335345435

Jul . 30, 2024 05:30 Back to list

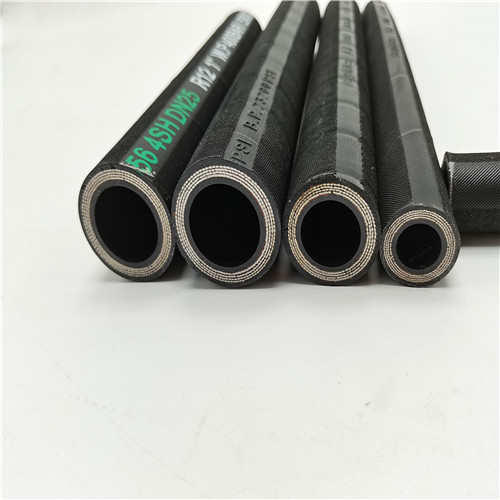

High-Quality OEM Black Hydraulic Hose for Reliable Performance in Various Applications

Understanding OEM Black Hydraulic Hoses Specifications and Applications

Hydraulic systems are critical components in various industries, including construction, manufacturing, and automotive sectors. Among the essential parts of these systems are hydraulic hoses, which play a crucial role in transmitting fluid power. Specifically, OEM black hydraulic hoses have gained popularity due to their quality, reliability, and specific design for Original Equipment Manufacturers (OEMs). This article will delve into the features, specifications, and applications of OEM black hydraulic hoses.

What is an OEM Black Hydraulic Hose?

OEM stands for Original Equipment Manufacturer, which signifies that the product is designed and manufactured by a company that produces the original components for a machine or vehicle. An OEM black hydraulic hose is a high-quality rubber or synthetic hose specifically designed to meet the exact specifications of hydraulic systems in machinery and equipment. These hoses are often black in color due to the addition of carbon-black pigments that enhance their durability and UV resistance.

Key Specifications

1. Material OEM black hydraulic hoses are typically made from reinforced rubber or thermoplastic materials. These materials are chosen for their excellent resistance to hydraulic fluids, temperature variations, and environmental conditions.

2. Pressure Ratings One of the critical specifications of hydraulic hoses is their pressure rating, which determines the maximum pressure the hose can withstand without bursting. OEM black hydraulic hoses come with a range of pressure ratings, from low to high, depending on the specific application and requirements.

3. Diameter The inner diameter of the hose is essential for determining the flow rate of hydraulic fluid. OEM hoses are available in various diameters to suit different systems and applications, ensuring that the appropriate amount of fluid can be transferred without restrictions.

4. Temperature Range The durability of hydraulic hoses is often tested against extreme temperatures. OEM black hydraulic hoses are engineered to operate effectively in both high and low temperature conditions, maintaining flexibility and strength.

oem black hydraulic hose

5. Reinforcement Layers To enhance the strength and performance of hydraulic hoses, OEM versions often include several layers of reinforcement, such as steel wire braiding or spiral wraps. These layers provide additional protection against internal pressure and external abrasion.

Applications

OEM black hydraulic hoses are used in a variety of applications, such as

1. Construction Equipment In heavy machinery, such as excavators and bulldozers, hydraulic hoses facilitate the operation of hydraulic cylinders and motors. They must withstand rigorous conditions, including high pressure and variable weather.

2. Agricultural Machinery Tractors and other farming equipment rely on hydraulic systems for various functions, from lifting equipment to steering. OEM black hydraulic hoses ensure efficiency and reliability in the field.

3. Automotive Many vehicles utilize hydraulic systems for brakes, steering, and suspension. OEM black hydraulic hoses are essential for ensuring these systems operate smoothly and safely.

4. Industrial Machinery In manufacturing settings, hydraulic hoses are used to power conveyor belts, presses, and other machinery. OEM hoses are crucial for maintaining productivity and ensuring safety standards are met.

Conclusion

In conclusion, OEM black hydraulic hoses are indispensable in numerous industries due to their design, durability, and reliability. By meeting specific OEM standards, these hoses ensure that hydraulic systems function efficiently and safely across a broad range of applications. Choosing the right OEM black hydraulic hose for a particular application is critical to optimizing performance and minimizing downtime. With ongoing advancements in material science and engineering, the future of hydraulic hoses looks bright, promising even greater capabilities and efficiencies for hydraulic systems globally.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025