335345435

Aug . 16, 2024 17:42 Back to list

High-Quality OEM Suction and Delivery Hose Manufacturing for Diverse Applications

Understanding OEM Suction and Delivery Hose Factories

In today’s industrial landscape, the demand for high-quality hoses is ever-increasing. OEM suction and delivery hose factories have emerged as critical players in this sector, providing crucial components for various applications, including agriculture, construction, and manufacturing. This article explores the significance of these factories, the technology they employ, and the growing market demands driving their evolution.

What Does OEM Mean?

OEM stands for Original Equipment Manufacturer. In the context of suction and delivery hoses, OEM factories produce hoses that meet the specifications of other companies that integrate these hoses into their products or systems. Essentially, these factories not only manufacture hoses but also ensure that the products adhere to stringent quality standards set by their clients.

The Role of Suction and Delivery Hoses

Suction and delivery hoses are essential for the transport of different substances. Suction hoses are designed to draw fluids from a source, while delivery hoses are meant to discharge the fluids. This could involve water, chemicals, or other materials. Reliability and durability are critical in applications where these hoses are used, as failures can lead to significant operational disruptions, safety hazards, and financial losses.

Advanced Manufacturing Techniques

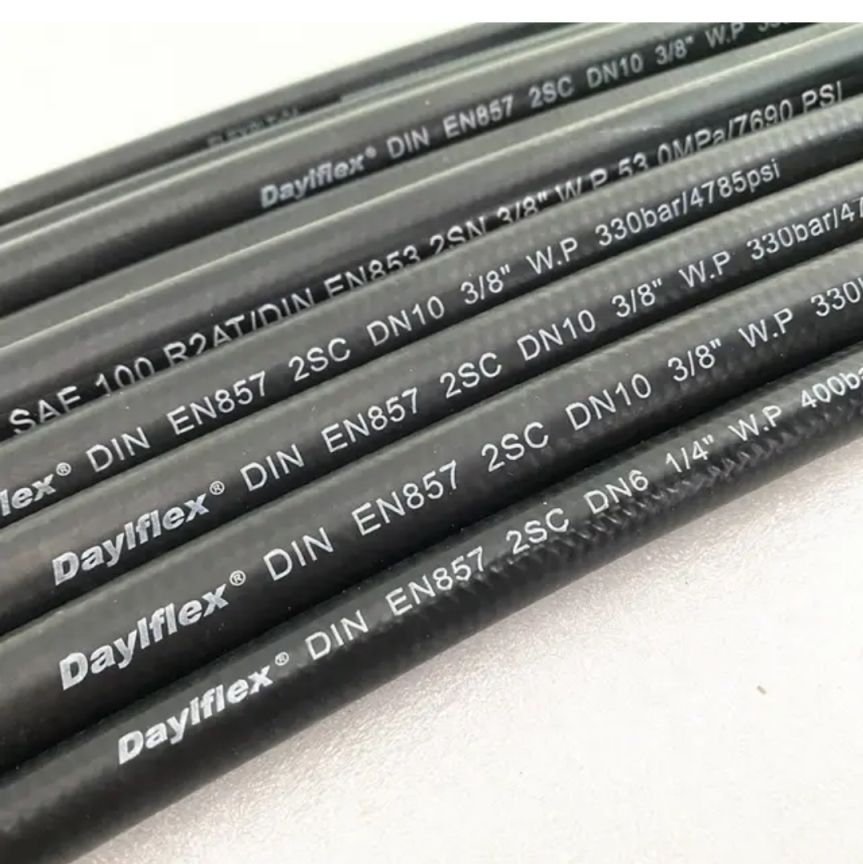

OEM suction and delivery hose factories utilize advanced manufacturing techniques to ensure the quality and performance of their products. Technologies such as extrusion, crimping, and reinforcement through various materials (like fabric or wire) are commonly used. The selection of materials is crucial; hoses are often made from synthetic rubber, PVC, or other composites that provide resistance to abrasion, weathering, and chemicals.

oem suction and delivery hose factories

Additionally, modern factories leverage automation and robotics to enhance precision and reduce manufacturing time. These technologies enable factories to produce hoses at scale while maintaining high-quality standards. Quality control measures such as pressure testing, durability testing, and compliance with international standards (e.g., ISO, ASTM) are integral to the manufacturing process.

Growing Market Demands

As industrial activities expand globally, the demand for reliable OEM suction and delivery hoses is on the rise. The construction sector, which requires hoses for water and concrete delivery, is one of the largest consumers. Additionally, the agricultural sector relies on these hoses for irrigation and fluid management.

Furthermore, environmental concerns and the push for sustainability have prompted OEM factories to innovate. There is an increasing need for hoses that are not only durable but also made from eco-friendly materials. As companies shift towards greener practices, manufacturers are investing in research and development to create sustainable hoses that meet these needs.

Challenges Faced by OEM Factories

Despite the opportunities, OEM suction and delivery hose factories face several challenges. Fluctuating raw material prices can impact production costs, while the rapid pace of technological advancement requires continuous investment in equipment and training. Additionally, the global supply chain disruptions witnessed recently have highlighted vulnerabilities, prompting factories to reconsider their sourcing strategies and inventory management.

Conclusion

OEM suction and delivery hose factories play an integral role in the supply chain of various industries. Their ability to produce high-quality, reliable hoses that meet specific client requirements positions them as essential contributors to industrial operations. As market demands evolve, these factories must adapt to technological advancements and sustainability concerns, ensuring they remain at the forefront of innovation. With the right strategies in place, OEM factories can look forward to a robust future in the industrial sector.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025