pressure hydraulic hose ferrules, their manufacturing processes, and their applications in various industries.

What are Hydraulic Hose Ferrules?

Ferrules are metal components that serve to secure the ends of hydraulic hoses and provide a robust connection point for fittings. They are critical in ensuring the hose can withstand the pressures of operation, often exceeding thousands of PSI (pounds per square inch). By crimping the ferrule onto the hose and coupling, a reliable and leak-free seal is created, which is vital for the safety and efficiency of hydraulic systems.

Manufacturing of High Pressure Hydraulic Hose Ferrules

The production of high pressure hydraulic hose ferrules involves precision engineering and stringent quality control measures. Typically, ferrules are made from high-strength materials such as stainless steel, carbon steel, or brass, which are chosen for their durability and resistance to corrosion.

1. Material Selection High-quality raw materials are essential for producing ferrules that can handle high pressures and harsh environmental conditions. For instance, stainless steel ferrules are often preferred in marine applications due to their corrosion resistance.

2. Precision Machining The manufacturing process involves advanced machining techniques to achieve the exact dimensions required for a perfect fit. This includes cutting, turning, and milling processes that ensure each ferrule meets industry specifications.

3. Heat Treatment and Surface Finish To enhance strength and durability, many ferrules undergo heat treatment followed by surface finishing processes such as plating or coating. These treatments not only improve the ferrule's lifespan but also its resistance to wear, tear, and environmental factors.

high pressure hydraulic hose ferrules factory

4. Quality Assurance Manufacturers employ rigorous testing procedures to ensure that each ferrule can withstand high pressure. This may include hydraulic pressure testing and dimensional checks to confirm adherence to safety standards.

Applications of High Pressure Hydraulic Hose Ferrules

High pressure hydraulic hose ferrules are indispensable in various applications across different sectors

- Construction In construction equipment, such as excavators and bulldozers, hydraulic hoses facilitate the operation of various functions like lifting, digging, and material handling. Ferrules ensure these hoses remain connected under substantial pressure, protecting both machinery and operators.

- Agriculture Modern agricultural machines, including tractors and harvesters, utilize high pressure hydraulic systems to enhance productivity. Ferrules play a critical role in maintaining the integrity of hydraulic lines that power these sophisticated machines.

- Manufacturing In manufacturing, hydraulic systems are often used for pressing, molding, and cutting operations. The use of high pressure hydraulic hose ferrules ensures uninterrupted machinery operation, which is essential for maintaining production efficiency.

- Transportation Hydraulic systems are also prevalent in transport vehicles, including buses and trucks, where they control braking and steering systems. Ferrules must withstand high pressure to prevent catastrophic failures that could lead to accidents.

Conclusion

The role of high pressure hydraulic hose ferrules cannot be overstated. As industries continue to rely on advanced hydraulic systems for various applications, the demand for reliable and high-quality ferrules will only grow. Manufacturers who focus on precision, material quality, and rigorous testing are essential in providing the robust solutions needed for safe and effective hydraulic operations. Investing in top-notch hydraulic hose ferrules enhances the overall reliability of hydraulic systems, ultimately leading to increased efficiency and safety across various industrial applications. Whether in construction, agriculture, manufacturing, or transportation, the importance of these small but mighty components is undeniable in the realm of high pressure hydraulics.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025