335345435

Jul . 26, 2024 00:02 Back to list

High-Performance PTFE Hose Supplier for High Pressure Applications and Reliable Fluid Transfer Solutions

High Pressure PTFE Hose Supplier Ensuring Quality and Performance

When it comes to handling high-pressure applications, selecting the right materials is crucial for both safety and efficiency. This is where high pressure PTFE (Polytetrafluoroethylene) hoses come into play. As companies look for reliable solutions to their fluid transfer needs, the demand for quality PTFE hoses has grown, leading to a surge in suppliers specializing in this essential component.

PTFE is known for its outstanding chemical resistance, high thermal stability, and excellent non-stick properties. These characteristics make it an ideal choice for various industries, including chemical processing, pharmaceuticals, food and beverage, and aerospace. High pressure PTFE hoses are engineered to withstand extreme conditions while maintaining integrity and performance, making them invaluable in critical applications.

Key Features of High Pressure PTFE Hoses

1. Temperature Resistance High pressure PTFE hoses can function effectively in extreme temperature ranges, often from -100°F to +500°F (-73°C to +260°C). This versatility allows them to be used in a variety of environments.

2. Chemical Compatibility PTFE is inert to most chemicals, making these hoses suitable for transferring aggressive substances such as acids, solvents, and gases. This property significantly reduces the risk of contamination and ensures safety in chemical processing applications.

3. Flexibility and Durability Despite being high-pressure rated, PTFE hoses offer exceptional flexibility, allowing for easier installation and routing. Coupled with their abrasion resistance, these hoses can withstand harsh environments without the risk of leaks or failures.

4. Pressure Ratings High pressure PTFE hoses are designed to handle substantial pressure, often exceeding 3000 PSI, depending on the construction and size. This capability is vital for industries where pressure performance is critical.

Choosing a High Pressure PTFE Hose Supplier

high pressure ptfe hose supplier

Selecting the right supplier for high pressure PTFE hoses is paramount for ensuring quality and reliability. Here are some factors to consider when choosing a supplier

1. Reputation and Industry Experience Suppliers with a proven track record and extensive experience in the industry are more likely to provide high-quality products. Research customer reviews and case studies to gauge the supplier's reliability.

2. Product Range Look for suppliers that offer a comprehensive range of PTFE hoses, including different sizes, pressure ratings, and configurations. This variety ensures that you can find the right hose for your specific application.

3. Customization Capabilities Different applications may require tailored solutions. A good supplier should have the capability to customize hoses based on your unique requirements, including length, fittings, and other specifications.

4. Certifications and Compliance Ensure that the supplier’s products comply with relevant industry standards and regulations. Certifications such as ISO, FDA, and USP can indicate a commitment to quality and safety.

5. Customer Support and Warranty A reliable supplier should offer excellent customer support, assisting with product selection, installation advice, and troubleshooting. Additionally, warranty options can provide peace of mind regarding the durability of the hoses.

Conclusion

In conclusion, high pressure PTFE hoses are essential components in many industries, and choosing the right supplier can significantly impact the success of your operations. By considering factors such as reputation, product range, and customer support, businesses can ensure they partner with a supplier that provides high-quality products tailored to their needs. As industries continue to evolve, the importance of reliable high pressure PTFE hoses and their suppliers will only grow, underscoring the need for investment in quality and performance.

-

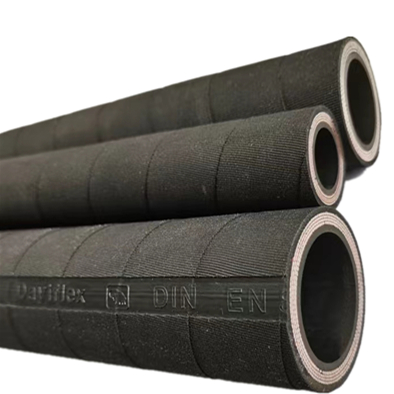

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025