335345435

Aug . 15, 2024 02:11 Back to list

High-Performance Teflon Hoses for Various Industrial Applications from China Eaton Solutions

The Rise of China Eaton Teflon Hose A Comprehensive Overview

In recent years, the demand for high-performance hoses across various industries has surged significantly, thanks in part to advancements in material science and engineering. Among the most notable innovations is the China Eaton Teflon hose, known for its exceptional durability, chemical resistance, and versatility. This article explores the features, applications, manufacturing process, and market trends related to the China Eaton Teflon hose, highlighting its importance in modern industrial applications.

What is Teflon Hose?

Teflon, a registered trademark of Chemours, refers to polytetrafluoroethylene (PTFE), a synthetic fluoropolymer renowned for its unique properties. Teflon hoses are typically designed to transport liquids or gases in environments where other hoses may fail due to high temperatures, chemical exposure, or pressure. The China Eaton Teflon hose stands out for its robust construction, which often includes a stainless steel braid for added strength and flexibility, allowing it to withstand severe conditions.

Features and Benefits

The China Eaton Teflon hose boasts a myriad of features that make it a preferred choice across various sectors

1. Chemical Resistance The non-reactive nature of Teflon allows it to handle a wide range of aggressive chemicals – from acids to solvents – making it ideal for industries such as pharmaceuticals, chemical processing, and food services.

3. Low Friction The smooth inner surface of Teflon reduces friction, improving flow rates and contributing to energy efficiency when transporting fluids.

4. Flexibility and Durability Teflon hoses retain flexibility under various operating conditions while resisting kinking and fatigue, resulting in a longer lifespan and reduced maintenance costs.

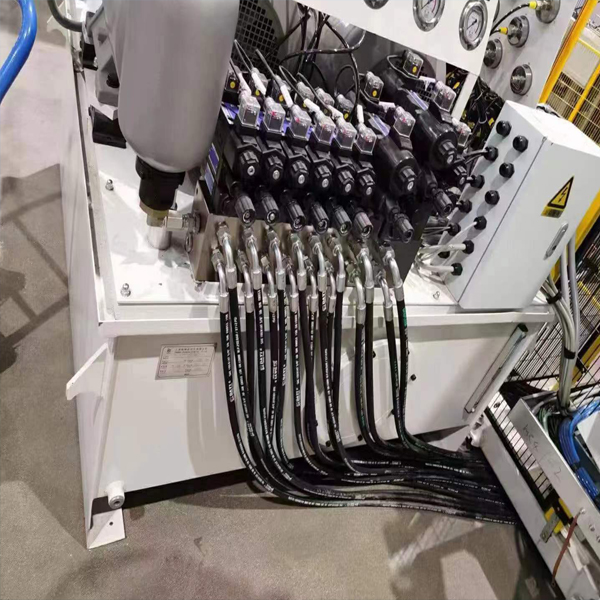

china eaton teflon hose

5. Wide Range of Sizes China Eaton provides Teflon hoses in a variety of diameters and lengths, thus catering to specific customer requirements and applications.

Applications

The versatility of China Eaton Teflon hoses translates into a broad spectrum of applications. Industries such as aerospace, automotive, petrochemical, and food processing rely heavily on these hoses for critical operations. For instance

- Aerospace Teflon hoses are used in fuel and hydraulic systems due to their resistance to extreme temperatures and chemicals. - Pharmaceuticals The ability to maintain cleanliness while handling sensitive chemicals makes Teflon hoses essential in drug manufacturing processes. - Food and Beverage Teflon hoses are ideal for transporting food products safely, ensuring no contamination occurs.

Manufacturing Process

The production of China Eaton Teflon hoses involves several sophisticated steps to ensure quality and performance. Typically, the process starts with the extrusion of Teflon into a tube, which is then reinforced with stainless steel braid or other materials to enhance strength. Rigorous testing and quality control procedures are implemented throughout the manufacturing process to meet international standards.

Market Trends

As industries evolve, the demand for specialized hoses like those manufactured by China Eaton continues to grow. Increased awareness of chemical safety, stringent environmental regulations, and the drive for efficiency fuel the need for high-quality hoses. Moreover, the push for innovation in manufacturing processes and materials is likely to spur further growth in the Teflon hose market.

Conclusion

The China Eaton Teflon hose exemplifies the intersection of technology and industrial needs, offering a solution that meets the demanding requirements of various sectors. With its impressive range of features, durability, and adaptability, the Teflon hose stands as a testament to the advancements in hose technology, paving the way for safer and more efficient operations across the globe. As the market continues to expand, we can expect further innovation and improvements in the Teflon hose sector, maintaining its critical role in industrial applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025